Naue Geogrids Black PP Geogrid for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

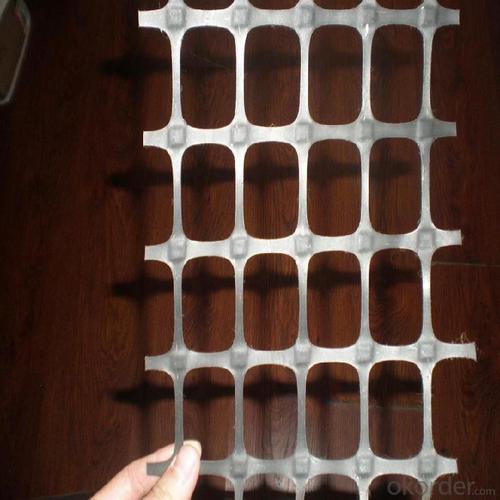

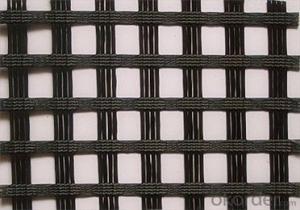

Structure of Black PP Geogrid

Black PP Geogrid is High tensile strength at both longitudinal and transverse direction,

Soft foundation reinforcing for hightway,railway, slope protecting projects, landfill sites

Main Features of the Black PP Geogrid

fiberglass geogrids

Corrosion resistance, no long-term creep, long life span.

Good physical and chemical stability and good thermal stability.

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Black PP Geogrid Images

Black PP Geogrid Specification

Roadbed reinforcement of road and railway,crack prevention,increase of roadbed strength;

Reinforcement and stabilization of riverside,embankment and side slope;

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

- Reinforcement of soft soil foundation and overall strength of roadbed

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Biaxial Plastic Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Polyester warp knitted polyester coating is PVC glue, glass fiber geogrid is that sensitive asphalt rubber. An anti-corrosion, a alkali resistance. Material is not the same, the appearance is not difficult to distinguish between experts

- Q: The difference between polyester glass fiber cloth and glass geogrid

- Hello, this is two different products

- Q: Is the test items within the inspection listAcceptance specification

- Overlapping width of Geogrid

- Q: How to choose 15kn bidirectional geogrid geogrid

- Two, the geogrid in the purchase price and the quality of geogrid, in addition to clear geogrid types and geogrid specifications, but also pay attention to the price of Geogrid and geogrid quality, the problem is most concerned with the purchaser

- Q: Are geogrids effective in erosion control?

- Yes, geogrids are effective in erosion control. They provide stability and reinforcement to soil, preventing erosion by holding the soil in place and reducing the movement of sediments. Geogrids also improve the load-bearing capacity of the soil, making them suitable for various erosion control applications such as retaining walls, slopes, and embankments.

- Q: What is the lifespan of a geogrid?

- The lifespan of a geogrid can vary depending on factors such as the quality of the material, environmental conditions, and the level of stress it experiences. However, with proper installation and maintenance, geogrids can typically have a lifespan of 20 to 50 years.

- Q: Are geogrids effective in preventing soil erosion around pipelines?

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids are engineered materials that provide reinforcement and stabilization to the surrounding soil. They create a barrier that helps prevent soil movement and erosion caused by water flow or other environmental factors. Geogrids also distribute the weight and stress of the pipeline more evenly, reducing the chance of soil settlement and potential damage. Overall, geogrids play a crucial role in protecting pipelines from soil erosion and ensuring their long-term stability.

- Q: Can geogrids be used in reinforcement of soft soils?

- Yes, geogrids can be used in the reinforcement of soft soils. Geogrids are commonly used to improve the stability and strength of weak or soft soils by distributing the load more evenly and reducing settlement. They are effective in providing reinforcement and preventing soil deformation, making them a suitable solution for reinforcing soft soils.

- Q: Are geogrids resistant to chemical exposure?

- Yes, geogrids are generally resistant to chemical exposure. They are designed to withstand various environmental conditions, including exposure to chemicals, without significant degradation or loss of performance. However, the specific level of chemical resistance may vary depending on the type and composition of the geogrid material.

- Q: Geogrid construction must be folded back 2m wrapped in compacted packing

- Paved geogrid, laying artificial upper filler, finish rolling in a timely manner, to avoid long-term exposure, and then the mechanical transport, leveling, compaction machinery, paving and rolling forward from both sides to the middle, rolling from both sides to the middle, the degree of compaction keep meet the specification

Send your message to us

Naue Geogrids Black PP Geogrid for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords