Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Automatic Auger Filling Machine

This Machine is a complete, economical solution to your filling production line requirements.can measuring and filling powder and granular. It consists of the Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).it fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

2. Features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Quick disconnecting hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3. Technical parameters

First type-Liner type

| Model | TP-PF-A21 | TP-PF-A22 |

| Control system | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 25L | Quick disconnecting hopper 50L |

| Packing Weight | 10 - 5000g | 10 - 5000g |

| Dosing mode | Directly dosing by auger | Directly dosing by auger |

| Paching accuracy | ≤500g, ≤±1%; >500g,≤±0.5% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 15 - 40 times per minute | 15 - 50 times per minute |

| Air supply | 6 kg/cm² 0.05m³/minute | 6 kg/cm² 0.05m³/minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.6 KW | 1.6 KW |

| Total weight | 300 kg | 300kg |

| Overall Dimensions | 2000*970*2030mm | 2000*970*2300mm |

Second type- Rotary type

| Model | TP-PF-A301 | TP-PF-A302 |

| Hopper volume | 25L | 50L |

| Container size | φ20-100mm; H15-150mm | φ30-160mm; H50-260mm |

| Control system | PLC & Touch screen | PLC & Touch screen |

| Packing weight | 1 - 500g | 10 - 5000g |

| Packing accuracy | ≤100g, ≤±2%; 100-500g,≤±1% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 20-50 bottles per minute | 20-40 bottles per minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.2 KW | 2.3KW |

| Air supply | 6kg/cm² 0.05m³/minute | 6kg/cm² 0.05m³/minute |

| Total weight | 160kg | 260kg |

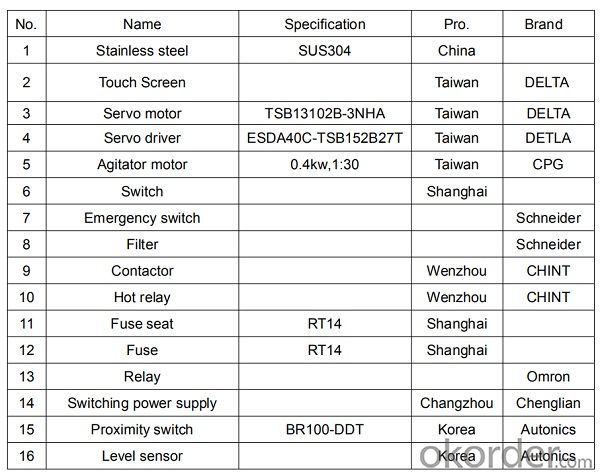

4. Configuration list

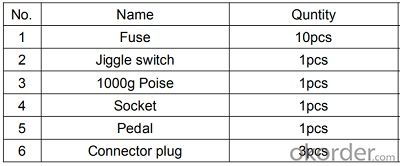

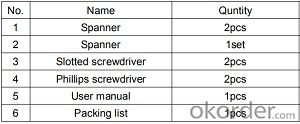

Accessories

Accessories tools

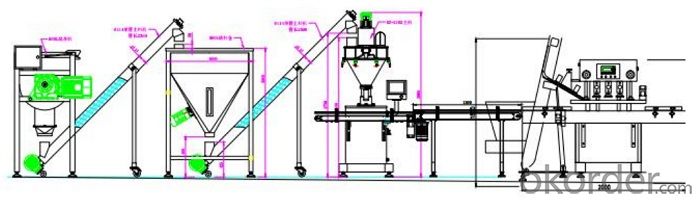

5. Image of fonction

6. Remark

- Delivery Period: 25 days after receipt of down payment

- Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery.

- Guarantee Period: 12 months

- Package: seaworthy plywood carton

- Q: What is the transport theory in logistics management?

- Moving company handling the design scheme, main is according to the material classification, distribution and move route, selecting the appropriate combination between handling equipment, equipment and method of use. The active theory of handling and handling can improve the loading and unloading plan, which makes the design of the scheme and the choice of the equipment quantitatively. It also forms an effective method for checking and comparing schemes. Application of the theory of activity, and other conditions and influences, can be achieved.

- Q: The stability of material lift machine mainly depends on which parts of the material hoist

- The stability of material lift machine mainly depends on the material elevator's foundation, the wall rack, the line and the anchor. (1) the foundation of the basic elevator is designed and constructed according to its type and soil quality, so that it can withstand the full load on it. (2) the steel structure between the frame of the frame and the structure of the building is called the attached wall frame. Rigid connections should be adopted and stable structures are formed.

- Q: Ask for material handling robot design report

- Now on the college students of the experiment, you block him, at the gate of the laboratory to borrowed his experiment teaching material, were asked about the content of this course, as long as it is accurate, detailed, they not answer, he was dazed, asked the teacher is also a gaping; If he were to make the lab equipment, it would be eight, dead and dead. Now the school teaching equipment is procured from the society, the original manuscript of the experimental handout is provided by the teaching instrument supplier, the other can be imagined. To graduate, is the original abroad under the guidance of scientific literature and database import software systems, hardware platform, market procurement module and application-specific integrated circuit and components of the system integration, fast food science and technology, modern technology large platter

- Q: How do you query the serial number of each part of the lenovo notebook

- The packing list contains the material number Or common sense to the lenovo website, you need to provide a host number.

- Q: The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- Material hoist hanging scaffold platform (also called construction lifter lifting cage) and unloading platform construction scaffolding each floor of the mouth or platform, in order to ensure safety construction, two platform where the horizontal spacing should be not greater than 50 mm.

- Q: The parameters of the powder materials transport vehicle

- The production capacity of the semi-suspended tank in the transport of the three-axis powder material is 45 to 60 cubic meters. CLW5315GFLT3 type powder material truck Product main technical parameters Product name: CLW5315GFLT3 type powder material truck appearance size: 10500 x2500x3950 (mm) chassis models: EQ3310LZ3GJ boxcar size: XX (mm) total quality: (Kg) close to 30990 / Angle of departure: 30/18, 31/17 (°) rated quality: after hanging suspended before 18500 (Kg) : 1560/1440132-5/1675 (mm) curb weight:

- Q: What needs to be paid for forklift? How to determine the pros and cons of a forklift?

- The brand used by industries with poor working conditions and heavy workloads can be used as reference objects, and forklifts are good forklifts that can withstand severe environmental tests. The difference between a forklift and a rental car is that taxis are used much larger than the use of a forklift. Just like the amount of private cars can't be compared to taxis. Forklift is used for renting out more of the price and investment time, not quality. Understanding the strength and background of the manufacturer in some areas is more important than understanding a forklift truck on the surface. Unlike cars, the overall quality of each part of a forklift is important, not just the engine

- Q: What kind of equipment is the material handling equipment

- (material handling equipment) used for sports and storage in a facility material or in a website. Material handling equipment can be divided into five categories: Transportation equipment. The device is used for moving material from one place to another (for example, in the workplace, in a dock and a storage area, etc.). The main subclass transportation equipment is conveyor, crane, and industrial truck. Materials can also be transported by hand without equipment.

- Q: What are the components of an automated three-dimensional warehouse?

- Integrated warehouse technology is regarded as the center of material storage in the Integrated Manufacturing System (cims-computer Integrated Manufacturing System). Although the system has been observed in the 1980s, there are not many integrated storage systems in our country. The three phases are the basis for the integration of people, equipment and control systems. In the early 1970s, our country began to study the stereoscopic warehouse of the roadway stacker. In 1980, the first automatic three-dimensional warehouse, which was developed by the Beijing institute of mechanical industry automation, was put into operation in Beijing automobile manufacturing plant. Since then, the warehouse has developed rapidly in our country. According to the incomplete statistics, our country has built a three-dimensional warehouse nearly three hundred, of which there are more than 30 fully automatic three-dimensional warehouses. Our country's automatic warehouse technology has realized the integration of other information decision-making system, and is doing the research work of intelligent control and fuzzy control

- Q: What is the difference between the code for the parts code?

- The parts code is "machine parts codename + parts use range codename + parts drawing number" Because materials are more widely included, the material encoding is more complex and more diverse. The types of materials can be roughly divided into raw materials (black, non-ferrous), wool embryo (forging, casting), standard parts, accessories, home-made parts, components, semi-finished and finished products, products including tooling, labor insurance supplies, energy and so on. The coding of materials can be divided into the storage, technical, classification, the material and the standard.

Send your message to us

Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches