Aluminum Strips Lowes for Petrochemical Industries with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

*The high export tax of aluminum ingot, the coil has better price than ingot.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

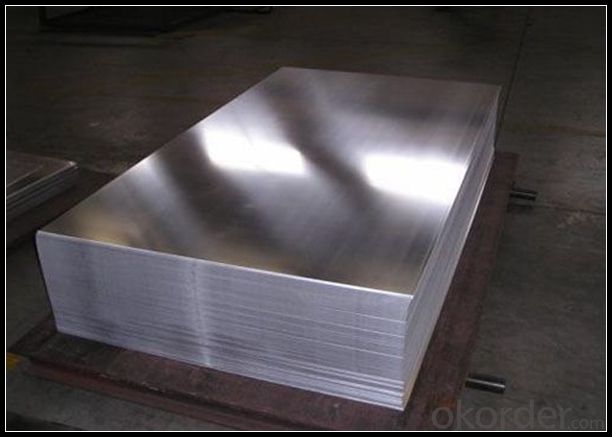

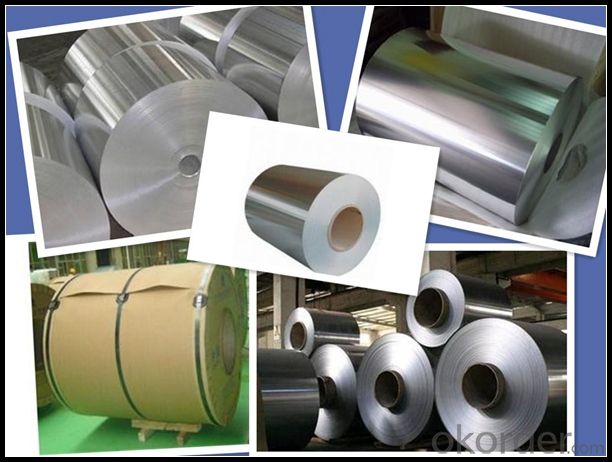

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to utilize aluminum strips for creating signs or banners?

- <p>Yes, you can use aluminum strips to make signs or banners. Aluminum is lightweight, durable, and resistant to weather, making it a popular choice for outdoor signage. It can be cut, bent, and shaped easily to create various designs. Additionally, aluminum strips can be painted or printed on, allowing for customization with text and graphics. However, ensure that the aluminum is of the appropriate thickness and quality for your specific project to maintain its structural integrity and longevity.</p>

- Q: What gas is best for welding aluminum strip?

- If the welded aluminum strip is welded by argon arc welding, it is best to use high purity argon and 5 purity of 9.

- Q: What is the ratio of the thickness of the aluminum strip to the joint of the knife?

- For example, O soft, tear ratio smaller, shear thickness of 70%. However, the H state is hard, the tearing ratio is large, and the shear ratio is small, which is about 30%.

- Q: What benefits does using aluminum strips provide compared to other materials?

- <p>Aluminum strips offer several advantages over other materials, including high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. They are lightweight, which is beneficial for reducing the weight of structures or products. Aluminum's resistance to corrosion means it requires less maintenance and has a longer lifespan. Additionally, its thermal conductivity makes it suitable for applications where heat transfer is important, such as in heat sinks or cookware. Aluminum strips are also easy to work with, allowing for easy fabrication and customization, and they are cost-effective, making them a popular choice in various industries.</p>

- Q: What are the regular maintenance concerns associated with aluminum siding on buildings?

- <p>Aluminum siding is generally low-maintenance, but there are a few issues that may require attention. These include checking for dents or damage caused by impacts, ensuring proper drainage to prevent water damage, and cleaning to remove dirt and grime that can dull the finish. Additionally, it's important to inspect for signs of corrosion, especially in coastal areas with high salt content, and to address any loose or peeling paint to prevent further damage. Regular inspection and minor repairs can help maintain the longevity and appearance of aluminum siding.</p>

- Q: What are the drawbacks or negative aspects associated with the use of aluminum strips?

- <p>The disadvantages of using aluminum strips include their relatively low strength compared to some other metals, making them less suitable for heavy-duty applications. They can also be prone to corrosion, especially in humid environments, which can reduce their lifespan. Additionally, aluminum strips may not be as rigid as other materials, leading to potential issues with structural integrity. Lastly, while aluminum is recyclable, the recycling process can be energy-intensive, and the environmental impact of its production, including greenhouse gas emissions, should be considered.</p>

- Q: The role of aluminum strip in tanks

- Using a crawler is like trying to stretch a tank indefinitely

- Q: Is it possible to use aluminum foil as a material for roofing purposes?

- <p>While aluminum foil itself is not a suitable roofing material due to its lack of durability and structural strength, it can be used as a temporary solution in emergency situations or for small repairs. Aluminum foil is not designed to withstand the elements over time, nor does it provide the necessary insulation or protection against water and wind that a proper roofing material should. For long-term roofing solutions, it's best to use materials specifically designed for roofing, such as asphalt shingles, metal sheets, or tiles, which offer greater durability and weather resistance.</p>

- Q: What factors should be considered to determine if an aluminum strip is suitable for a specific application?

- <p>To determine if a certain type of aluminum strip is suitable for your application, consider the following factors: mechanical properties such as strength and ductility, corrosion resistance, thermal conductivity, and electrical conductivity. Assess the strip's dimensional tolerances and surface finish to ensure they meet your requirements. Check if the strip's formability and weldability align with your manufacturing processes. Also, consider the strip's weight and cost-effectiveness. It's advisable to consult with a material scientist or supplier who can provide specific recommendations based on your application's unique needs.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

Send your message to us

Aluminum Strips Lowes for Petrochemical Industries with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords