BNBM PUM Two-component Polyurethane Waterproof Coating

- Supplier:

BNBM Waterproof Co., Ltd

BNBM Waterproof Co., Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

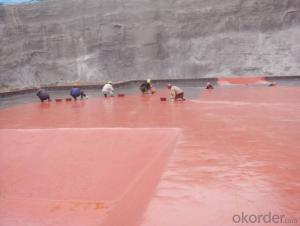

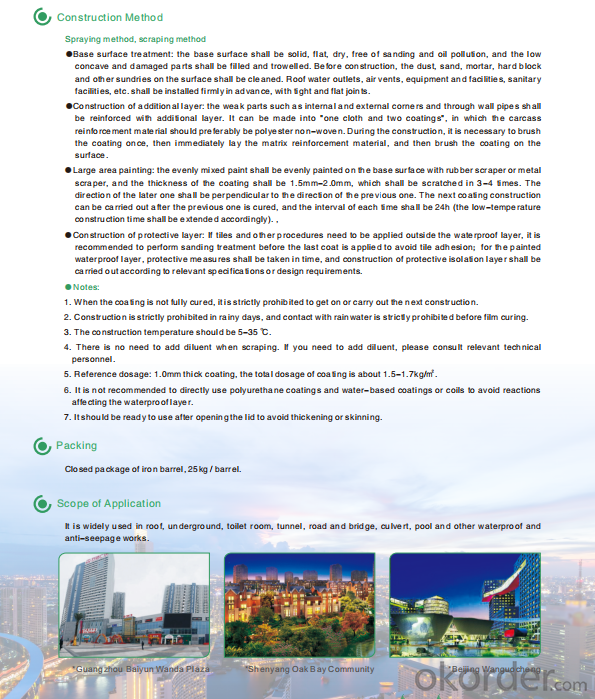

The two-component polyurethane waterproof coating is a film formed by reaction and solidification of two omponents A and B. Component A is a transparent to light yellow viscous liquid containing isocyanate end group generated by polymerization of polyether, polyisocyanate and other raw materials; Component B is a paste formed by mixing and processing of cross-linking agent, accelerator, toughener, tackifier, mould inhibitor, filler and pigment. When in use, A and B components are mixed in a certain proportion, stirred evenly, scraped and coated on the base surface, and after several hours of reaction curing, a waterproof coating with elasticity, toughness and durability is formed.

- Q: What is the price of a waterproof window cover?

- 1, solid wood sets With the emphasis on environmental protection and economic conditions, some families choose solid window curtains, solid wood materials with environmental protection, beautiful, natural and other advantages, but also easy to deformation, thermal expansion and contraction, crack and other shortcomings. According to the final color of different, solid wood sets are divided into primary colors, color and color mixing. At present, more often solid wood materials are Pinus sylvestris, red pine, Qu Liu, Catalpa wood, and some valuable materials such as: beech, Phoebe, pear, rosewood and so on.

- Q: What material waterproofing can be mixed with cement sand

- Construction can be made with the waterproofing agent and cement made of waterproof mortar. The ratio of cement to sand is 2: 3, and the amount of waterproofing agent is 1% of the cement.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Of course harmful, not just this particle, there are auxiliary materials are also toxic.

- Q: Oriental rain rain waterproof how to

- Originally only a few hundred hours, they have done 3,000 hours of anti-aging test, until each test are qualified to the market. So the East Rainbow waterproof coating is absolutely trustworthy waterproof material brand.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: Nanning building waterproof material market where

- to buy what materials are going to go to some factories, such as paper, printing materials and other manufacturers in the Nanning High-tech Zone or Nanning Economic Development Zone may be more

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Construction of roof waterproofing membrane First, the process (hot melt construction) Clean up the grass-roots → brushing the primary treatment agent → paving the film additional layer → paving the film → hot melt sealing side → water test → protective layer

- Q: FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q: Waterproof material water leakage construction should pay attention to what

- 3, do the closed water test After the waterproof construction is completed, the water storage test. Will be blocked all the toilet outlet, the door at a pound of about 200mm high barrier, and then poured in the bathroom about 20mm ~ 30mm deep water, and 24 hours after the inspection of the walls and the ground around the leakage phenomenon , Waterproof test is to ensure the quality of the bathroom waterproofing the key, we must do. Such as after 24 hours without leakage as qualified. If you find a leak, you should immediately stop the water storage test, re-waterproof layer to improve the treatment, after passing the water test.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar and cement mortar difference: Cement mortar is the synthesis of three main materials, cement, sand and water, and mixed mortar is the synthesis of four major materials, cement, sand, lime and water.

Send your message to us

BNBM PUM Two-component Polyurethane Waterproof Coating

- Supplier:

BNBM Waterproof Co., Ltd

BNBM Waterproof Co., Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches