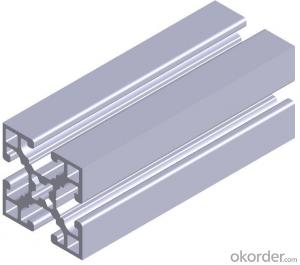

Aluminum Cladding Profiles for Heat Radiator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum profile.heat sink profile

1.Short lead time: 7-15days.

2.professional technology supports.

3.Factory direct price

aluminum profile,industrial aluminum extrusion, construction aluminum profile

Feature:

Specification: according to your aluminum profile drawing or sample

Alloy Code: 6063-T5.6061-T6 o

Surface treatment:

Mill finish

electrophresis

Anodized(silver anodizing,bronze anodizing,champagne anodizing,etc.),

powder coating (need your confirmation by the panton colour, such as RAL9001 )

Length: no more 6.0 M

Sample time: about 13 days o

Lead time:

about 20 days for 1x40' feet

package:

Shrink film and wrapper, kraft paper ,plastic film or per client's requirement.

price: A00(SMM)+Processing fee

payment :

30% deposit +70% before the delivery or against the copy of B/L

delivery : 15-25 days after the deposit confirmed

- Q: This question asks for methods to reduce waste associated with the production and utilization of aluminum profiles in the construction industry.

- <p>To minimize waste during the production and use of aluminum profiles in construction, one can adopt several strategies: 1. Optimize production processes to reduce material waste by using precision cutting and advanced manufacturing techniques. 2. Implement recycling programs to repurpose scrap aluminum, reducing the need for raw material extraction. 3. Design buildings with modular aluminum components that can be easily disassembled and reused in future projects. 4. Educate construction workers on proper handling and storage to prevent damage and waste. 5. Use computer-aided design (CAD) to accurately plan material requirements, minimizing offcuts. 6. Choose sustainable aluminum sources and suppliers that prioritize waste reduction. 7. Regularly audit and update production methods to incorporate new waste reduction technologies and practices.</p>

- Q: Can aluminum profiles be used in the construction of amusement park rides?

- Indeed, amusement park rides can be constructed using aluminum profiles. Aluminum is a favored material for building different parts of amusement park rides because of its lightweight nature and durability. The profiles can be effortlessly molded and joined together to form intricate structures like roller coaster tracks, supports, and frames for other rides. Moreover, aluminum's resistance to corrosion makes it suitable for outdoor settings where the rides are subjected to weather conditions. Furthermore, aluminum is an environmentally friendly option for amusement park ride construction as it can be recycled, showcasing its sustainability. In conclusion, aluminum profiles offer a flexible and dependable choice for creating secure and thrilling amusement park rides.

- Q: Are aluminum profiles painted by powder or by fluorocarbon spray? How can they be distinguished from appearance?

- Aluminum surface treatment for many years, are anodized. In order to be able to achieve a strong film and shiny colors, the domestic and foreign brands of aluminum alloy used to make aluminum doors and windows profiles, have made a serious choice, and finally select 6063 alloy (China as LD31). The alloy extrusion performance characteristics: easy extrusion, medium strength, the key is to have good oxidation resistance, to aluminium profile a good decorative surface. This shows that the oxide film is easy to generate and has high fastness. Oxide film thickness and color difference can be controlled, coloring, adhesion and luster. But the oxidation coloring color only has the white and the bronze color, the color is monotonous. Because the oxidation process involves cleaning, oxidizing, coloring and sealing the aluminum in the oxidation bath. The bath is prepared by a variety of chemical elements, each of a group of chemical composition of aluminum oxide, the bath in the bath is changing, so the variable value, there is always out of aluminum oxide coloring color, individually placed naked eye is not obvious, such as large area together, is very obvious difference show. Therefore, the aluminum curtain wall must not use oxygen extremely positive treatment. Otherwise, the aluminum curtain wall will be very ugly, Chongqing city center trade building is an example.

- Q: How to sell aluminum profile and accessories, how to find customers online?

- Go to the home network. There are all factories inside

- Q: Can aluminum profiles be used for modular exhibition booths?

- Yes, aluminum profiles are commonly used for modular exhibition booths due to their lightweight, durable, and versatile nature. They allow for easy assembly and disassembly, making them ideal for creating flexible and customizable booth layouts. Additionally, aluminum profiles provide a sleek and professional appearance, enhancing the overall aesthetics of the exhibition booth.

- Q: Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Standard number: GB 21351-2008Standard Name: energy consumption quota for aluminum alloy building profile products per unitStandard status: currentEnglish: The, norm, of, energy, consumption, per, unit, product, of, wrought, aluminium,, alloy, extruded, architecture, profiles, for,...Date of implementation: 2008-6-1Promulgated by the Ministry of State Administration of quality supervision, inspection and Quarantine of the People's Republic of China, China National Standardization AdministrationBrief introduction: this standard specifies the Aluminum Alloy profile building energy consumption per unit product of the technical requirements, the scope of statistics and calculation method, calculation range and energy saving management measures. And the calculation and assessment of this standard applies to the enterprise energy consumption per unit product of Aluminum Alloy section building, and the consumption of the new project control.

- Q: This question asks for a method to determine the quantity of aluminum profiles needed for a construction project.

- <p>To calculate the amount of aluminum profiles required for a building project, follow these steps: 1. Determine the project's design and specifications to identify where aluminum profiles are needed. 2. Measure the dimensions of the areas requiring aluminum profiles (length, width, height). 3. Calculate the total linear footage needed by multiplying the dimensions. 4. Consider the profile's cross-sectional area and the project's load-bearing requirements. 5. Account for waste and additional material for joints, connections, and potential errors. 6. Consult with suppliers or use industry-standard formulas to determine the exact quantity of profiles needed. 7. Review and adjust calculations as the project progresses to ensure accuracy.</p>

- Q: What are the different machining options available for aluminum profiles?

- There are several machining options available for aluminum profiles, depending on the desired outcome and the specific requirements of the project. 1. Milling: Milling is a widely used technique for cutting and shaping aluminum profiles. It involves removing material from the workpiece using a rotating cutter. This process can create complex shapes and features such as slots, pockets, and contours. 2. Drilling: Drilling is a machining process that involves creating holes in the aluminum profiles. It is commonly used to attach components or to provide openings for various purposes. Drilling can be done manually or using CNC machines for precision and efficiency. 3. Turning: Turning is a machining process where a single-point cutting tool is used to remove material from a rotating workpiece. This technique is often used for cylindrical or symmetrical aluminum profiles to create features like threads, grooves, and chamfers. 4. Bending: Bending is a process that is used to reshape aluminum profiles by applying force to bend them into the desired shape. It is commonly used for creating curved or angled profiles for architectural or structural purposes. 5. Punching: Punching is a process that involves using a punch and die set to create holes or cutouts in the aluminum profiles. It is commonly used for creating openings for fasteners, connectors, or other components. 6. Sawing: Sawing is a machining process where a rotating blade is used to cut through the aluminum profile. It is commonly used for cutting aluminum profiles to specific lengths or for separating them into smaller sections. 7. Grinding: Grinding is a machining process that involves using an abrasive wheel to remove material from the aluminum profiles. It is commonly used for surface finishing, deburring, or to achieve tight tolerances on the profile's dimensions. Each machining option has its advantages and limitations, and the choice depends on factors such as the complexity of the desired shape, the required precision, and the material properties of the aluminum profiles. Careful consideration of these factors will help determine the most suitable machining option for a particular project.

- Q: Can aluminum profiles be used in aerospace applications?

- Yes, aluminum profiles can be used in aerospace applications. Aluminum has been widely used in the aerospace industry for many years due to its various advantageous properties. Aluminum profiles are lightweight, which is crucial in aerospace applications as it helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and increased payload capacity. Additionally, aluminum profiles possess high strength-to-weight ratio, making them strong enough to withstand the stress and forces experienced during flight. Aluminum is also corrosion-resistant, which is beneficial in the harsh and corrosive environment of aerospace. Furthermore, aluminum profiles can be easily machined and formed into complex shapes, allowing for greater design flexibility. Overall, the combination of lightweight, strength, corrosion resistance, and ease of fabrication makes aluminum profiles an excellent choice for various aerospace applications such as aircraft frames, wings, fuselages, and structural components.

- Q: The number of aluminum profiles can be meters or KG. How exactly is it? How do you understand that?

- According to the calculated root.The general material company is used to calculate the weight or root. Few meters.

Send your message to us

Aluminum Cladding Profiles for Heat Radiator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords