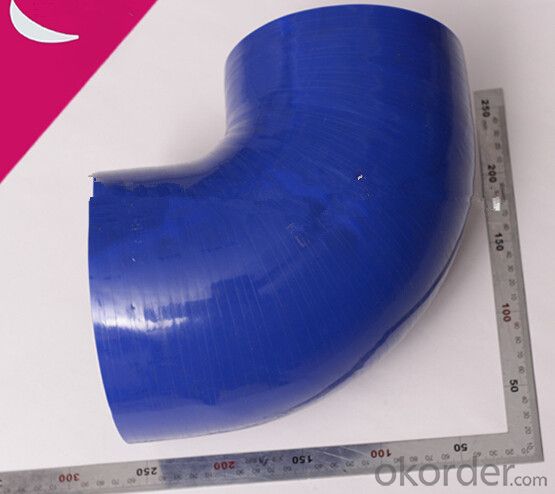

Automobile 90 Degree Elbow Coupler Silicone Hose OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Hose

Specifications

flexible high temperature silicone hose

1.factory price

2.ISO 9001

3.big productivity

4.good aftersales service

Products ID/mm

ID/inch

straight hose 6mm-152mm 0.235''-6''

1 meter silicone hose 6mm-152mm 0.235''-6''

2 meter silicone hose 10mm-76mm 0.4''-3''

straight reducer 25mm-152mm 1''-6''

45 degree/ 45 degree reducer silicone hose 19mm-152mm 0.75''-6''

90 degree/ 90 degree reducer silicone hose 8mm-152mm 0.315''-6''

135 degree silicone hose 38mm-102mm 1.5''-4''

180 degree/U shaped silicone hose 25mm-102mm 1''-4''

Product | silicone hose |

Working Temperature | -60-260 degree |

Working Pressure | 0.3 to 0.9 Mpa |

Bursting Pressure | 2Mpa |

Hose Thickness | 2mm to 6mm |

Hose Reinforcement | 1-5ply |

Size Tolerance | +/- 0.5mm |

Color Option | Blue/Red/Black/Orange or customized |

SHAPE | APPLICATION |

Straight meter hose | Radiator/Coolant connection Hose |

Straight coupler hose | Water connection Hose |

45°/60°/90°/135°Elbow hose | Vented Hose |

Reduction hose | Turbocharger connection Hose |

Hump hose | Air Intake connection Hose |

T hose | Intercooler connection Hose |

U hose | Fluorosilicone Hose |

TIPS | |

Custom products according to customers’drawing or samples. | |

Used for VOLVO,BENZ,BMW,TOYOTA,MAZDA,SCAIA,IVECO,AUDI,DAF,truck | |

Print your LOGO on the products | |

universal product!perfect for turbo,intercooler,intake,turbo charger projects ! | |

Application forTruck,Bus,Tuningcar,Racing car,Heavy Machine,Engineering.Vessel | |

Used for Automotive turbo charge,coolant,Air inlet/exhaust,Radiator,Heater system | |

Made for high remperature and high boost applications. | |

- Q: Where does the car use the most rubber parts?

- The most used rubber on the car must be the tires. The second is the rubber pad at the joint, as well as the rubber sleeve for the movable joint and the rubber seal for sealing. Apart from tires, the rest of the world is the most difficult to use because of the different models.

- Q: There is a layer of net in the rubber of the automobile tire, what material is the metal net or what other material?

- The truck tyres are usually made of bias tyres, and they are also made from fixed angles

- Q: Are all the rubber made from petroleum?

- Synthetic rubber is the process of refining and polymerizing monomers from petrochemical products, which is best processed. Many properties of synthetic rubber are not available in natural rubber, such as oil resistance, acid and alkali resistance

- Q: What are the rubber parts for the car?

- There are many, such as tires, car wipers, brake pads, gaskets for high temperature parts such as engines, and air springs (for shock absorption)

- Q: What's the rubber tube on the empty filter for the motorcycle?

- Some air filters also have rubber inlets for the purpose of ensuring that the air near the inlet is clean.

- Q: What glue does the ceiling fabric fall off inside the car?

- Polyurethane glue is the molecular chain containing ammonia ester and isocyanate glue, due to the presence of strong polar isocyanate and carbamate radicals, highly reactive, can be cured at room temperature, which has excellent adhesive properties to metals, rubber, glass, ceramics, plastics, wood, fabric, leather a variety of materials such as.

- Q: How are the car tyres made?

- The car the whole tire is not too humble, but tire for vehicles, like shoes for people, its importance is absolutely not. We understand the tire production process, help to enhance your Goodyear brand trust. Process 1: dense process, refining process is to carbon black, natural / synthetic rubber, oil, additives, accelerators and other raw materials mixed together, in the mixer for processing, the production of "glue" process. All raw materials must be tested before entering the mixer and can be used after being released. The weight of each mixer is about 250 kilograms. Each rubber component used in the tire is of a specific property. The composition of the rubber depends on the performance requirements of the tire. At the same time, the change of the composition of the rubber depends on the needs of the manufacturers and the market. These requirements mainly come from traction, driving performance, road conditions and the requirements of the tires themselves.

- Q: What is the difference between asphalt damping sheet and butyl rubber?

- In Europe and the United States and other developed countries in the automotive industry, automobile damping film is generally used high polymer resin material, or rubber material. As raw materials, these two raw materials will not volatilize toxic and harmful gases. In China, there is a damping film made of asphalt,Continuous dissemination of odor, leading to air pollution in the car, endangering human health.

- Q: Please help to understand what parts of the car are used rubber parts, must be more specific Oh!

- This problem is more complex, generally need shock absorption and sealing place to use.

- Q: Ding Ji rubber and nitrile rubber difference

- Nitrile butadiene rubber is prepared by polymerization of butadiene and acrylonitrile by emulsion polymerization. Nitrile rubber is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesive force. Its disadvantages are poor resistance to low temperature, poor ozone resistance, poor electrical properties, and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil resistant rubber products.

Send your message to us

Automobile 90 Degree Elbow Coupler Silicone Hose OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords