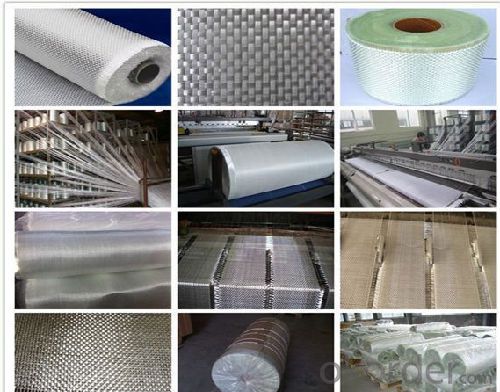

Fiber Woven Fabrics with Best Price Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are

applicable for hand lay-up,

winding and compress molding process, suitable for manufacturing tank, boat, automobile parts

and other FRP products.

Main Features :

Main Features :

Consistent thickness and excellent surface treatment.

Rapid impregnating and good compatibility with resin.

Uniform tension, high dimensional stability and making handing easy.

Good mechanical properties and high strength of parts.

ISO9001 certificated

Woven roving Specification:

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ :

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass mat tissue be used for interior decoration?

- Yes, fiberglass mat tissue can be used for interior decoration. Fiberglass mat tissue is a versatile material that can be used for various purposes, including interior decoration. It is commonly used as a reinforcement material for composite materials, such as fiberglass reinforced plastic (FRP), which can be used to create decorative elements like panels, wall coverings, and moldings. Fiberglass mat tissue is lightweight, durable, and has excellent strength and resistance to moisture and chemicals. It can be easily molded into different shapes and designs, making it a popular choice for interior decoration projects. Additionally, fiberglass mat tissue can be coated or painted to match any desired color or texture, allowing for a wide range of creative possibilities in interior design.

- Q:What is the abrasion resistance of fiberglass mat tissue?

- Fiberglass mat tissue exhibits a relatively high level of abrasion resistance due to its composition. Comprised of finely woven or pressed glass fibers, this material possesses exceptional strength and durability, rendering it highly resistant to abrasion. Consequently, fiberglass mat tissue demonstrates remarkable resilience when exposed to friction or contact with other surfaces, as it remains resistant to wear, tear, or damage. It maintains its structural integrity even under harsh scraping, scratching, or rubbing conditions. As a result, fiberglass mat tissue finds widespread use in various industries, particularly in construction for reinforcing concrete and in composite material manufacturing, where the need for abrasion resistance is paramount.

- Q:Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. It is a common material choice due to its excellent thermal insulation properties and fire resistance. Additionally, fiberglass mat tissue is lightweight, durable, and easy to install, making it suitable for various insulation applications in laboratories.

- Q:What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue differs based on its specific composition and the standards it has been tested against. Typically, fiberglass mat tissue is engineered to possess fire-resistant qualities, but the actual fire rating relies on variables like the tissue's thickness and any supplementary fire retardant coatings or treatments. To ascertain the fire rating of a particular fiberglass mat tissue product, it is advisable to refer to the manufacturer's specifications or test reports, as they offer the most precise and current information available.

- Q:Is fiberglass mat tissue suitable for agricultural applications?

- Certainly! Fiberglass mat tissue proves to be a suitable option for agricultural uses. Its versatility makes it an ideal material in the agricultural sector, providing numerous advantages. The resistance of fiberglass mat tissue to moisture, chemicals, and UV radiation makes it perfect for applications like greenhouse roofing, animal enclosures, and agricultural equipment. It possesses exceptional insulation properties, aiding in the regulation of temperature and safeguarding crops or livestock against harsh weather conditions. Moreover, fiberglass mat tissue is lightweight, easy to install, and long-lasting, making it an economical choice for agricultural projects. In conclusion, fiberglass mat tissue is a fitting material for a wide range of agricultural applications, ensuring durability, flexibility, and safeguarding for the farming industry.

- Q:Does fiberglass mat tissue require any special tools for installation?

- Yes, fiberglass mat tissue may require some special tools for installation. These tools can include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment such as gloves and goggles to protect the installer from potential hazards. Additionally, some installations may require the use of a heat gun or torch to activate or cure the resin. It is important to read and follow the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used to ensure proper installation and to determine if any special tools are required.

- Q:How is fiberglass mat tissue used in the production of chemical storage tanks?

- Fiberglass mat tissue serves as a reinforcement material in the manufacturing of chemical storage tanks. It is combined with resin to create a composite material that offers strength, durability, and protection against different chemicals. By layering the fiberglass mat tissue within the tank structure, its structural integrity is enhanced, and the risk of leakage is prevented. During the manufacturing process, resin, typically polyester or epoxy, is impregnated into the fiberglass mat tissue to establish a strong bond between the fibers and the matrix. This impregnated mat is then placed on a mold or mandrel and covered with additional layers of resin and mat, resulting in a laminate. The number of layers and thickness can vary based on the desired tank specifications and the chemicals it will store. The combination of fiberglass mat tissue and resin yields outstanding corrosion resistance, making it ideal for storing a wide range of chemicals. Fiberglass is inherently non-reactive and can endure exposure to harsh chemicals, acids, and alkalis without compromising the tank's structural integrity or degrading. Hence, fiberglass mat tissue is the preferred material for chemical storage tanks as it guarantees the safety of stored chemicals and minimizes the risk of leaks or contamination. Moreover, the utilization of fiberglass mat tissue enables the production of tanks with complex shapes and sizes. It can be easily molded and formed into various configurations, providing flexibility in design. This ensures that chemical storage tanks can be tailored to specific requirements and seamlessly integrated into diverse industrial applications. In conclusion, fiberglass mat tissue is indispensable in the manufacturing of chemical storage tanks. It reinforces the tank structure, offers chemical resistance, and facilitates the fabrication of tanks with diverse shapes and sizes. When combined with resin, it creates a durable and corrosion-resistant composite material, ensuring the secure storage of chemicals in a variety of industrial settings.

- Q:Can fiberglass mat tissue be used for insulating refrigeration units?

- Fiberglass mat tissue is indeed suitable for insulating refrigeration units due to its lightweight nature and outstanding thermal insulation properties. It finds extensive use in a wide range of applications where insulation is necessary, including refrigeration units. By minimizing heat transfer, the fiberglass mat tissue ensures that the internal temperature of the refrigeration unit remains stable, safeguarding the stored items from any external heat. Moreover, its moisture-resistant capabilities are particularly crucial in refrigeration units as they prevent condensation and help maintain the cooling system's efficiency. All in all, fiberglass mat tissue proves to be a reliable and effective option for insulating refrigeration units.

- Q:How does the weight of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is significantly affected by its weight. The weight of the tissue indicates the amount of glass fibers per unit area. Generally, a higher weight indicates a greater concentration of fibers, which results in improved strength and durability. To begin with, a heavier fiberglass mat tissue provides better tensile strength. The increased number of fibers in the tissue enables it to withstand higher levels of stress and strain without breaking or tearing. This makes it ideal for applications that require a high load-bearing capacity, such as structural components in the construction or automotive industries. Additionally, the weight of the tissue also impacts its stiffness and rigidity. A heavier mat tissue offers better dimensional stability, meaning it will maintain its shape and form even when subjected to external forces. This is crucial in applications where the material needs to retain its structural integrity, such as in boat hulls or wind turbine blades. Moreover, the weight of the fiberglass mat tissue affects its thermal and acoustic insulation properties. A higher weight is usually associated with better insulation capabilities, as the increased fiber density enhances the material's ability to trap air and reduce heat transfer or sound transmission. This makes it suitable for applications that require effective insulation, such as in buildings or industrial equipment. Finally, the weight of the fiberglass mat tissue can impact how easily it can be handled and installed. A lighter tissue may be more flexible and easier to manipulate, making it simpler to fit into complex shapes or tight spaces. Conversely, a heavier tissue might require additional support or equipment during installation. In conclusion, the weight of fiberglass mat tissue has a direct influence on its performance characteristics, including tensile strength, rigidity, insulation properties, and ease of handling. Therefore, it is crucial to consider the intended application and the desired performance requirements when selecting the appropriate weight of fiberglass mat tissue.

- Q:Is fiberglass mat tissue suitable for automotive interiors?

- Yes, fiberglass mat tissue can be suitable for automotive interiors. Fiberglass mat tissue is a versatile material that is commonly used in various industries, including automotive manufacturing. It offers several benefits that make it suitable for automotive interiors. Firstly, fiberglass mat tissue provides excellent insulation properties. It helps in reducing noise, vibration, and harshness (NVH) levels inside the vehicle cabin. This can significantly enhance the overall comfort and driving experience for passengers. Secondly, fiberglass mat tissue is lightweight and flexible, making it easy to install in different areas of the car interior. It can be molded and shaped to fit various parts, such as door panels, headliners, trunk liners, and floor carpets. Its flexibility also allows for easy integration with other components, such as sound-deadening materials, to further improve insulation and reduce vibrations. Additionally, fiberglass mat tissue is resistant to heat, moisture, and chemicals, which are often present in automotive environments. This makes it a durable and long-lasting material that can withstand the unique conditions inside a vehicle. It is also resistant to mold and mildew growth, ensuring a clean and hygienic interior. Furthermore, fiberglass mat tissue can be easily coated or laminated with other materials to enhance its aesthetic appeal. It can be finished with various fabrics, vinyl, or leather to match the desired interior design and provide a luxurious feel. In summary, fiberglass mat tissue is a suitable material for automotive interiors due to its insulation properties, lightweight and flexible nature, durability, resistance to heat and moisture, and potential for aesthetic enhancements. Its usage can contribute to creating a comfortable, quiet, and visually appealing cabin space for vehicle occupants.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Woven Fabrics with Best Price Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords