Aluminum Foam for Flooring underlayment foam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

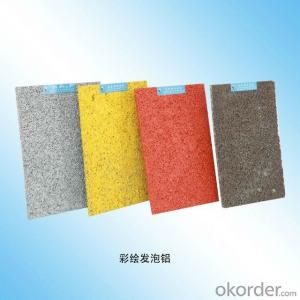

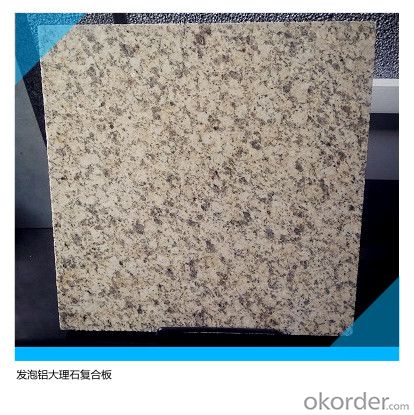

100% Recycling Soundproofing Closed Cell Aluminum Foam Panel

What is AluminumFoam?

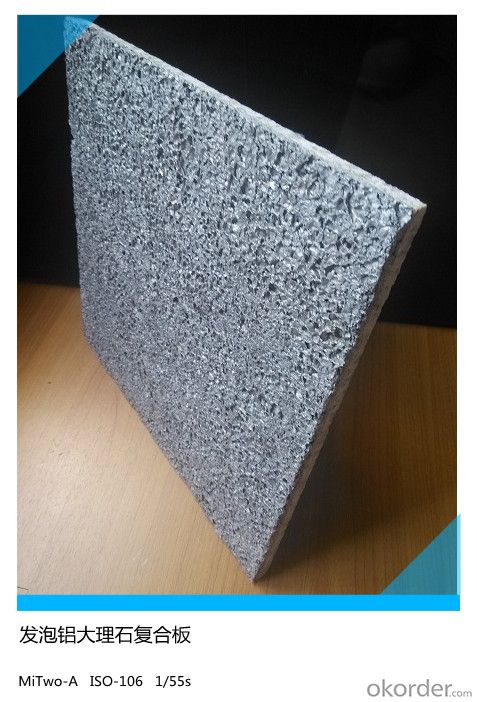

Aluminum foam is a new concept metalmaterial which is foamed in sponge shape after melting aluminum ingot with various chemical ingredients and has many bubble layers inner structure.

Porous material is much lighterthan original one, which is the characteristic of porous. And, it improves the ability of energy absorption and reduces the abilityof thermal and electrical conductivities than original metal materials. Inaddition, porous material has wide applications as well as excellent ability ofsound absorption and permeability of liquid, air, etc.

Aluminumfoam, a metal itself, can be applied to aerospace aviation required the thermostability over 200℃. It is a 100% recyclabl ecofriendly material and absolutely will not produceharmful substances no matter in the process of producing, using or abandoning.

Main properties of aluminum foam

Density is 0.2~0.4g/cm3 (Aluminium1/10,Iron1/30, and Wood 1/4)

Soundabsorption

Porous structure has a good soundabsorption.

Aluminum foam sound-absorbing materialcan be used in the inner decoration of buildings (walls, ceiling and floor),railway, highway, factories, mechanical equipment and any other fields.

Suitable for noisy place.

100%non-flammability and no toxic gas released when burning.

Non-combustibility TEST verified to be qualified. <KIMM; IMO A.799 (19)>

I grade Non-flammability TEST ofaluminum foam surface verified to be qualified. <KICT; KS F2271>

Energyabsorption

Porous structure can effectively absorbenergy.

Have a great effect on energyabsorption after a high impact.

Firstly acquired the national SB5class (Guard rail shock-absorber)

Electromagnetic wave shielding ability

Aluminum foam has a function ofabsorbing electromagnetic wave

Widely used in military (stealth materials),TV station, hospital and any other electromagnetic shielding places.

100% recyclable Aluminum foam is nonpoisonous, odorless andharmless, no toxic gas released when burning.

Aluminum foam can be produced by recycled aluminum andits scraps.

ProductFeatures

Item | Aluminum foam composed panel | Aluminum honeycomb plate |

Material | Aluminum | Aluminum |

Structure | Aluminum plate(GRP plate) aluminum foam aluminum plate(GRP plate) | Aluminum plate(GRP plate) aluminum honeycomb aluminum plate(GRP plate) |

(long time immersion and corrosion in water) | Excellent(oxidized pure metal) | Excellent but easy to rust |

Excellent (Non-flammability of pure metal) | General (Glue layer in the middle is not resistant to high temperature) |

ComparisonAluminum Foam with Other Sound-absorbing Materials

Type | Aluminum Foam | Polyester | Glass Fiber | Urethane Form |

Shape |

|

|

|

|

Material | Aluminum | Polyester | SiO2, mineral | high molecular Material |

Acoustic absorption(NRC Standar d) | over 0.70 | over 0.70 | over 0.75 | over 0.65 |

Long-term sound absorption | Permanent | Property is decreased | Property is decreased | Property is decreased |

Eco-friendly | 100% recyclable Eco-friendly | No recyclable, flammable, produce little dust | No recyclable, no flammable, arsenic acid cause gas pollution | No recyclable and flammable |

Materials handling & Constructability | Easy handling, using and working under no protective equipment | No damage when handling and using, easy to work under no protective equipment | Low stability. Easy to cause respiratory disease and skin ailments when touching | No damage when handling and using, easy to work under no protective equipment |

Human harmfulness | Harmlessness | Harmlessness | Harmfulness | Poisonous gas (CO, Cyan gas) release when burning |

Waterproofness & Sound absorption | Waterproofness is excellent , stable form, permanent sound absorption | Waterproofness and adhesion is good, stable form | Absorb moisture and poor drainage cause lower acoustic absorption | Absorb moisture and poor drainage cause lower acoustic absorption |

Non-flammability | Ⅰgrade Non-flammability | Heat-resistant | Easy flammable |

- Q: How does the floor stand up?

- Compound floor tilt solution: First, the tilt of the floor all removed, and then clean the bottom of the brick, after the floor can be put up. Second, to find a cutting machine, the tilt of the floor cut the seam, pay attention to cut just tilted, or can not cut, the tilt of the floor are set off, the following sweep clean, each floor are cast on the floor glue And then stick on it. Third, the floor tilt and burst, usually in the rapid changes in temperature drops of cold or heat occurred, the direct cause of floor tiles and other building materials thermal expansion and contraction and squeeze each other, and more by the improper construction and building materials caused by the quality. Laying floor tiles should be noted that the use of laying floor tile 425 above the cement, sand should be filtered in the coarse sand, according to 1: 2 ratio, and set aside 1 mm expansion joints.

- Q: My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and open the door to open the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, What did not buy, is empty house, there are ten years old furniture. Here to ask, now how can I do, how long this taste can be distributed more

- My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and opened the door to the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, my family did not buy anything, is empty house, also Useful for ten years old furniture. I would like to ask here, how can I do this, how long the taste can be distributed after the brother of the blessing of the well-known version of the pupil to save the old furniture out to find a qualified department to do the air to detect no, then you know how to view the original tie & gt; ;

- Q: Today, the floor factory master over to do the maintenance. Said the third day had to hit the oil, but also to the heating week after the oil. The key is a bottle of oil 150 pieces of 礌 笭 provision of locusts to switch to luxury money. Do not know is not being fooled, and seek advice from the Supreme ah More

- There is no need. Because essential oils are for solid wood flooring. 礌 笭 笭 蝗 转 辨.......... Composite flooring that are oxide, no pores, with the absorption is not. So do not have to listen to their flicker.

- Q: New home decoration! For the floor is not very understand!

- Solid wood!

- Q: Is the composite floor insulator, if the person standing on the composite floor, one hand touch 220V FireWire, will electric shock more

- Composite floor is insulated, but in some cases the insulation effect is not so good, too many impurities

- Q: What is the difference between composite flooring and tiles?

- What is the difference between composite flooring and tiles?

- Q: Home new house to buy a composite floor, the floor is also good, but the manufacturers call the floor paved, will be free to send a floor maintenance, is to brush a layer of floor to protect the floor of the essential oils. They did not want them to do maintenance, but they gave me to do ideological work, have to protect the floor to the floor with a layer of essential oil, but the oil is now as long as a piece of the floor on a piece, and very ugly, but let The effect of the floor worse, and now want to get off this layer of the floor of the oil, the top of the dumplings of the dumplings Lengong Chuanchuan Long how to get it? Do not know what to remove these oils? The The Regret it, the composite floor itself does not need to maintain, to maintain directly to buy real floor. More

- The friend, from the industry, the so-called protection of essential oils is just to place the joints, with wax to fill it, really good floor is not needed, the middle of the U-slot you have to look at the seam will not Will be great, if the big words, it is recommended to call manufacturers to replace, if not, it is recommended that wax is essential oil it, if the top of the top of the dumplings of the dumplings Lengong pass you want to get rid of the most simple way is to buy a small bottle Erguotou down with a cloth made of cotton, so you can go to the wax, do not hurt the floor, I hope my method is useful to you, may you have a happy and happy home

- Q: Will the professionals, strengthen the composite floor really can not touch a drop of water? If it is true

- You ask, it is very professional, all wood products will have a water content of a standard

- Q: Solid wood flooring how much money a square

- Solid wood flooring No

- Q: My home decoration is Chuang floating off spring curled turtle Tong Tong Kun light-colored composite floor, so the floor seam a little bit of dirt, then it looks black, with a mop can only rub the floor, clean the floor seam, I have tried With a wiping cloth wrapped with a finger of a seam of the pull, so the floor is a clean seam, but did not rub half of the tired half. Do not you know that there is no merit to solve this problem? The More

- You can put a little detergent to dilute the brush with a general brush can be a soft brush and then wiped out the red float spring ripe turtle Tong Tong Kun is a rag can be dry. This method will not cause harm to the general floor. I believe that I do floor business. Remember to give me points ah

Send your message to us

Aluminum Foam for Flooring underlayment foam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords