Aluminum Sheets Austin - Aluminium Gratings Stair Tread Carbon Steel or Stainless Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

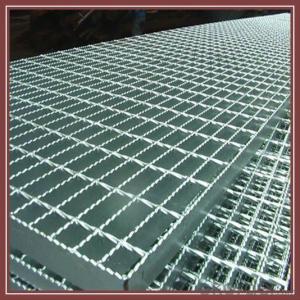

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Yes, aluminum sheets are suitable for pharmaceutical packaging due to their excellent barrier properties, light weight, and resistance to corrosion. They protect pharmaceutical products from moisture, light, and oxygen, ensuring their stability and extending their shelf life. Additionally, aluminum sheets can be easily molded into different shapes, making them a versatile choice for various packaging formats in the pharmaceutical industry.

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Yes, aluminum sheets can be suitable for manufacturing electronics components. Aluminum is preferred for certain applications due to its lightweight, good thermal conductivity, and electrical conductivity properties. However, the suitability of aluminum sheets depends on the specific requirements and design of the electronics components being manufactured.

- Q: 3mm heavy aluminum plate, multiple cubic meters per cubic meter?

- If calculated according to 2.73 density, the theory of a 3MM*1000MM*1000MM weight is 8.19KG. and the specifications of the aluminum flat stacked together what number should be in the 300-333 cubic meters of estimated.

- Q: what's the size of aluminum sheet circle?

- Aluminum sheet circle’s size is usually the width of coil stock (mm) : 500-1250,800-1400,1000-1600, thickness of coil stock (mm) : 0.4-3.0,1.0-6.0, weight of coil stock (kg) : 8000,10000, diameter of blank(mm) : 85-660,85-750,100-900. Aluminum sheet circle is broadly used in electron, daily chemical industry, medicine, education and car accessories industry. Electrical appliance, thermal insulation, machine manufacturing, cars, spaceflight, military industry, mould, construction, printing and other industries. Kitchenware, such as non-stick pan, pressure cooker, etc. and hardware, such as lampshade, shell of water heater, etc. they are one of the highly processed aluminum products with largest consumption.

- Q: What are the effects of utilizing aluminum sheets on the environment?

- <p>The environmental impact of using aluminum sheets includes both positive and negative aspects. On the positive side, aluminum is recyclable, and its use in construction and manufacturing can reduce the need for more energy-intensive materials like steel. However, the production process of aluminum is energy-intensive and generates greenhouse gases, contributing to climate change. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Despite these concerns, aluminum's lightweight nature can reduce energy consumption in transportation, and its durability can extend the lifespan of products, reducing waste. Overall, the environmental impact depends on the balance between these factors and the specific context of use.</p>

- Q: How do aluminum sheets compare to other metals in terms of strength?

- Aluminum sheets generally have lower strength compared to other metals. While aluminum is lightweight and has excellent corrosion resistance, it is not as strong as metals such as steel or titanium. Aluminum has a lower tensile strength and yield strength compared to these metals, making it more susceptible to deformation and failure under heavy loads. However, aluminum can be alloyed with other elements to improve its strength, and specific aluminum alloys can rival or even surpass the strength of some other metals. Additionally, aluminum's strength-to-weight ratio is one of its main advantages, making it a preferred choice in many industries where weight reduction is crucial, such as aerospace and automotive. Overall, while aluminum may not be the strongest metal in absolute terms, it offers a balance of strength, lightweight properties, and corrosion resistance that makes it a versatile material in various applications.

- Q: What are the fire resistance properties of aluminum sheets?

- Aluminum sheets have excellent fire resistance properties due to their high melting point and low flammability. When exposed to fire, aluminum forms a protective oxide layer that acts as a barrier, preventing further heat transfer and combustion. This makes aluminum sheets a reliable choice for applications where fire safety is a concern.

- Q: How do I clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, there are a few steps you can follow: 1. Start by preparing a cleaning solution. Mix a mild detergent or dish soap with warm water in a bucket or sink. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum. 2. Dip a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. Make sure to cover the entire surface, paying extra attention to any stains or dirt buildup. 3. If there are stubborn stains or grime, you can use a non-abrasive brush or a toothbrush to scrub the affected areas. Be careful not to apply too much pressure, as this can scratch the aluminum. 4. Rinse the sheets thoroughly with clean water to remove any residue from the cleaning solution. Ensure that all soap is fully rinsed off. 5. After rinsing, use a clean, dry cloth to wipe off any excess water and dry the aluminum sheets. This helps prevent water spots or stains from forming. 6. To maintain the shine and condition of the aluminum, you can apply a thin layer of aluminum polish or wax. Follow the instructions provided by the manufacturer for the best results. 7. Regularly inspect the aluminum sheets for any signs of damage, such as dents, scratches, or corrosion. If you notice any issues, address them promptly to prevent further damage. Remember, it is essential to handle aluminum sheets with care to avoid any damage. Avoid using abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface. Regular cleaning and maintenance will help keep your aluminum sheets looking their best and extend their lifespan.

- Q: who knows the ceiling technology of aluminum sheet?

- Construction technology of ceiling aluminum sheet: (1) firstly check keel’s quality, the straight shape and uniformly forced state of boom, control the keel’s gap within 500mm, reduce the gap according to design requirement under humid environment. The lower surface of keel is smooth without a sense of bearing down, main device is closely connected with accessories, it can be bound after being confirmed qualified.(2) we should break the board along the cutting line and ensure the margin of cutting board straight and square without any chipping or arris defect. (3) while placing and fixing the board, we can place edge of aluminum-plastic panel(encapsulated edge) in the vertical direction of supporting keel, there is a phenomena of hanging. Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. You can start from a plate angle or middle position, and don’t place them at the same time. Slab joint should be straight and in the same width, without break joint. (4) in the process of joint, Aluminum-plastic panel should be placed closely in the process of butt joint, it can’t be pressed. And the butt joint should be stagger, the butt joint can’t be connected on the same keel. When you use doubling plate, the joints of the second layer board and the first layer board can’t be connected with the same keel, double-deck gypsum board should be staggered joints.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels.

Send your message to us

Aluminum Sheets Austin - Aluminium Gratings Stair Tread Carbon Steel or Stainless Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords