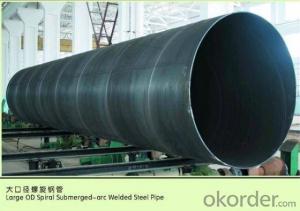

BG ssaw steel pipe with material x56 x70,large diameter sprial welded pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | ERW Pipe / Welded Pipe / Black Pipe/LSAW | |

Size | OD | 406-1522.4mm(16-56in) |

Thinkness | 8-50mm(apply to simple carbon steel,low carbon alloy steel);6.4-26.4mm(apply to X70 and above) | |

Length | 3-12.5m or as required | |

Steel Material | Gr.B,X42-X70 PSL1, X42-X80 PSL2, L245-L555NB,A516Gr, 55-70 CL11-32 | |

Standard | APISpec5L, APISpec2B, ISO383, GB/T9711-2001,ASTMA671,ASTMA672,JIS DIN, | |

Usage | Natural gas, petroleum, chemical industry, electric power, metallurgy thermodynamic fields, water supply engineering, steam heating, hydroelectric power station and long pipeline transportation projects and so on. | |

Ends | Usually Plain ,But Can Be Beveled Or By Your Choice | |

Technique | LSAW | |

Surface | Bared Or Black Painted, Galvanized Or With Oiled Or as Client Required | |

Type | Welded | |

Section Shape | Round | |

Third Party Inspection | SGS,BV,CE | |

Inspection | 100% ultrasonic flaw detection for the material plate;100% automatic on-line UT test after welding; 100% whole-length seam X-ray test; 100% inside weld line industrial TV test; 100% hydrostatic test; 100% automatic on-line seam UT test after hydrostatic test, expanding; 100% X-ray test and make X-ray film or picture record on pipe ends; 100% pipe appearance and plate appearance inspection. | |

Package | In square bundles with standard seaworthy export packing or as request | |

Date of Delivery | 5-45days according to the QTY | |

Supply Ability | 150000tons/year | |

Port of Shipment | Tianjin Port | |

Payment term | T/T, Irrevocable L/C at sight | |

Trade Term | FOB CFR CIF | |

Others | 1) Contract Manufacturing: OEM Service Offered, Design Service Offered, Buyer Label Offered 2) Small quantity can be acceptable 3) Non-standard products can be ordered 4) A strong production capacity and a large inventory guarantee the quick delivery | |

- Q: How do you inspect steel pipes for defects?

- The inspection of steel pipes for defects requires a methodical approach that combines visual examination, non-destructive testing (NDT) techniques, and specialized equipment. The following are the typical steps undertaken to inspect steel pipes for defects: 1. Visual Examination: Commence by visually inspecting the external surface of the pipe, searching for any visible indications of defects, including cracks, dents, or corrosion. Particular attention should be given to welds, joints, and areas prone to stress or damage. 2. Ultrasonic Testing (UT): Ultrasonic testing is commonly employed to identify internal defects in steel pipes. This technique involves transmitting ultrasonic waves into the pipe and then interpreting the echoes received. Any irregularities in the internal structure, such as cracks or voids, can be identified and analyzed. 3. Magnetic Particle Inspection (MPI): MPI is a widely utilized technique for detecting defects on or near the surface, such as cracks, seams, or other discontinuities. This method involves applying a magnetic field to the pipe and subsequently applying ferromagnetic particles (usually iron-based) to the surface. These particles accumulate and form visible indications at areas where magnetic flux leakage is caused by defects. 4. Eddy Current Testing (ECT): Eddy current testing is suitable for detecting surface and near-surface defects in conductive materials like steel. This technique involves inducing an alternating current into the pipe and monitoring changes in the electrical currents induced by any present defects. These changes are then analyzed to identify and evaluate the defects. 5. Radiographic Testing (RT): Radiographic testing is conducted by exposing the steel pipe to X-rays or gamma rays and capturing radiographic images of the pipe. This technique allows for the detection of internal defects, such as cracks, porosity, inclusions, or variations in wall thickness. The radiographic images are subsequently examined for any indications of defects. 6. Dye Penetrant Inspection (DPI): DPI is a method used to identify defects on the surface of steel pipes. It involves applying a liquid dye to the surface, which penetrates into any surface cracks or flaws. After sufficient time for the dye to seep in and react, excess dye is removed, and a developer is applied to draw out the dye from the defects, rendering them visible. 7. Pressure Testing: Pressure testing entails pressurizing the steel pipe to a predetermined level and monitoring for any pressure drops or leaks. This test ensures that the pipe can withstand the required pressure without any structural defects. It is worth noting that the choice of inspection technique depends on various factors, such as the type of defect being sought, the size and characteristics of the pipe, and the specific industry standards and regulations. Inspection professionals with expertise in NDT methods and equipment are typically employed to ensure precise and dependable results.

- Q: How are steel pipes used in the manufacturing of heat exchangers?

- Steel pipes are commonly used in the manufacturing of heat exchangers due to their strength, durability, and ability to withstand high temperatures and pressures. These pipes are typically used to create the primary heat transfer surfaces within the heat exchanger, allowing for efficient transfer of heat between two fluids. The steel pipes are often arranged in a coil or tube bundle configuration, providing a large surface area for heat exchange to occur. Additionally, the corrosion-resistant properties of steel make it an ideal choice for handling various fluids in heat exchanger applications.

- Q: How are steel pipes recycled?

- Steel pipes are recycled through a multi-step process that involves collection, sorting, cleaning, and melting. First, the used steel pipes are gathered from various sources such as construction sites or industrial facilities. Then, they are sorted based on their size, shape, and quality. Next, any contaminants or coatings are removed from the pipes through cleaning and stripping processes. Finally, the cleaned pipes are melted down in a furnace, and the molten steel is formed into new pipes or other steel products. This recycling process reduces the demand for new raw materials and helps conserve energy and resources.

- Q: Can steel pipes be used in extreme weather conditions?

- Yes, steel pipes can be used in extreme weather conditions. Steel is a durable and strong material that can withstand various weather conditions, including extreme temperatures, high humidity, and severe storms. Additionally, steel pipes can be coated or treated to provide additional resistance against corrosion, making them suitable for use in harsh environments.

- Q: How are steel pipes used in the manufacturing of chemical processing plants?

- Steel pipes are commonly used in chemical processing plants for various purposes, such as transporting fluids and gases, as well as providing structural support. They are highly resistant to corrosion, making them ideal for handling corrosive materials in the plant. Additionally, steel pipes can withstand high temperatures and pressure, ensuring the safe and efficient operation of chemical processes.

- Q: How can galvanized steel tubes be painted on the surface?

- Galvanized parts are nonferrous metals, ferrous metals are black, all metal adhesion is poor;

- Q: Can steel pipes be used for transporting slurry?

- Yes, steel pipes can be used for transporting slurry. Steel pipes are commonly used in various industries, including mining, construction, and oil and gas, for transporting different types of fluids, including slurry. Slurry is a mixture of solid particles suspended in a liquid, usually water, and steel pipes have the required strength and durability to handle the abrasive nature of slurry. Additionally, steel pipes have excellent resistance to corrosion, which is crucial when dealing with slurry that may contain corrosive elements. The smooth inner surface of steel pipes also helps to minimize friction and ensure efficient flow of the slurry. Overall, steel pipes are a reliable and commonly used choice for transporting slurry due to their strength, durability, corrosion resistance, and smooth inner surface.

- Q: How are steel pipes used in nuclear power plants?

- Steel pipes are extensively used in nuclear power plants for various purposes. They are primarily used for the transportation of coolant, such as water or gas, which helps in removing heat from the reactor core. Steel pipes are also used to convey steam generated by the reactor to the turbine, where it is used to generate electricity. Additionally, steel pipes are utilized for the transportation of various fluids, such as lubricants and chemicals, for different processes within the plant. The durability, strength, and resistance to high temperatures and pressure make steel pipes an ideal choice for these critical applications in nuclear power plants.

- Q: What are the common defects found in steel pipes?

- Some common defects found in steel pipes include corrosion, cracks, pitting, scaling, and distortion.

- Q: What are the future trends in steel pipe manufacturing?

- Some future trends in steel pipe manufacturing include the adoption of advanced technologies such as automation and robotics, the development of high-performance and sustainable materials, the implementation of efficient and eco-friendly production processes, and the integration of digitalization and data analytics for improved quality control and supply chain management. Additionally, there is a growing focus on the development of specialized pipes for specific industries such as oil and gas, construction, and automotive, as well as an increased emphasis on product customization and tailored solutions to meet the evolving needs of customers.

Send your message to us

BG ssaw steel pipe with material x56 x70,large diameter sprial welded pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords