Aluminum T Extrusion Profiles - Cold Rolled Aluminum Sheet Cold Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

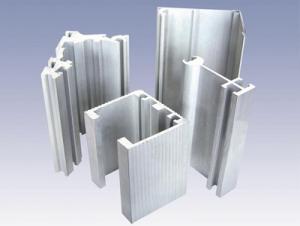

1.Structure of Product Description

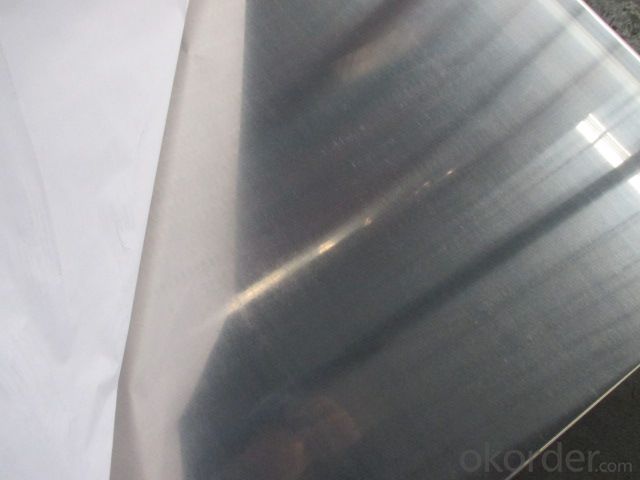

Cold rolled aluminum sheet and cold rolled stainless steel sheet are all widely used in the field of construction field and decoration field, etc.

There are many different grades, su cnbm INTERNATONAL copratoion mainly goods are all including ch as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

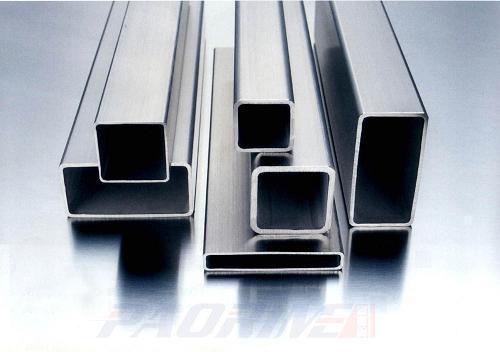

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1000*1000MM,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLAND, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the water resistance properties of aluminum profiles?

- Aluminum profiles have excellent water resistance properties due to their inherent corrosion resistance. The oxide layer that naturally forms on the surface of aluminum provides a protective barrier against water and prevents the metal from rusting or deteriorating. This makes aluminum profiles suitable for various applications in wet or humid environments, such as outdoor structures, marine applications, and plumbing systems.

- Q: Are there any specific regulations or standards for using aluminum profiles in certain industries?

- Industries like construction, transportation, aerospace, and manufacturing have established specific rules and guidelines for utilizing aluminum profiles. Aluminum profiles find widespread use in these sectors. They must adhere to various requirements and standards to guarantee the safety, performance, and quality of the products or structures incorporating them. For instance, in the construction industry, building codes and regulations dictate the proper use of aluminum profiles in windows, doors, curtain walls, and building facades. These codes outline the necessary strength, fire resistance, energy efficiency, and structural integrity of the aluminum profiles employed in these applications. Similarly, the transportation industry relies heavily on aluminum profiles for manufacturing vehicles such as cars, trucks, trains, and airplanes. The Department of Transportation (DOT) and the Federal Aviation Administration (FAA) have established regulations and standards governing the use of aluminum profiles in these applications. These regulations ensure that the aluminum profiles employed in transportation are both robust and lightweight, meeting essential safety requirements. In the aerospace industry, stringent regulations and standards exist for aluminum profiles used in aircraft manufacturing. Aluminum profiles utilized in aircraft must satisfy demanding criteria concerning strength, durability, corrosion resistance, and fire resistance. Organizations like the FAA and the European Union Aviation Safety Agency (EASA) have developed guidelines and standards to ensure the secure and dependable usage of aluminum profiles in the aerospace sector. Manufacturing industries also have their own distinct regulations and standards for utilizing aluminum profiles in various applications. These standards primarily focus on the quality and dimensional tolerances of the aluminum profiles, as well as any specific requirements regarding their use in manufacturing processes or equipment. Overall, specific regulations and standards govern the utilization of aluminum profiles in particular industries to ensure compliance with safety, performance, and quality requirements. These regulations play a crucial role in ensuring that aluminum profiles are utilized in a secure, dependable manner that meets the unique demands of the industry in which they are employed.

- Q: This question asks for the correct procedure to install aluminum profiles.

- <p>To install aluminum profiles correctly, follow these steps: 1. Measure and mark the positions where the profiles will be installed. 2. Clean the surfaces to ensure proper adhesion. 3. Use a suitable adhesive or mechanical fasteners recommended for aluminum. 4. Align the profile with the marked positions and secure it in place. 5. Check for level and plumb, and adjust as needed. 6. Wipe away any excess adhesive and clean the profile. 7. Allow the adhesive to cure according to the manufacturer's instructions. 8. Inspect the installation for any gaps or misalignments and make corrections if necessary. Always refer to the specific installation guidelines provided by the aluminum profile manufacturer for best results.</p>

- Q: What are the surface finishes available for aluminum profiles?

- Some common surface finishes available for aluminum profiles include anodizing, powder coating, polishing, brushing, and chemical etching.

- Q: What is aluminum profile?

- 4) non ferromagnetic; aluminum is non ferromagnetic, which is an important feature of the electrical and electronic industries. Aluminum can not be spontaneous combustion, which is involved in loading and unloading or exposure to flammable and explosive materials is important. 5) machinability; the machinability of aluminum profiles is excellent. In a variety of wrought aluminum and cast aluminum alloys, and in the various states after which these alloys are produced, the machining characteristics vary considerably, which requires special machine tools or techniques. 6) formability; specific tensile strength, yield strength, ductility, and corresponding work hardening rate govern the amount of allowable deformation. 7) recovery; aluminum is highly recycled; the characteristics of recycled aluminium are almost the same as those of primary aluminum. According to the use of classification: 1. construction aluminum profiles (divided into doors and windows and curtain wall two). 2. radiator aluminum profiles. 3. general industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, the electrical machinery industry and clean room with. 4, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing. 5, Mount Aluminum profiles, made of aluminum alloy frame, mounted a variety of exhibitions and decorative paintings.

- Q: This question asks for methods to protect aluminum profiles from damage during the installation process.

- <p>To prevent damage to aluminum profiles during installation, follow these guidelines: Use protective gloves and tools to avoid scratching the surface. Handle the profiles gently to prevent bending or denting. Ensure the work area is clean and free of debris that could damage the profiles. Apply protective films or tapes to vulnerable areas if necessary. Use the correct tools for cutting and drilling to avoid damaging the profile edges. Keep the profiles dry and away from corrosive substances. Always follow the manufacturer's guidelines for installation to ensure proper handling and protection of the aluminum profiles.</p>

- Q: What are the different types of brackets used with aluminum profiles?

- There are several different types of brackets that are commonly used with aluminum profiles. These brackets serve various purposes and help in joining and securing the profiles to create sturdy structures. Some of the most common types of brackets used with aluminum profiles include: 1. Corner brackets: These brackets are used to connect two aluminum profiles at a right angle. They are typically L-shaped and provide a strong and stable connection. 2. T-slot nuts: These nuts are specially designed to fit into the T-slots of aluminum profiles. They allow for the attachment of various accessories and components to the profile, such as panels, hinges, or locks. 3. Angle brackets: Angle brackets are used to create connections between aluminum profiles at different angles other than 90 degrees. They are typically adjustable to accommodate various angles. 4. Joining plates: Joining plates are used to connect two or more aluminum profiles end-to-end, creating longer sections. These plates provide a secure connection and maintain the structural integrity of the profiles. 5. Gusset brackets: Gusset brackets are triangular brackets that are used to reinforce the connections between aluminum profiles. They provide additional strength and stability to the structure, particularly at joints. 6. Panel brackets: Panel brackets are used to attach panels or sheets to aluminum profiles. These brackets typically have a slot or groove that allows for the easy insertion and secure attachment of panels. 7. Mounting brackets: Mounting brackets are used to attach the aluminum profiles to walls, floors, or other surfaces. They provide a secure mounting point for the profiles, allowing for the creation of stable structures. These are just a few examples of the different types of brackets used with aluminum profiles. The specific type of bracket required will depend on the application and the desired structure being created with the aluminum profiles.

- Q: Can aluminum profiles be used in solar panel installations?

- Solar panel installations can utilize aluminum profiles, which are favored in construction and engineering due to their lightweight, durability, and resistance to corrosion. These properties make aluminum profiles an ideal material for solar panel installations. Aluminum profiles can be employed to construct robust frames that securely hold solar panels in place. The lightweight nature of aluminum facilitates easy transportation and installation of the panels, reducing overall installation time and cost. Moreover, the corrosion resistance of aluminum ensures that the frames withstand exposure to various weather conditions, making them suitable for both residential and industrial installations. In addition, aluminum profiles can be easily customized and fabricated to meet specific project requirements. They can be extruded into various shapes and sizes, allowing flexibility in designing frames to accommodate different panel dimensions and orientations. Anodizing or powder coating can also be applied to aluminum profiles for added protection against environmental factors and to enhance the installation's aesthetic appeal. To summarize, aluminum profiles are an excellent choice for solar panel installations. Their lightweight nature, durability, resistance to corrosion, and customization options make them suitable for a wide range of applications, ensuring the longevity and efficiency of the solar panel system.

- Q: RT: you! What are coated aluminum profiles? What's the surface treatment? What's the difference between grain transfer and wood grain transfer? Thank you first!!!

- Aluminum Alloy profiles the most common and most primitive (referred to as aluminum), is Aluminum Alloy itself color, silver white, but this state for a long time, Aluminum Alloy surface will be oxidized into a dark gray or black. In order to solve this problem, the most common practice in our country is to spray a layer of powder (high temperature treatment) on the surface, that is electrostatic powder spraying. Also, fluorocarbon electrophoresis processing processing, wood grain transfer, the transfer grain processing fidelity is not high, in order to understand this problem quickly, the market has a film processing, high fidelity, but because the process requirements must be done in the film before powder spraying treatment, coupled with higher requirement on the film itself (the country is more before foreign or joint ventures), so the production cost is higher, in a second tier city high-grade residential.

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum is a lightweight and durable material that offers numerous advantages for automotive applications. It is highly resistant to corrosion, which is essential for withstanding the harsh conditions within vehicles. Aluminum profiles can be used to create various components in automotive interiors, such as door panels, instrument panels, seat frames, and trim pieces. Additionally, aluminum profiles can be easily formed and shaped to meet specific design requirements, allowing for flexibility in automotive interior design. The use of aluminum profiles in automotive interiors can help reduce the overall weight of the vehicle, resulting in improved fuel efficiency and reduced emissions.

Send your message to us

Aluminum T Extrusion Profiles - Cold Rolled Aluminum Sheet Cold Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords