Aluzinc 0.6mm thickness AZ100 steel coil from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

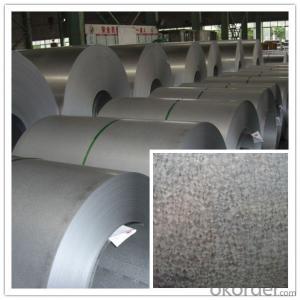

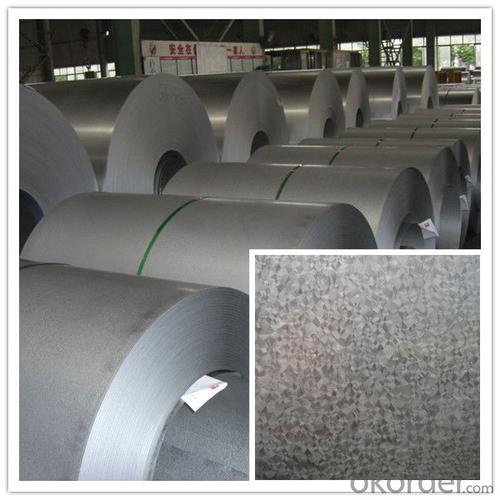

Galvalume steel sheet combines the excellent barrier corrosion protection of aluminum with the galvanic

protection of zinc. The result is a coating that lasts a long time, a coating that provides cut-edge protection

along sheared edges, and therefore, a coating that offers excellent protection to steel sheet. Although there

are a few exceptions, for most applications in most types of environment, Galvalume steel sheet is the preferred

product when long-term resistance to atmospheric corrosion is desired.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

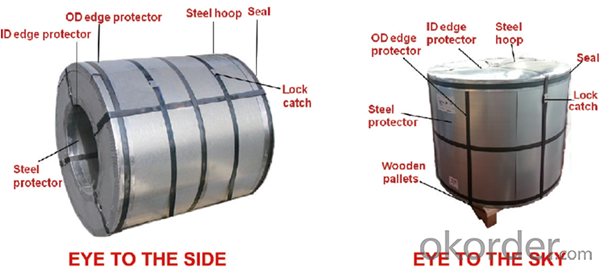

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q: What are the different methods of engraving steel coils?

- Engraving steel coils can be accomplished through various techniques, each presenting its own advantages and applications. Some commonly utilized methods include: 1. Chemical Etching: This involves the application of a chemical solution onto the steel coil's surface, selectively eradicating metal to achieve the desired design. Chemical etching boasts exceptional precision, enabling the creation of intricate patterns and fine details. It is often employed for decorative purposes, such as logos or patterns on steel coils. 2. Laser Engraving: By employing a high-powered laser beam, laser engraving eradicates the top layer of the steel coil, resulting in a permanent mark. This method offers superior precision and accommodates complex designs, logos, or text. Laser engraving is frequently employed for branding purposes or to add identification marks to steel coils. 3. Mechanical Engraving: Mechanical engraving utilizes a cutting tool or diamond-tipped stylus to physically eliminate metal from the steel coil's surface. This technique is renowned for its durability and versatility, capable of creating deep and long-lasting engravings. Mechanical engraving is commonly used for industrial applications, such as adding serial numbers, part codes, or other identification marks to steel coils. 4. Electrochemical Etching: Electrochemical etching, also known as electrolytic etching, employs an electric current to selectively dissolve the metal surface of the steel coil. This technique is frequently employed for marking and branding purposes, as it produces high-quality and permanent engravings. Industries requiring precision and durability, like aerospace or automotive manufacturing, often utilize electrochemical etching. 5. Inkjet Printing: Although not technically engraving, inkjet printing allows for the addition of patterns or designs onto steel coils. This process involves utilizing specialized inks and a digital printing system to directly apply the desired design onto the coil's surface. Inkjet printing is versatile, cost-effective, and provides high-resolution prints, making it suitable for various applications, including decorative or branding purposes. In conclusion, the range of methods available for engraving steel coils offers a multitude of options for creating permanent markings, logos, or patterns. The choice of method depends on factors such as desired precision, durability requirements, and the specific application for the steel coil.

- Q: What are the different types of steel coil coating materials?

- There exist various steel coil coating materials utilized in diverse industries and applications. Some frequently encountered types encompass: 1. Polyester: Renowned for their resilience and ability to withstand weathering, polyester coil coating materials find frequent application in outdoor settings like roofing and cladding. They offer exceptional protection against fading, chalking, and corrosion. 2. Polyvinylidene Fluoride (PVDF): PVDF coil coating materials exhibit remarkable resistance to chemicals, UV radiation, and weathering. They are commonly employed in architectural contexts, providing prolonged color retention and excellent defense against harsh environmental conditions. 3. Polyurethane: Possessing a high degree of flexibility and adhesion, polyurethane coil coating materials prove ideal for scenarios necessitating resistance to abrasion, impact, and bending. The automotive and appliance industries commonly rely on them. 4. Epoxy: Epoxy coil coating materials are celebrated for their remarkable adhesion and corrosion resistance. Industries such as metal furniture, storage tanks, and machinery frequently utilize them to ensure long-lasting protection against chemicals and abrasion. 5. Silicone Modified Polyester (SMP): SMP coil coating materials combine the robustness of polyester with the flexibility of silicone. They are prevalent in agricultural and industrial settings, offering outstanding resistance to chipping, cracking, and peeling. These merely serve as a few instances of the diverse array of steel coil coating materials currently available in the market. The selection of a coating material hinges upon the specific requirements of an application, including durability, weather resistance, chemical resistance, and aesthetics.

- Q: We bought a new fridge and the magnets don't stick to the front where the stainless steel is.

- This Site Might Help You. RE: Why don't magnets stick to stainless steel? We bought a new fridge and the magnets don't stick to the front where the stainless steel is.

- Q: What are the advantages of using steel coils in the manufacturing industry?

- Using steel coils in the manufacturing industry offers several advantages. Firstly, steel coils are renowned for their strength and durability, making them an ideal choice for various manufacturing processes. They can withstand heavy loads and resist deformation, ensuring that the final product is reliable and long-lasting. Secondly, steel coils are highly versatile and can be used in a wide range of applications across different industries. They can be shaped, molded, or cut into different forms and sizes, catering to diverse manufacturing needs. Additionally, steel coils are cost-effective. Their strength and durability result in a longer lifespan compared to other materials, reducing the need for frequent replacements and leading to cost savings in the long run. Furthermore, steel coils have excellent thermal conductivity, meaning they can efficiently transfer heat. This makes them suitable for applications that require temperature regulation, such as in the automotive and HVAC industries. Moreover, using steel coils in the manufacturing process contributes to a more sustainable and eco-friendly approach. Steel is one of the most recycled materials globally, reducing the need for raw materials extraction and energy consumption, and resulting in a reduced carbon footprint. Furthermore, steel coils can be coated with protective layers to enhance their resistance to rust and corrosion. This makes them suitable for outdoor applications or industries with corrosive environments. Lastly, steel coils offer consistent quality and uniformity in terms of dimensions, mechanical properties, and surface finish. This ensures that the end products meet the required specifications and maintain a high level of quality. To summarize, the advantages of using steel coils in the manufacturing industry include their strength, durability, versatility, cost-effectiveness, excellent thermal conductivity, recyclability, corrosion resistance, and consistent quality. These benefits make steel coils a popular choice for various manufacturing processes across different industries.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored in large warehouses or outdoor storage yards. They are stacked horizontally on top of each other, with wooden or steel supports placed between each coil to prevent damage. When it comes to transportation, steel coils are usually loaded onto flatbed trucks, railcars, or shipping containers. Specialized equipment such as coil racks or coil cradles may be used to secure and stabilize the coils during transport.

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials. This coating can provide an extra layer of protection against fire hazards, reducing the risk of ignition and spread.

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. Ceramic coatings provide a protective layer that enhances the corrosion resistance, heat resistance, and durability of the steel coils. Additionally, ceramic coatings can also offer improved electrical insulation and thermal barrier properties.

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- saw it yesterday and it was great. all the complaints about it being gloomy...nonsense really. how would u feel if u found out ur life was a big question mark THEN u grow up only to get tossed in giant sh*t storm. many right now are excluding this is a story driven movie/character. u can't go in expecting anything with this movie especially ANY comparison to precious films. between Reeves and Cavill... I'm not gonna make that decision yet. this portrayal was one of a complete serious nature. u only get a couple glimpses of other emotions. the ending was a great lead off in which the sequel will showcase a lot more emotion within the character guaranteed. for now Reeves is still the best. until we all see Cavill display a full form of charm and charisma then the entire debate is really pointless

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knives

Send your message to us

Aluzinc 0.6mm thickness AZ100 steel coil from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords