Geotextile UPSC Anti-Skid Needle Punched Non Woven Geotextile Cmax

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

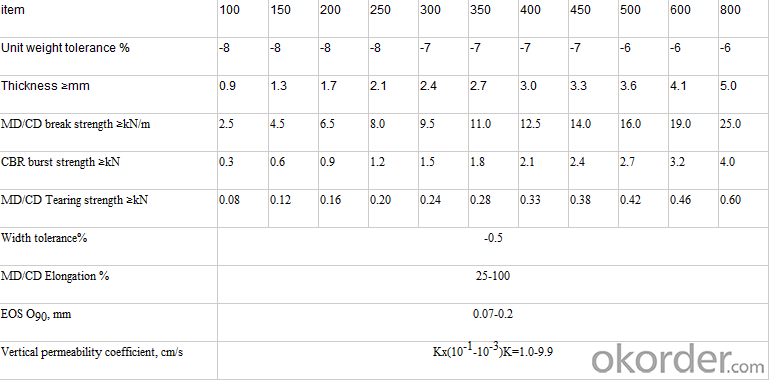

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

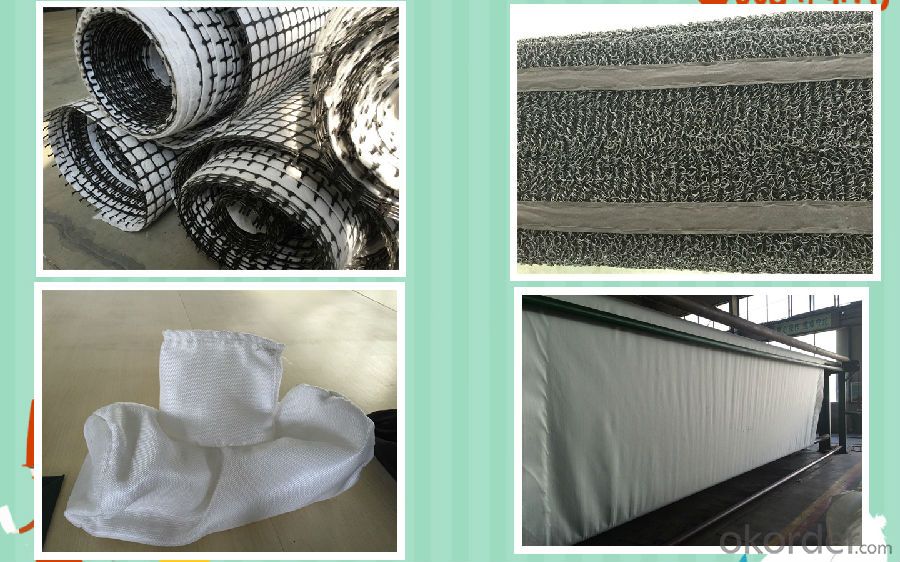

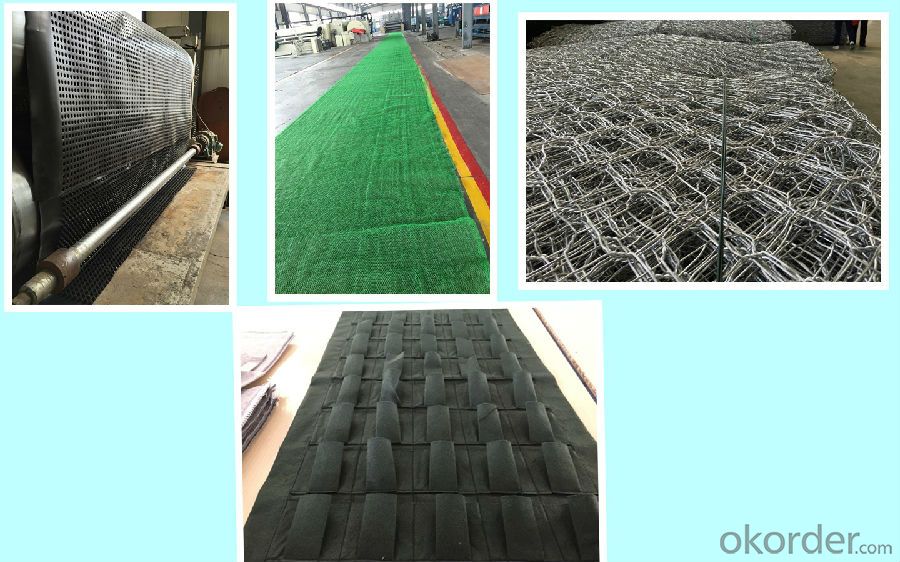

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in underground gas storage projects?

- Yes, geotextiles can be used in underground gas storage projects. Geotextiles are often used as reinforcement materials to stabilize the soil and provide additional support for underground structures like gas storage facilities. They can help prevent soil erosion, control groundwater flow, and improve the overall stability and safety of the storage site.

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the porosity of the fabric, the size and shape of the openings or pores in the fabric, the fabric thickness, and the surface roughness of the fabric. Additionally, the type and quality of the fibers used in the geotextile can also impact its hydraulic conductivity.

- Q: Can geotextiles be used in landfill lining systems?

- Yes, geotextiles can be used in landfill lining systems. Geotextiles are commonly employed as part of the composite liner system to prevent leachate seepage and provide reinforcement. They can act as a barrier between the waste and the soil, reducing the potential for contamination and enhancing the overall performance of the landfill lining system.

- Q: What are the advantages of using geotextiles in groundwater protection systems?

- Geotextiles offer several advantages in groundwater protection systems. Firstly, they act as a physical barrier, preventing the migration of pollutants and contaminants from seeping into the groundwater. This helps in safeguarding the quality and purity of the water source. Secondly, geotextiles provide filtration and separation capabilities, allowing water to pass through while retaining any suspended solids or particles. This enhances the overall efficiency of the groundwater protection system. Additionally, geotextiles are durable, resistant to degradation, and can withstand environmental stresses, ensuring long-term effectiveness in groundwater protection. Lastly, these materials are easy to install and maintain, reducing labor and maintenance costs associated with groundwater protection systems.

- Q: Geotextile manufacturers are what industry

- Petrochemical! Raw materials are all extracted from the oil out of the glial particles!

- Q: Are geotextiles commonly used in canal lining applications?

- Yes, geotextiles are commonly used in canal lining applications. They provide effective erosion control and filtration, preventing the loss of soil particles and maintaining the stability of canal embankments. Additionally, geotextiles can enhance drainage and reduce seepage, improving the overall performance and longevity of canal lining systems.

- Q: How are geotextiles manufactured?

- Geotextiles are manufactured through a process called needle-punching, where synthetic fibers such as polyester or polypropylene are mechanically interlocked together using needles. This method creates a strong and durable fabric with various applications in civil engineering, landscaping, and erosion control.

- Q: Garage roof covered with non-woven or geotextile cloth

- Garage roof, are used geotextile, Huazhi geotextile material manufacturers

- Q: Are geotextiles suitable for use in contaminated soil remediation projects?

- Yes, geotextiles are suitable for use in contaminated soil remediation projects. Geotextiles have been proven to be effective in separating and stabilizing soil layers, preventing soil erosion, and controlling sedimentation. They can also act as a barrier to prevent the spread of contaminants, while allowing for proper drainage and filtration. Additionally, geotextiles are durable, cost-effective, and environmentally friendly, making them a suitable choice for remediation projects.

- Q: Such as title. The manager asked them to be made into a square meter compound. What materials can be used to bind them live. 502 glue can not be filled Cao Cao 丨 not only check the intestine Lu adhesive can not be used, glue rods can be used, but EVA is transparent after the appearance of poor adhesion. Neighborhoods. More

- EVA has a special bonding material ah vendors did not tell you?

Send your message to us

Geotextile UPSC Anti-Skid Needle Punched Non Woven Geotextile Cmax

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords