Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

1.Prime quality

2.Competitive price

3.Professional service

4.Prompt delivery & Seaworthy packing

5.Mill Test Certificate

Specification of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

Material: Q235; A36; SS400; ST37; SAE1006/1008; S275JR; Q345,S355JR; 16Mn; ST52 etc.

thickness: 3-30mm, width 10-400mm, length 5-12M

Length: fixed length, random length

Application of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

A)Features of Stainless Steel Flat Bar:

a) The appearance of cold-rolled products gloss is good, beautiful;

b) Excellent high temperature strength;

c) Excellent work-hardening (after processing weakly magnetic)

d) Non-magnetic state solution.

B)Specifications of Stainless Steel Flat Bar:

1. Standard: GB ASTM, JIS, etc.

2. Grade: 200,300,400series

3. Size: 3mm*19mm ~ 12mm*140mm

4. Thickness: from 3mm to 12mm

5. Width: from 19mm to 140mm

6. Shape Manufactured: flat bar

7. Length: 2-6m or as customers' request

8. Surface finish: Black & Pickled & Bright

9. Manufacture technology: cold drawn/cold rolled/hot rolled

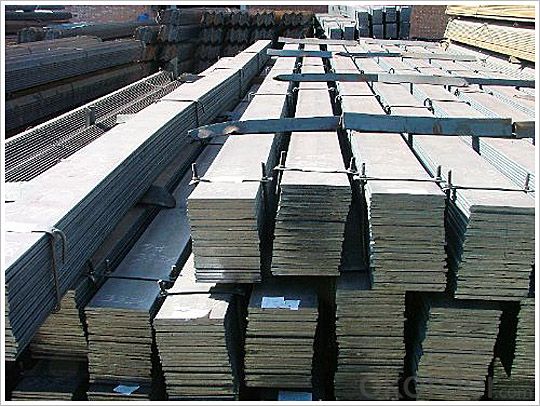

C) Product Photos

- Q:How do steel flat bars resist bending or twisting?

- Steel flat bars resist bending or twisting due to their shape and the properties of the material. The flat shape provides a larger surface area for distributing the applied force, which helps to prevent bending. Additionally, steel is a strong and rigid material, known for its high tensile strength. These properties allow steel flat bars to withstand external forces and resist bending or twisting.

- Q:Where can steel flat bars be purchased?

- There are several sources where one can purchase steel flat bars. These include hardware stores, home improvement centers, metal supply companies, and online retailers. Hardware stores like Home Depot and Lowe's typically have a variety of steel flat bars in different sizes and lengths. Home improvement centers such as Menards or Ace Hardware may also have steel flat bars available for purchase. Metal supply companies specialize in selling various types of metal, including steel flat bars, and usually offer a wide range of sizes and options for custom cutting. Additionally, there are numerous online retailers that sell steel flat bars, providing the convenience of shopping from home and often offering a larger selection and competitive prices. It is recommended to compare prices and quality before making a purchase, ensuring that the steel flat bars meet the required specifications and are sourced from reputable sellers.

- Q:What are the different techniques for joining steel flat bars together?

- There are several techniques for joining steel flat bars together, depending on the specific requirements and applications. Some of the common techniques include welding, bolting, riveting, and adhesive bonding. 1. Welding: Welding is one of the most widely used techniques for joining steel flat bars. It involves melting the edges of the flat bars and fusing them together using heat. Different welding methods, such as arc welding, gas welding, and laser welding, can be used depending on the thickness and composition of the steel bars. 2. Bolting: Bolting is an effective technique for joining steel flat bars, especially when disassembly is required. It involves drilling holes in the flat bars and using bolts, nuts, and washers to secure them together. Bolting provides a strong and reliable connection but may require periodic maintenance to prevent loosening. 3. Riveting: Riveting involves driving a metal pin or rivet through holes drilled in the steel flat bars. The rivet is then deformed on the opposite side, creating a permanent connection. Riveting provides a strong joint and is commonly used in structural applications where high strength and rigidity are required. 4. Adhesive bonding: Adhesive bonding is a technique where a strong adhesive is applied between the surfaces of the steel flat bars to create a bond. This method is suitable for joining thin flat bars or when welding or drilling is not feasible. Adhesive bonding provides a clean and aesthetically pleasing joint but may have limitations in terms of strength and durability. 5. Mechanical fasteners: Mechanical fasteners, such as clips, clamps, or brackets, can be used to join steel flat bars together. These fasteners are designed to hold the flat bars in place without the need for welding or drilling. Mechanical fasteners offer ease of installation and disassembly but may not provide the same level of strength as welding or riveting. It is important to select the appropriate joining technique based on factors such as the intended application, load requirements, design constraints, and the properties of the steel flat bars.

- Q:Can steel flat bars be used for making kitchen utensils?

- When making kitchen utensils using steel flat bars, several factors need to be considered. Firstly, it is essential to use food-grade stainless steel, such as 304 or 316 stainless steel, which are non-reactive and resistant to corrosion. These types of steel are commonly chosen for kitchen utensils as they don't release any harmful substances into the food. Secondly, it is crucial to ensure that the flat bars are appropriately shaped and finished to create safe and functional utensils. They should be cut, bent, and polished to achieve the desired shapes and smooth surfaces. This will minimize any potential safety risks or contamination. Lastly, maintaining the hygiene and safety of the utensils made from steel flat bars requires following proper sanitation and cleaning practices. Regular cleaning, sanitizing, and appropriate storage methods will guarantee that the utensils remain safe to use for food preparation. In conclusion, steel flat bars can be utilized for creating kitchen utensils, but it is vital to use food-grade stainless steel, shape and finish them correctly, and adhere to proper sanitation practices to ensure the safety and functionality of the utensils.

- Q:What are the different methods of bending steel flat bars?

- There are several methods to bend steel flat bars, including using a manual or hydraulic press brake, utilizing a bending machine or roller, applying heat and using a torch or forge, and employing specialized tools such as a bending jig or vise.

- Q:Can steel flat bars be drilled or machined?

- Certainly! Drilling or machining steel flat bars is indeed possible. Steel, being a highly adaptable substance, can be easily manipulated through the utilization of suitable tools and techniques. In the case of drilling, the employment of a drill press or a handheld drill equipped with an appropriate drill bit can effectively penetrate steel flat bars. Additionally, achieving desired shapes or dimensions can be achieved through the use of milling machines, lathes, or CNC machines. Nevertheless, it is crucial to exercise caution by utilizing appropriate cutting tools and lubricants to ensure efficient machining and protect the steel flat bars from any potential damage.

- Q:What are the safety precautions when handling steel flat bars?

- When handling steel flat bars, there are several safety precautions that should be taken to ensure the well-being of individuals involved. 1. Personal Protective Equipment (PPE): It is crucial to wear appropriate PPE to minimize the risk of injuries. This includes gloves, safety glasses, and steel-toed boots to protect yourself from potential cuts, eye injuries, and foot injuries. 2. Lifting Techniques: Steel flat bars can be heavy and bulky, so it is important to use proper lifting techniques to avoid strain or back injuries. Lift with your legs, not your back, and always ask for assistance if the weight is too heavy to handle alone. 3. Storage and Stacking: When storing or stacking steel flat bars, ensure they are properly secured to prevent them from falling or toppling over. Use appropriate storage racks or shelves to keep them organized and avoid any potential hazards. 4. Sharp Edges: Steel flat bars often have sharp edges, so it is essential to be cautious and handle them with care. Avoid dragging or sliding them across surfaces to prevent injuries. Additionally, rounding or deburring the edges can reduce the risk of cuts. 5. Fire Safety: Steel is highly flammable, so it is important to keep the work area clear of any flammable materials and ensure the presence of fire extinguishers. Avoid using steel flat bars near open flames or other sources of ignition. 6. Proper Training: Adequate training and familiarity with handling steel flat bars are essential for safety. Educate yourself and others on the proper techniques and precautions to follow to minimize the potential risks. 7. Regular Maintenance: Inspect the steel flat bars regularly for any signs of damage, such as cracks or corrosion. Damaged bars should be replaced to avoid potential accidents. By implementing these safety precautions, individuals can effectively reduce the risks associated with handling steel flat bars and promote a safer work environment.

- Q:How do you determine the maximum load capacity of a steel flat bar?

- Determining the maximum load capacity of a steel flat bar involves considering several factors. Firstly, the load capacity depends on the material properties of the steel, including its yield strength and tensile strength. These properties can typically be found in engineering handbooks or the manufacturer's specifications. The yield strength represents the maximum stress the steel can withstand before permanent deformation, while the tensile strength indicates the maximum stress it can handle before breaking. Secondly, the dimensions of the flat bar are crucial. The width, thickness, and length of the bar all contribute to its load-carrying capacity. Generally, a wider and thicker bar has a higher load capacity than a narrower and thinner one. The length of the bar also affects its ability to bear loads, as longer bars are more prone to bending and sagging. The type of loading the flat bar will experience is another factor to consider. Different types of loads, such as evenly distributed loads or point loads, have varying effects on the bar's capacity. Additionally, the support conditions at the ends of the bar play a role. Whether the ends are simply supported or fixed will impact the bar's load-bearing ability. Engineers often utilize mathematical equations, such as the Euler-Bernoulli beam theory or the yield strength formula, to determine the maximum load capacity. These equations incorporate the material properties, dimensions, and loading conditions. They provide a way to calculate the maximum load the steel flat bar can withstand without failure. It is important to note that these calculations are based on theoretical assumptions and simplifications. Real-world applications may have additional factors to consider, such as safety factors, environmental conditions, and dynamic loading. Therefore, it is advisable to consult with a qualified engineer or structural analyst to ensure an accurate determination of the maximum load capacity for a specific steel flat bar application.

- Q:Please: hot galvanized flat steel and copper clad steel ground!

- Copper layer adhesion is high: because the copper layer and the surface of the steel is the combination of molecules, so the degree of adhesion is high, in the stranding of synthetic strands, the copper layer will not be damaged, there will be no separation, skin cracking and cracking.

- Q:Are steel flat bars suitable for load-bearing shelves or brackets?

- Load-bearing shelves or brackets can be supported by steel flat bars, as they are known for their strength and durability. Steel is an excellent choice due to its ability to withstand heavy loads. The flat shape of these bars provides stability and makes installation easy. Moreover, steel flat bars are resistant to bending and warping, ensuring the shelves or brackets remain sturdy and secure. Furthermore, steel can endure various environmental conditions, making it suitable for both indoor and outdoor use. Consequently, steel flat bars are a dependable and pragmatic option for load-bearing shelves or brackets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords