Aluminum Foil Facing PVC Coated Welded Park Fence Netting

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

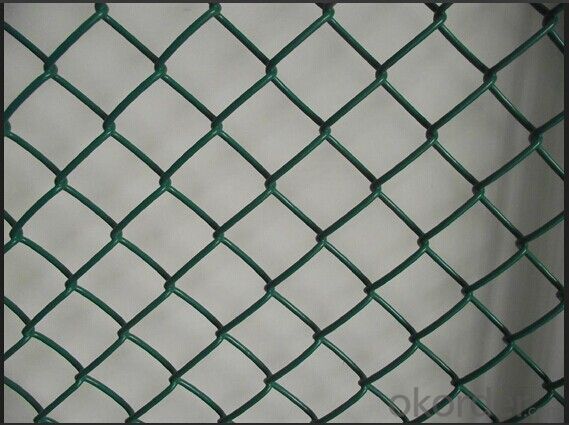

wire mesh

1. CE, ISO9001:2008

2. High Quality Low Price

3.Galvanized wire, PVC coated

4.Delivery: 10 days

Woven wire mesh

Stainless Steel Wire Mesh:

We produce stainless steel wire mesh from first class stainless steel wire material in SUS/AISI 201 202 302 304 310 310S 316 316L 321 430 etc.

Stainless steel wire mesh with its excellent resistance against acid, alkali, heat and corrosion, find extensively uses in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making etc.

Stainless steel wire mesh | ||||||

mesh/inch | wire diameter mm | aperture mm |

| mesh/inch | wire diameter mm | aperture mm |

2mesh | 1.80 | 10.90 | 60mesh | 0.15 | 0.273 | |

3mesh | 1.60 | 6.866 | 70mesh | 0.14 | 0.223 | |

4mesh | 1.20 | 5.15 | 80mesh | 0.12 | 0.198 | |

5mesh | 0.91 | 4.17 | 90mesh | 0.11 | 0.172 | |

6mesh | 0.80 | 3.433 | 100mesh | 0.10 | 0.154 | |

8mesh | 0.60 | 2.575 | 120mesh | 0.08 | 0.132 | |

10mesh | 0.55 | 1.990 | 140mesh | 0.07 | 0.111 | |

12mesh | 0.50 | 1.616 | 150mesh | 0.065 | 0.104 | |

14mesh | 0.45 | 1.362 | 160mesh | 0.065 | 0.094 | |

16mesh | 0.40 | 1.188 | 180mesh | 0.053 | 0.088 | |

18mesh | 0.35 | 1.060 | 200mesh | 0.053 | 0.074 | |

20mesh | 0.30 | 0.970 | 250mesh | 0.04 | 0.061 | |

26mesh | 0.28 | 0.696 | 300mesh | 0.035 | 0.049 | |

30mesh | 0.25 | 0.596 | 325mesh | 0.03 | 0.048 | |

40mesh | 0.21 | 0.425 | 350mesh | 0.03 | 0.042 | |

50mesh | 0.19 | 0.318 | 400mesh | 0.025 | 0.0385 | |

Width of Stainless Steel Wire Mesh: 0.6m-1.5m

| ||||||

Welded Wire Mesh

Reinforcing Mesh Panel Description:

1. Reinforcing Mesh Panel also named Welded Steel Bar panel or Heavy welded wire mesh panel.

2. Wire diameter of Weded Steel Bar Panel: 5mm -16mm

3. The opening of Welded Steel Bar Panel: 75mm-300mm

4. Reinforcing Mesh Panel length: 1m - 12m

5. Reinforcing Mesh Panel width: 100cm-240cm

6. Reinforcing Mesh Panel, Wire profile: Smooth profile, or ribbed profiile.

7. Reinforcing Mesh Panel, type of material: Q235

8. Reinforcing Mesh Panel Standard size: 2.4m x 6m

9. Australian Standard: SL72,SL82.

- Q: This question asks for the most suitable materials to be used in conjunction with aluminum foil facing.

- <p>The best materials to use with aluminum foil facing are those that are compatible with its properties. For insulation, materials like fiberglass or polyethylene foam are ideal due to their thermal resistance. For construction, materials such as plywood or drywall can be used as a backing, as they provide a sturdy base. When it comes to sealing, materials like butyl rubber or silicone are effective because they adhere well to aluminum foil and create a watertight seal. It's crucial to select materials that won't react chemically with aluminum and can withstand the environmental conditions in which the foil facing will be used.</p>

- Q: Is it possible to use aluminum foil facing more than once?

- <p>Yes, you can reuse aluminum foil facing for multiple uses. However, it's important to note that the effectiveness of the foil decreases with each use due to wear and tear. It may become less reflective and less effective at insulating heat. Make sure to clean it thoroughly after each use and inspect for any damage or tears before reusing. For best results, limit the number of times you reuse the foil facing to maintain its performance.</p>

- Q: Is it safe to use aluminum foil with a reflective side to wrap vegetables or fruits?

- <p>Yes, you can use aluminum foil facing to wrap vegetables or fruits. Aluminum foil is a versatile kitchen tool known for its heat conductivity and non-stick properties. The shiny side of the foil, often referred to as the 'facing', is safe for food contact and does not release harmful substances when used properly. It's commonly used to wrap foods for cooking, preserving freshness, or for storage. However, it's important to ensure that the foil does not tear or come into direct contact with the heat source as it could lead to burning or melting, which is not safe. Always follow the manufacturer's guidelines for safe usage.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foils, highlighting their differences.

- <p>Aluminum foil facing is distinct from other metal foils due to its specific properties. It is lightweight, highly reflective, and offers excellent heat conductivity, making it ideal for insulation and cooking applications. Unlike other metal foils, aluminum foil is non-toxic and can be safely used in food packaging and preparation. It is also corrosion-resistant and has a lower melting point compared to metals like steel or copper, which affects its usability in various industries. Additionally, aluminum foil is more affordable and widely available than some other metal foils, contributing to its popularity in everyday use.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: What are the potential health hazards related to using paper plates in comparison to aluminum foil facing?

- <p>There are generally no significant health risks associated with using paper plates instead of aluminum foil facing. Paper plates are made from food-grade materials and are designed to be safe for contact with food. However, it's important to ensure that the paper plates are free from any harmful chemicals or dyes, and are not contaminated during production or storage. Aluminum foil facing, when used properly, is also safe, but it can leach aluminum into food if heated excessively or used with acidic foods. Both options are generally considered safe, but it's always best to use products from reputable manufacturers and follow usage guidelines.</p>

- Q: Is it possible to use materials other than plastic for food wrapping?

- <p>Yes, you can use alternatives to plastic for food wrapping. Materials such as beeswax wraps, silicone sheets, and reusable cotton or linen wraps are eco-friendly options that can be used to cover bowls or wrap food items. These materials are reusable, washable, and can be composted at the end of their life cycle, reducing waste and environmental impact. Additionally, parchment paper and aluminum foil can be used as disposable alternatives, though they are not as sustainable as reusable options.</p>

- Q: This question asks about the various types of aluminum foil facing used in construction and insulation materials.

- <p>Aluminum foil facing is used in various applications, including insulation and construction materials. The different types include: 1) Plain Foil Facing, which is a smooth, uncoated aluminum foil; 2) Coated Foil Facing, which has a protective coating applied to one or both sides; 3) Laminated Foil Facing, where aluminum foil is bonded to other materials like polyester or polyethylene; 4) Embossed Foil Facing, featuring a pattern or texture on the surface for added strength or aesthetic purposes; and 5) Reinforced Foil Facing, which incorporates additional materials to enhance durability and tear resistance.</p>

- Q: This question asks for a comparison between domestic and foreign aluminum foil, specifically focusing on their differences.

- <p>The differences between domestic and foreign aluminum foil facing primarily lie in material quality, manufacturing processes, and market positioning. Domestic aluminum foil often uses locally sourced materials and may have variations in thickness and quality, while foreign foil might employ higher-grade materials for enhanced durability and consistency. Manufacturing processes abroad may incorporate advanced technology, leading to better surface smoothness and uniformity. Additionally, foreign aluminum foil is often marketed as premium, targeting niche segments with specific requirements for quality and performance. Domestic foil, on the other hand, is generally more affordable and caters to a broader market, including everyday household use.</p>

- Q: What are the negative effects on the environment when aluminum foil facing is utilized?

- <p>The environmental impacts of using aluminum foil facing include increased waste generation due to its non-biodegradable nature, leading to landfill accumulation. Aluminum production is energy-intensive, contributing to greenhouse gas emissions. Additionally, improper disposal can lead to water and soil contamination. Recycling rates for aluminum are high, but not all foil is recyclable, and the process itself consumes energy. Overall, aluminum foil facing can have significant environmental consequences if not managed responsibly.</p>

Send your message to us

Aluminum Foil Facing PVC Coated Welded Park Fence Netting

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords