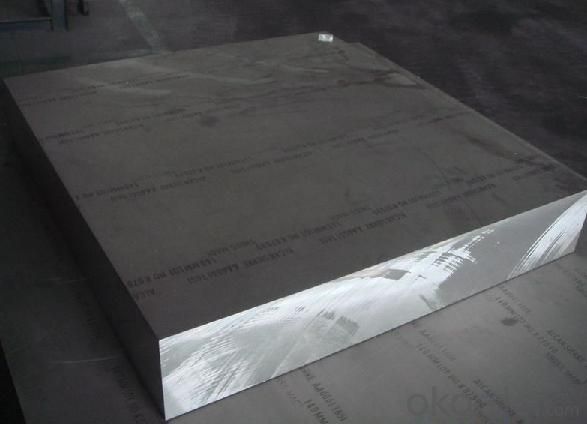

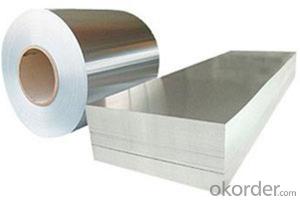

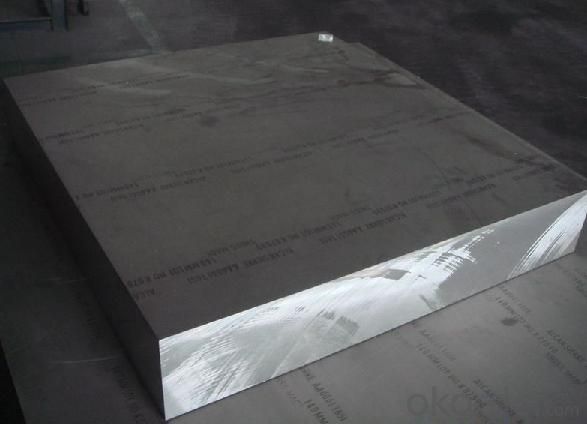

Aluminum Sheets Kansas - 1100 3003 5052 5754 5083 6061 7075 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

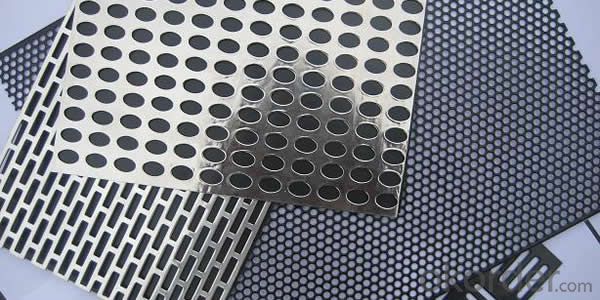

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Application

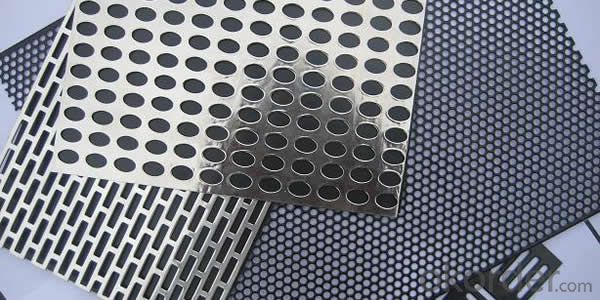

Appplication:construction, decoration, transportation, cookware, machinery, moulding, airplane, PP cap etc

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why CNBM?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- 101 aluminum sheets are excellent for decorative purposes. They are crafted from top-notch aluminum alloy, resulting in a smooth and refined look. Their exceptional resistance to corrosion and ease of cleaning make them perfect for embellishing purposes. Furthermore, these sheets can be effortlessly shaped and cut, enabling the creation of unique designs and personalized touches. Whether it be for interior or exterior decoration, these sheets are versatile and can be utilized for wall cladding, signage, furniture accents, and other applications. With their durability and visually pleasing attributes, 101 aluminum sheets offer a splendid option for adding a touch of sophistication to any environment.

- Q: i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- LEAD

- Q: Is it feasible to recycle aluminum profiles after their use?

- <p>Yes, aluminum profiles can be easily recycled after use. Aluminum is one of the most recycled materials in the world due to its durability and recyclability. Recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. The recycling process is straightforward, involving melting the aluminum, which can then be reformed into new products without losing its properties. This makes aluminum profiles an environmentally friendly choice for many applications.</p>

- Q: Can 101 aluminum sheets be anodized?

- Yes, 101 aluminum sheets can be anodized.

- Q: Can aluminum sheets be used in the automotive industry?

- Aluminum sheets indeed find application in the automotive sector. Being a lightweight and sturdy material, aluminum offers several advantages when it comes to manufacturing automobiles. Car bodies, hoods, doors, and other structural components are commonly produced using aluminum. This helps in reducing the weight of the vehicle, resulting in improved fuel efficiency and enhanced performance. Furthermore, aluminum exhibits remarkable resistance to corrosion, making it ideal for vehicles that face harsh weather conditions. Moreover, aluminum sheets are easily formed, welded, and joined, which adds to their versatility and suitability for various automotive purposes. Consequently, the automotive industry widely embraces the utilization of aluminum sheets due to their numerous benefits.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable.

- Q: Are aluminum sheets suitable for electronic enclosures?

- Yes, aluminum sheets are suitable for electronic enclosures. Aluminum is widely used in the manufacturing of electronic enclosures due to its excellent properties. It is lightweight, yet strong and durable, making it ideal for protecting electronic components. Aluminum also has good thermal conductivity, which helps dissipate heat generated by electronic devices. Additionally, it is non-magnetic and non-sparking, providing safety and preventing interference with electronic signals. Furthermore, aluminum can be easily formed, machined, and finished, allowing for customization and aesthetic appeal. Overall, aluminum sheets offer a reliable and cost-effective solution for electronic enclosures.

- Q: What are the different manufacturing methods for aluminum sheets?

- Aluminum sheets can be manufactured using various methods, each possessing its own unique characteristics and applications. 1. Rolling, the most commonly employed method, involves passing large aluminum slabs through a series of rollers to reduce thickness and increase length. This process ensures consistent thickness and excellent surface finish. 2. Another method, extrusion, utilizes a heated aluminum billet forced through a die, resulting in a continuous sheet. Extrusion allows for the creation of complex shapes and profiles, making it suitable for applications in building construction and automotive components. 3. Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or those with specific alloy compositions. Casting offers unique properties and is prevalent in industries such as aerospace and defense. 4. Cladding entails bonding a thin layer of aluminum to another material like steel or composite materials. This combines the desirable qualities of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets find common use in construction, transportation, and electrical industries. 5. Powder metallurgy involves forming aluminum sheets from powdered aluminum particles. The powder is compacted into the desired shape and then sintered at high temperatures to fuse the particles together. This method is ideal for producing complex shapes and can improve mechanical properties. Considering the desired properties, application, and cost considerations, it is crucial to select the most appropriate manufacturing method for aluminum sheets based on the specific project requirements.

Send your message to us

Aluminum Sheets Kansas - 1100 3003 5052 5754 5083 6061 7075 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords