125 Aluminum Sheets in Spfd Mo for Sale - Aluminum Boat for Fishing with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | Allheart | Model Number: | HT625 |

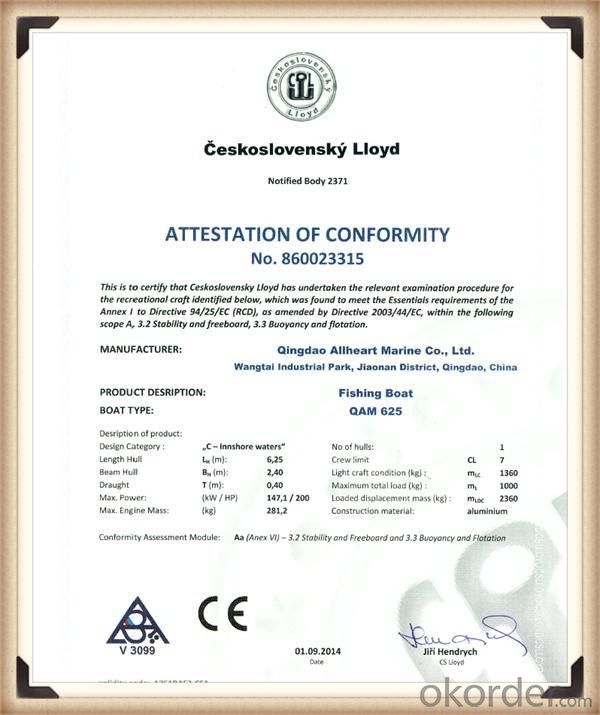

| Hull Material: | Aluminum | Certification: | CE | Capacity (Person): | 10 |

| Length: | 6.25-8m | color: | optional |

Packaging & Delivery

| Packaging Details: | 1)Fishing Boat package according to export standard 2)Fishing Boat package based on seaworthy standard 3)Special package as customer's request |

| Delivery Detail: | within 45 days after 30% deposit |

6.25m cuddy cabin | ||

SPECIFICATIONS | STANDARD FEATURES | STANDARD FEATURES |

Length of Hull: 6.25m | 3 Years Warranty | Seat: Ocean Pro & box storage |

Beam: 2.3m | Rear Ladder | Cleat on Front Deck |

Depth: 1.45m | Windscreen | Floor: Front Casting Platform |

Sides:4mm | Rod Holders (4) | Rail: Transom & Cabin Grabrail |

Bottomsides: 5.00mm | Bollard/Boweye | Rail:Long Side Rails & Low Bowrails |

Topsides: 4.00mm | Anchorwell | Transducer Brackets x 2 |

Transom Material: 5.00mm | Cabin and hard Top | Seat: Cabin Cushions |

Transom Shaft Length: L/L | Double chimes | Cleat On Transom Corners |

Weight (boat only):1155kg | Carpet wooden floor | Twin Battery Box & Switch |

Rec. HP: 150hp | TMC bilge pump | Underfloor Fuel Tank 200 Litres |

Max. HP: 200hp | Under the floor flotation | Seat: Folding Rear Lounge |

Main Motor Weight: 315kg | Cutting Board (Alloy) | fishing tank 60L |

umber of People (Level): N/A | Self Drain Floor Treadplate | Trim Tabs |

Number of People: 8 | Side Pockets (2) | Bait tank 30L |

FAQ

Q: What models do you have available?

A: We currently offer the following layouts for the 498 Series:

Angler 498A - Side Console Boat

Bay Fisher 498F - Center Console Boat

Bay Rover 498R - Runabout Boat

Sports Cuddy 498S - Cuddy Cabin Boat

We also offer 4.6m versions of these boats, they are identical except for the twin rear swimming platforms.

Q: I want to see the boats in person, where can I find them?

A: We have showrooms in Japan (Osaka), Australia (Sydney, Brisbane and Melbourne), and other countries. Please see our website at www.MorningstarBoats.com for a complete list. We are also happy to organize factory tours for you if you would like to come to Taiwan for a visit.

Q: Could you pre-install outboard engines for me?

A: Yes, we can provide Mercury and Evinrude outboards, from 40HP to 115HP.

Q: Could you provide boat trailers?

A: Yes, we have boat trailers specially designed for our aluminum boat hulls.

Q: Do I need drainage for my boat?

A: Aluminium floor without drainage is like most small boats, when you moor it in the harbour and it keeps raining, water will start to accumulate. Once the water level from under the deck is high enough, the automatic bilge pump will be triggered and starts pumping out water.

Our Services

We provide the following products:

14ft, 15ft, 16ft and 17ft aluminum luxury boats (4.6m ~ 4.98m). This is our most popular range.

10ft, 11ft, 12ft, and 13ft small aluminum fishing boats (car toppers and open boats, 3.2m ~ 4.1m) Guranteed low prices!

5.5m Rigid-Hulled Inflatable Boats (RIBs) with aluminum hulls

We provide many customization options.

Contact us NOW for the best boat money can buy!

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- answer is 0.47/107 so each atom weighs 0.004392523364485981308411214953271g that can be rounded to whatever decimal places you want.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, several preventive measures can be taken: 1. Barrier Coating: Apply a barrier coating or paint on the aluminum sheets to separate them from the concrete. This coating acts as a protective layer, preventing direct contact between the aluminum and the concrete, thereby reducing the chances of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can be a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the risk of galvanic corrosion. 3. Surface Treatment: Apply a corrosion-resistant treatment to the aluminum sheets. Anodizing is a common surface treatment method that creates a protective oxide layer on the aluminum surface, making it more resistant to corrosion when in contact with concrete. 4. Use Dissimilar Metals: Avoid using dissimilar metals in contact with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, galvanic corrosion is more likely to occur. Therefore, it is best to use aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Proper Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can accelerate galvanic corrosion. By providing adequate drainage, you can minimize the amount of moisture that comes into contact with the aluminum, reducing the risk of corrosion. 6. Regular Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is observed, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continued protection against galvanic corrosion. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using aluminum sheets with concrete, prolonging the lifespan and integrity of the aluminum and the concrete structures.

- Q: Fiber laser cutting machine and carbon dioxide laser cutting machine, which thin aluminum plate effect is better?

- Fiber laser cutting machine and laser cutting machine equipment of these two kinds of thin aluminum plate effect is very good, mainly to see you at the time of selection, the comparison of two kinds of equipment which is of a higher price, or even a more fit your budget, of course, different brands of different equipment. The price is different, can see or peer application at the time of purchase.I hope I can help you!

- Q: my grandpa gave me a family harloom, a 1971 Honda Trail 90, after it sat in a shed for a good 30 years. i have got most everything in tip top shape except for the polished aluminum has become lightly tarnished. and because i am a perfectionist

- The aluminum has a clear coat on it, get some aircraft stripper (in a spray can) from your auto parts store o take that off, then get a buffing wheel and some brown Tripoli and you can get it looking like new, switch to rouge and yo can get it looking like chrome. you will need to put clear coat back on it or keep it clean and waxed or it will tarnish again.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Can the aluminum sheets be painted or coated with a different color?

- Yes, aluminum sheets can be painted or coated with a different color. Aluminum is a versatile material that can be easily painted or coated to achieve a desired color or finish. This can be done through various methods such as powder coating, anodizing, or using liquid paint. These processes provide a protective layer on the surface of the aluminum sheet while giving it a different color or appearance. The choice of paint or coating will depend on the specific requirements and desired outcome. Overall, painting or coating aluminum sheets is a common practice and allows for customization and aesthetic enhancement.

- Q: Are aluminum sheets resistant to vibration?

- Aluminum sheets, in general, demonstrate resistance towards vibration. Being a lightweight and flexible material, aluminum possesses excellent damping characteristics, enabling it to effectively absorb and dissipate vibrations. Moreover, aluminum exhibits a high strength-to-weight ratio, ensuring its structural integrity remains intact under vibrating conditions. Consequently, aluminum sheets are highly favored in sectors like aerospace, automotive, and construction, where protection against vibrations is crucial. Nevertheless, it is important to acknowledge that the degree of vibration resistance may differ depending on various factors such as the thickness and alloy composition of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: Can aluminum sheets be used for lithographic printing?

- Yes, aluminum sheets can be used for lithographic printing. Lithographic printing, also known as offset printing, relies on the principle that oil and water do not mix. Aluminum plates are used as the printing surface in lithography because they can retain an image when treated with a combination of chemicals. The image areas attract ink, while the non-image areas repel it. This allows for high-quality and precise printing.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- saw web size depends on the thickness and height of sectional material,equipment compatibility and permitted installed saw web size .

Send your message to us

125 Aluminum Sheets in Spfd Mo for Sale - Aluminum Boat for Fishing with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords