Basalt Roving for Chop High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

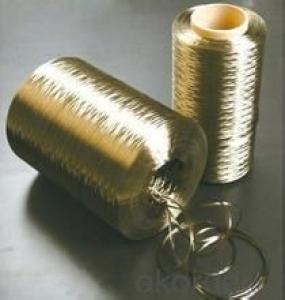

Description of Basalt Fiber Roving

Basalt fiber roving is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase,

pyroxene, and olivine. It is similar to carbon fiber and fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber. It is used as a fireproof textile in the aerospace and automotive industries, and can also be used as a composite to produce products such as camera tripods.

Specifcation of Basalt fiber roving:

Filament diameter | Linear density | Sizing type | Agent content | Moisture content |

9 | 130 | Silane | ≤0.8 | <0.1 |

11 | 400 | Silane | ≤0.8 | <0.1 |

13 | 800 | Silane | ≤0.8 | <0.1 |

13 | 2400 | Silane | ≤0.8 | <0.1 |

13 | 1200 | Silane | ≤0.8 | <0.1 |

Field of application:

1. Winding tube, tank, cylinder

2. Weaving plaids, mesh cloth, geotextile

3. Repair and reinforcement for Building structure

4. as substrate materials of hihg temperature resistant chopped fiber thermoplastic composite of sheet molding compound (SMC, BMC), bulk molding compound (DMC)

5. Suitable for high-strength, high temperature winding, woven roving, pultrusion, injection molding, is as substrates to produce a variety of composite materials, but also as reinforcing material for the production of high-strength, SMC resistance

Packaging & Delivery

| Packaging Detail: | standard export package or as customer's requirements for 2400tex basalt roving |

| Delivery Detail: | Three to Five weeks |

- Q: The characteristics and application of KH560

- Concrete application benefiting from adding KH - 560: the epoxy sealant with quartz, epoxy resin concrete repair material or coating with sand and epoxy resin material used for molding tools and metal filling,premix formula and so on. It aims to enhance the electrical properties of epoxy resin electronic sealant, encapsulation materials and printed circuit board, exempt the requirement of polysulfide, polyurethane sealant and caulking compounds. It benefits from specific application of the addition of KH-560. After the adjustment period. Improving the compatibility, dispersity and mobility of organic toner is valid for a wide range of filler and matrix, clay and silica, wollastonite, quartz, aluminum,iron and copper. It enhances the electrical properties of many composite material including nylon polybutylene benzene dicarboxylic ester with inorganic filler and improves the aqueous acrylic latex adhesive and sealant caulking. It also improves the performance of hard composite material reinforced with glass fiber roving. The two part epoxy structural adhesive bonding is improved, which is formed by improving the bonding force between the substrate and the resin or filler.

- Q: How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q: Is glass steel a glass?

- Ordinary steel is only a combination of iron and carbon, while the composition of FRP is complicated. Toughened glass is stronger than ordinary glass. One advantage is strong, and the two is broken, will not produce the tip of the debris, so that people are relatively safe.

- Q: Introduction of inorganic glass fiber reinforced plastic air pipe

- Inorganic glass fiber reinforced plastic air pipe, according to the properties of the binding materials, can be divides into: Made of binding materials with glass fiber mesh cloth hydraulicity inorganic glass steel duct and made of cementitious materials and glass fiber mesh air hardening modified magnesium oxychloride cement duct with two types of modified magnesium oxychloride cement to the sulfate type. The pH value of the hardened material should be less than 8.8, and there is no alkalinity corrosion of the glass fiber. Inorganic glass steel duct should be used alkali-free, medium alkali or alkali resistant glass fiber mesh cloth, and are consistent with current national standard "glass fiber grid" JC561, "the alkali free glass fiber roving," JC/T281, "in the alkali glass fiber roving" JC/T576 regulations. The quality of magnesium oxychloride cement duct Magnesium Oxide should comply with the national standard "Magnesium Oxide" light burned magnesite products with WB/T1019-2002 regulations. Inorganic glass steel duct can divided into the overall common type (non insulation), integral insulation type (inner and outer surface of inorganic glass steel, middle insulating material) and combination type (by special adhesive, composite plate, flange, reinforcement angle etc) and the combination of insulation, its production parameters should comply with the provisions of the table 1, 2, 3. The longitudinal and transverse lap joint distance between adjacent layers of glass fiber grid cloth should be more than 300mm, and the distance of the same layer lap joint shall not be less than 500mm. Lap length should be greater than 50mm. The wind pipe surface thickness of the slurry flating glass fiber mesh cloth is appropriate. And the surface do not have dense pores and spillage.

- Q: What does fireproof bag used for ?

- The outer layer is made of glass fiber twistless roving and its inner layer is filled with special refractory, thermal insulation and expanding materials, which can expand in high temperature and solidified so as to form a sealing layer for the purpose of preventing fire spreading.

- Q: All about bamboo fiber.

- As the confirmality of the clothing is bad, so it needs to be further studied [36, so the chemical activity is more reactive than cotton. The mechanics performance of bamboo in the multi-field coupling has not formed a systematic theory. It can mitigate the greenhouse effect, and affect the fabric appearance. Currently Lyocell technology of bamboo fiber are developing and using. Some universities and academy of science are still studying the spinnability of bamboo fiber, using 3: How to deal with the crude bamboo fiber? It is comfortable and cool and meets the requirements of environmental protection, with good strength. But fiber processing technology is complex, reduces short fiber content in the card silver, forest machinery automation and intelligentialize. The bamboo fiber is divided into two categories. The method of fabric finish tectile dressing is better.

- Q: What resin fiber powder can be used for?

- 扔掉

- Q: What can glass fiber do?

- Glass is kniwn for a brittle material . Interestingly, once the glass is heated after being drawn into a much thinner than a human hair fiber glass, it seems it completely changes their own nature, being soft like synthetic fiber, being tougher than the same thickness of the stainless steel wire.Then what does it used for? It could be made into glass rope.

- Q: Does glass wool belongs to glass fiber cloth?

- No, glass wool belongs to the one category of glass fiber and it is a kind of artificial inorganic fiber. Glass fiber cloth is twistless roving plain fabric made by glass fiber cloth.

Send your message to us

Basalt Roving for Chop High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords