Aluminium Foil for Foam Insulation Rubber Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Structure of Aluminium Foil Description:

Aluminium Foil is structured by aluminium paper, which is the raw material .It is suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

2. Main Features of the Aluminium Foil:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

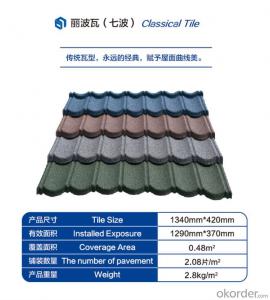

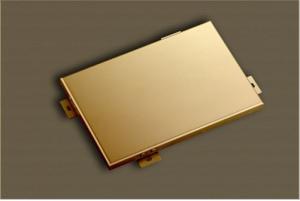

3. Aluminium Foil Images

4. Aluminium Foil Specification

1)Grade: 1050,1060,1070,1100,1200,1235,3003,3102,8011, 8079 etc.

2)Temper: O,H14,H18,H22,H24,H26

3)Thickness: 0.006mm-0.7mm, per customer’s request.

4)Width:15mm-1500mm

We produce the following 3 categories of products:

Aluminum Foil for Food--including food packaging and food container

Aluminum Foil for Packaging--wide application

Aluminum Foil for Industry--used in industrial processing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: On the national standards for aluminum - plastic plates in 2008

- Aluminum plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standards

- Q: Dalian have pottery board, cement board, metal plate, aluminum plate supply agents?

- OKorder Huayuan has a factory office, the main supply Huayuan aluminum plate, aluminum / steel composite panels, stainless steel / aluminum composite panels, copper / aluminum composite panels. There is space in contact.

- Q: Useful aluminum-plastic plate production line made of steel and aluminum did not?

- Yes, stainless steel composite panels are the use of aluminum composite plate production line for production.

- Q: What are the specifications of the aluminum-plastic plate? What are the aluminum-plastic board manufacturers?

- Aluminum plate specifications a lot, you can also order, the main specifications are 1220X2440X4mm; 1220X2440X3mm

- Q: 2017 aluminum-plastic board how the trend?

- Aluminum industry trend research report is through the aluminum plate industry market operation of many factors carried out by the investigation and analysis, grasp the aluminum plate industry market operation law, so the future development trend of aluminum industry characteristics, market capacity, competitive trends, sub-downstream market Demand trends and so on. First, the aluminum industry trends research report analysis of the main points include: 1) aluminum industry trends analysis. Through the analysis of the factors affecting the development of aluminum industry, the paper summarizes the characteristics of the overall operation trend of aluminum industry in the future; 2) predicts the development and trend of aluminum plate industry. Forecasting the development of production and its trends, which is the forecast of the supply of goods and its trends in the market; and 3) forecast the market capacity and change of the aluminum industry. Comprehensive analysis of the aluminum industry during the forecast production technology, product structure adjustment, forecast the demand for aluminum industry structure, quantity and trends. 4) forecast the aluminum market price changes. The price of the inputs and the sales price of the products are directly related to the profitability of the enterprises.

- Q: 3d board and aluminum plate prices? What kind of price?

- This is to sub-material, generally relatively high prices of aluminum-plastic plate

- Q: It is good for aluminum manufacturers of aluminum alloy cans

- I plant generally use 5083,5454 aluminum

- Q: What kind of material is made of aluminum-plastic plate?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: On the Kyrgyzstan and auspicious brand of aluminum plastic plate which is good

- Now the material is not much, auspicious brand can be a good point.

- Q: Why aluminum-plastic composite board in the cutting of the inner aluminum and polyethylene plastic, should retain not less than 0.3mm thick polyethylene plastic?

- But in the construction of specific operations, in order to prevent the slot when scratching the surface layer of aluminum

Send your message to us

Aluminium Foil for Foam Insulation Rubber Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords