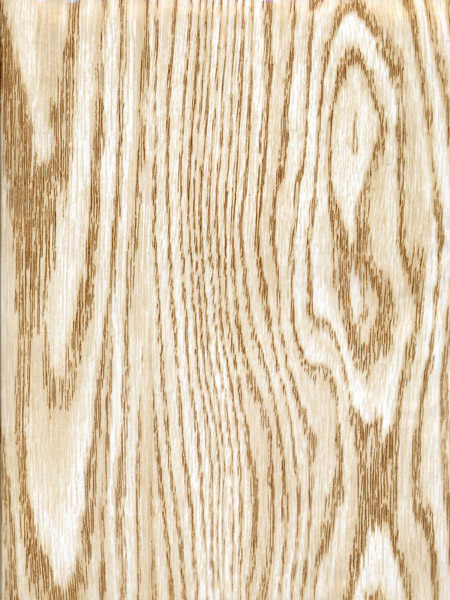

Wtone Pattern Printing Steel Plate-0.55mm*1250mm Z100g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wtone Pattern Printing Steel Plate-0.55mm*1250mm Z100g

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

- Q:How are steel strips used in the production of lighting fixtures?

- Lighting fixtures for various purposes commonly incorporate steel strips. The creation of the fixture's body or housing is one of the primary applications for steel strips in lighting fixture production. To establish the structure of the lighting fixture, steel strips are frequently shaped, bent, or molded into the desired form. This ensures durability, strength, and stability, enabling the fixture to withstand the weight of its components and external forces. Moreover, steel strips can also be employed in the production of brackets or mounting plates, which secure the lighting fixture to the ceiling or wall. These brackets are crucial for proper installation and positioning, guaranteeing the fixture remains securely fixed in place. In certain instances, steel strips can serve as decorative elements in lighting fixture design. They can be fashioned into intricate patterns, curves, or other designs, enhancing the fixture's aesthetic appeal. Furthermore, steel strips may be utilized to manufacture reflectors or diffusers that regulate the direction and intensity of the emitted light. These components are vital for achieving the desired lighting effect and can be customized to meet specific requirements. Overall, steel strips fulfill a vital role in lighting fixture production, providing structural support, decorative elements, and functional components. Ultimately, this contributes to the overall quality and functionality of the product.

- Q:How do steel strips perform in high-stress or high-load applications?

- Steel strips perform exceptionally well in high-stress or high-load applications. Due to their inherent strength, durability, and resistance to deformation, they can withstand heavy loads, maintain structural integrity, and provide reliable performance under extreme conditions.

- Q:How are steel strips used in the production of industrial filters?

- Steel strips are used in the production of industrial filters as a key component for creating the structure and support system of the filter. These strips are typically shaped and welded together to form a sturdy frame that holds the filter media in place and ensures proper filtration efficiency. Additionally, steel strips may also be used in the construction of other components such as brackets or fasteners to secure the filter elements securely.

- Q:Are steel strips used in the production of automotive exhaust systems?

- Yes, steel strips are commonly used in the production of automotive exhaust systems. Steel strips, also known as steel coils, are often used to manufacture the pipes, tubes, and components that make up the exhaust system. These strips offer excellent strength, durability, and heat resistance, making them suitable for withstanding the high temperatures and corrosive gases produced by the engine. Additionally, steel strips can be easily formed, welded, and shaped to meet the specific design requirements of the exhaust system, making them a popular choice in the automotive industry.

- Q:What are the chemical analysis techniques for steel strips?

- Steel strips can undergo various chemical analysis techniques to determine their composition and properties. These techniques encompass: 1. Optical Emission Spectrometry (OES): By exciting the elements within the steel sample through a high-frequency spark, the emitted light is analyzed to ascertain the elemental composition of the steel strip. 2. X-ray Fluorescence (XRF): Employing non-destructive methods, XRF involves bombarding the steel strip with X-rays to prompt the emission of characteristic fluorescent X-rays from the steel's atoms. These emitted X-rays can then be measured to determine the elemental composition. 3. Inductively Coupled Plasma Spectrometry (ICP): ICP involves ionizing the steel sample's elements using high-energy plasma, followed by detection and quantification of the ionized elements using a mass spectrometer. This allows for precise determination of the elemental composition. 4. Atomic Absorption Spectrometry (AAS): AAS entails measuring the absorption of light by specific atoms within the steel strip. By comparing the absorption of light at particular wavelengths to calibration standards, the concentration of elements can be determined. 5. Carbon and Sulfur Analysis: Analyzing carbon and sulfur content is crucial for steel strips. Combustion techniques such as LECO or combustion-infrared methods involve burning the steel strip and measuring the gases released to determine the carbon and sulfur content. 6. Differential Scanning Calorimetry (DSC): DSC analyzes the thermal properties of steel strips. By measuring the heat flow into or out of the steel strip as temperature changes, valuable information about phase transitions, purity, and thermal stability can be obtained. These examples represent only a fraction of the chemical analysis techniques commonly employed for steel strips. The choice of technique depends on the specific analysis requirements, objectives, and the availability of equipment and expertise.

- Q:How are steel strips used in the production of electrical transformers?

- Steel strips are used in the production of electrical transformers as a core material. They provide a low reluctance path for the magnetic flux generated by the transformer, allowing for efficient transfer of electrical energy. The strips are laminated to reduce eddy current losses and improve magnetic properties, resulting in a more reliable and efficient transformer.

- Q:What are the different edge finishes for steel strips?

- Some common edge finishes for steel strips include mill edge, slit edge, deburred edge, rounded edge, and sheared edge.

- Q:Are steel strips resistant to chemicals or acids?

- Yes, steel strips are generally resistant to chemicals and acids, but their resistance can vary depending on the type of steel and the specific chemical or acid involved.

- Q:What is the difference between strip and coil?

- The strip and the coil is the main raw material for the production of welded steel pipe, the steel pipe manufacturing is mainly manufacturing process for spiral welded pipe used for steel roll uncoiling, leveling, trimming, molding, welding, welded pipe must be used for sheet forming and welding, if the steel roll uncoiling leveling must also be cut into leaflets the use of steel plate.

- Q:What are the testing methods used to ensure the quality of steel strips?

- There are several testing methods used to ensure the quality of steel strips. These methods help to ensure that the steel strips meet the required specifications and possess the desired properties. Some of the commonly used testing methods include: 1. Chemical Composition Analysis: This method involves analyzing the chemical composition of the steel strips to ensure that they contain the desired elements in the required proportions. It helps to determine the presence of any impurities or elements that may affect the quality of the steel strips. 2. Mechanical Testing: Mechanical testing involves subjecting the steel strips to various mechanical forces to evaluate their strength, hardness, toughness, and other mechanical properties. Tensile tests, hardness tests, impact tests, and fatigue tests are some examples of mechanical tests used to assess the quality of steel strips. 3. Dimensional Inspection: This method involves measuring the dimensions of the steel strips to ensure that they meet the specified tolerances and dimensions. It helps to identify any deviations from the required dimensions, which may affect the performance and suitability of the steel strips for their intended applications. 4. Surface Inspection: Surface inspection methods such as visual inspection, dye penetrant testing, and magnetic particle inspection are utilized to detect any surface defects or discontinuities in the steel strips. This helps to ensure that the surface of the strips is free from defects that could compromise their quality or performance. 5. Non-Destructive Testing (NDT): NDT methods such as ultrasonic testing, radiographic testing, and eddy current testing are used to identify internal defects or flaws in the steel strips without causing any damage. These methods help to ensure the structural integrity and quality of the steel strips. 6. Corrosion Testing: Corrosion testing is performed to assess the resistance of steel strips against corrosion. Various techniques like salt spray testing, electrochemical testing, and humidity testing are employed to evaluate the corrosion resistance of the steel strips. By utilizing these testing methods, manufacturers can ensure that the steel strips meet the required quality standards and are suitable for their intended applications. These tests help to identify any potential defects or deviations from the desired properties, enabling corrective actions to be taken to enhance the quality and reliability of the steel strips.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wtone Pattern Printing Steel Plate-0.55mm*1250mm Z100g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords