Label Sleeving Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Label Sleeving Machine for Packaging Industry

1. Product Description:

Sleeve labeling machine applies to food & beverage industries as fruit juice, tea, drink, dairy product spure water consiments,beer and sports drink etc. This bottle labeling machine is suitable for various kinds of bottle types:round bottlle,square bottle,flat bottle etc. Sleeve labeling machine for round bottle not only has a highly precise position for casting label,but also withstand the perfect shape of the bottle after shrinkage.

2. Product Features:

Adjustable cutter head:unquely cyclotron cut-off,double sided cutting edge with a long service life.

Single postioning center guide pillar:a more stable for label delivery. Synchronous bottle divider:a more stable transmission for bottle.

Bottom set of label brush:a more precision for casting label.

3. Product Parameters:

Model | TB-S150 sleeve label shrinking machine |

Capacity | 150bottles/min |

Main Material | SUS304 |

Diameter of Bottle | 28-150mm |

Height of Bottle | 30-280mm |

Lable Material | PVC,PET,OPS |

Applicable Label Thickness | 0.027-0.13mm |

Applicable Label Length | 30-250mm |

Transparent Label Length | ≥5mm |

Applicable Internal Diameter of Tube | 5-10 adjust free |

Voltage | 380V,50/60HZ,3PH |

Power | 1.5KW-2KW |

Machine Dimension | 2100mm*850mm*2000mm |

Weight | 800KG |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

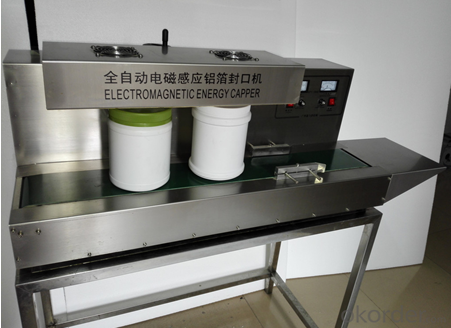

5. Product Pictures:

- Q:What are the main parts of small vacuum machines?

- Aluminum Alloy ordinary aluminum alloy and magnesium alloy, the acid and alkali resistance, corrosion resistance, but the cost is higher, Aluminum Alloy vacuum chamber through a milling processing, the sealing surface and sealing groove is very smooth, the vacuum chamber has good sealing performance. The commonly used stainless steel plate thickness is 2-4MM, thickness of vacuum compression of easy deformation caused by weld cracking, leakage of vacuum chamber, in addition, the general on stainless steel vacuum chamber is provided with a seal groove around the plane, because of the effect of processing, the sealing groove is less smooth, vacuum sealing performance is reduced accordingly. Therefore, some models of vacuum chamber with Aluminum Alloy casting after milling under vacuum sealing groove, chamber adopts thick stainless steel plate processing into plate type, the director, make it short. When purchasing, packaging, and other solid particles relatively dry and non corrosive materials, can be used Aluminum Alloy material, and packaging with soup, salt, acid composition of higher material, can use stainless steel or aluminum magnesium alloy material. The sealing ring is generally made of silicone rubber, black rubber, a few low-grade products using foam rubber, silicone rubber, high temperature resistance, corrosion resistance, good sealing performance, long service life, the foaming rubber sealing is poor, easy to fall off, and short service life. Small treasure vacuum machine

- Q:A workshop to machine parts, 5 boxed 80, according to this calculation, there are 340 parts, 20 boxes can be fully loaded?

- 5 boxes, 80 boxes, =16 20 boxes, only 320 can not be loaded

- Q:Do you have to mark the length of a part in mechanical drawing? I also can be the mechanical cartography, really did not listen to the teacher said to the chief, in the book have not seen this sentence. Just listen to the teacher said, in the assembly plan to mark the total length, height, width. That's for the convenience of packing boxes. For example, I do not want to guarantee a part of its length, but in the middle of each size, I marked the total length is not wrong, and closed ring can also be the length of the ah. Now I work units that must mark the total length, and they compete for profit. I also don't know the basic knowledge of mechanical drawing. I wonder if there is a requirement for this rule

- The total length has no size, it seems that the painting is not standard, the general box has a total length, even if it is not the processing surface, you have to give a total length of nominal size

- Q:Single vacuum packaging machine accessories, vacuum schedule, where to sell?

- Hello, I Division specializing in the production of vacuum packaging machine, vacuum packaging machine accessories, good quality and low price

- Q:Hardware, furniture accessories, packaging machines exported much?

- But if the technology has advantages and the price has advantages, it is still very competitive, and if you can, try to open the international market.

- Q:Can the nylon vacuum packing bag be high and low temperature with mechanical parts?

- The following are the details and features of nylon vacuum packaging bags:1 、 nylon vacuum packing bag, high barrier:The use of different plastic material barrier performance varies greatly, to achieve oxygen, water, carbon dioxide, odor and other high barrier effect.

- Q:What is the definition of machining process specification?

- The machining process is the process of manufacturing or processing parts or parts, using the method of machining

- Q:The true size of a mechanical part is based on what is on the drawing

- The size of the machine parts shall be in accordance with the size of the drawing as specified on the drawings, and be sure to differ from the marked sizes on the package, especially the irregular parts.

- Q:The original card decocting machine liquid packaging regulation failure, how much liquid packaging do not control, do not know which part of a problem, please master answer, thank you.

- If the liquid is not automatically turn off the power, bet, please check the copper into medicine bag (liquid level probe) soiling, connecting wire level probe is loose behind.

- Q:How to package machined parts?

- If need to use rust rust proof paper or paper bag to weather gas bubble bag inside.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Label Sleeving Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords