Heavy Aluminum Foil for Industrial Packaging App

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Foil For Different Use

1) Structure of Aluminium Foil Description:

Foil made from a thin leaf of tin was commercially available before its aluminium counterpart. Tin foil was marketed commercially from the late nineteenth into the early twentieth century. The term "tin foil" survives in the English language as a term for the newer aluminium foil.

In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such as plastics or paper to make them more useful. Aluminium foil supplanted tin foil in the mid 20th century.

2)Main features of the Aluminium Foil:

. Flexible and durable

. Light and easy to transport

. Fast delivery

. Item shipped from Dubai warehouse

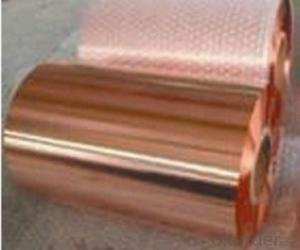

3) Aluminium Foil Images:

4)PE Composite with Aluminium Foil and Paper Specification:

Aluminum Foil

Alloy type: 8011

Temper: O

Tensile Strength(Mpa): 45-110

Elongation(%): 0.5-16max

Thickness: 0.006mm-0.2mm

Width: 40mm-2000mm

Packing: Aluminum Foil are well packed with export standard suitable for long distance sea transportation.

Use: Mainly used in food packing, electric capacitor, air-conditioner finstock, cable foil, household foil, food container foil, soft packing foil, refrigerator, Pharmaceutical, Industries foil and so on.

Inner diameter: 75mm, 76mm, 150mm, 200mm, 220mm, 300mm, 405mm

outer diameter: 100-1500mm

Payment Term: T/T or L/C at sight

Lead time: about 20-25 days

Kind attention: The specifications can be customized according the customers request

5)FAQ of PE Composite with Aluminium Foil and Paper:

1. 30% T/T advance , then balance before shipment or against BL copy. Or 30% L/C payment, balanced duaring 30-60 days.

2. The other specific issues can be negociated.

3. Any problem, feel free to contact us. We will reply as soon as possible.

- Q: I am supposed have a party and dont know what to serve

- I doubt itIf it's an AC line it has to be replacedAluminum is difficult to weld,

- Q: Made from de-hulled and ground black-eyed peas, with corned beef inside and steamed in foil, like a puddingAnyone have the recipe?

- I had the same situation, but i had a Pitbull, he NEVER barks, never jumps most people didnt even know we had a dog, BUT, they evicted us because it is a restricted breed and theres NOTHING you can doMy husband had to get fake DNA results to show them it is not a Pitt but a mix of a lab and a boxerId never give up on my dogIn your case i suggest just moving out, they wont let oyu keep the dog.

- Q: Is it so their cream or liquids wouldn't evaporate, or .?

- I doubt very much that Corebond is fire resistantIt is a polyurethane foamThe Corebond web site does not mention fire resistance, as one would expect if it were fire resistanceCorebond is installed between studs and encapsulated by gypsum boardBy the time Corebond would be involved in the fire, in a typical fire situation, the house would be a goner anywayThe same is true of other foamsFoam in a structure should always be installed in such a manner that it is encapsulated.

- Q: im looking for a good solid bass boat, my price range is at about 10k, meaning used boats are in the equation I just need something cheap, and reliable cause i dont know much about engines and dont wanna get stuck out there No Jon Boats Please i already have one, I Hate Them! :)

- Aluminum boats are great in warm waters but damn cold in cold waterUsed Rangers are around and cheaper than everCut either in half your choice what boat to getJust get the motor tested (always) before buying usedThough my next boat will be a center console with a salt water trolling motor and a round live well.

- Q: Right now, I just recyle paper, but I want to start recycling some more things like cans or cardboardYesterday, I went to recycle my paper in the recycling paper binThere are also other bins and there are lists of which you can and can't put in each binBut I'm confused with some of the things that you can and can't put in each bin:On the paper bin, office paper is on the quot;noquot; listAnd computer and copier paper aren't on any list on the bin at allIs office paper different from copier paper or computer paper? If is, what's the difference, because I'm used to just any white sheet of paper as computer paper or office paper.On the CANS bin, it says on the quot;yesquot; list pet food cans can go in, but it doesnt say anything about vegetable or soup cans on the quot;yesquot; listNiether, does it say on the quot;noquot; list vegetable and soup cans can't go in? Can the vegetable and soup cans go in at all? It doesnt say yes or no!!

- I think office paper is like any other copier paper-they may say no to it for two reasons I can think of-they don't want your documents with addresses and personal info to end up in the bins cause someone might steal the identity, and also if it is a large office, they don't want to recycle your huge amount of paper, you should put up recycle bins and do it yourselfI guess they don't say yes to every possible item, but unless it says aluminum cans I would think they mean pet, soup or vegetable cansAerosol cans should be a no because they are dangerous, but I guess they can handle them? That would be any can that sprays without a pump-they have gas in themI'm glad you want to expand your recycling, but don't forget the best recycling is to put your used items into the hands of someone who needs themLot of things from clothes to furniture can be re-used without a factoryCheck with Goodwill or Salvation Army, churches, homeless shelters, battered women's shelters, etcI worked in a recycling plant for a little whileIt is the sorting that can cost so muchSo please, sort the best that you can, and if you're not sure-askIt is awful for the workers when there are dirty diapers or a milk jug still half full of rancid milk! That's part of the reason I don't work there anymore! Live well and do good.

- Q: Hi, thanks for looking :)I have a small red oak that is around 2m high (7ft?)I've noticed that since early summer some leaves on some twigs have started to slowly die, becoming brownI have also noticed that some leaves in the crown have some pale green or yellow spots, it look like it's bleached or somethingDo you think it needs fertilizer or what's the problem? if you think its fertilizer, how should I fertilize it? Thanks for your help!

- What I know: Saplings need pamperingWhat I don't know: How to pamper a red oakWhat I think: It might be lack of fertilizer(I'm inclined to think that's not it.) It might be not enough waterIt might be insects or a diseaseIt might be one or two freaky leaves that just didn't feel like staying green all summerYou might be having unusual weather as a factorWhat I recommend: 1Basic research on how to care for a new red oakIf that doesn't give you an answer, then2Lots and lots of research on the care of red oak and it's possible pest problemsWhat I'm pretty sure of: You probably don't have to get to step two yet;) All kidding aside (and I did include real ideas too), our city has been pushing free trees on people, simply because our mature trees are past their life expectancy, so we will need new trees to replace themI live in a part of the city with no groundWe have sidewalks for front yards and a slab of cement for backyards, but the city was willing to break open a slab of our front sidewalks and plant the tree for anyone who asked Now we have a whole bunch of saplings with what looks like plastic bibs at their baseThe bibs are to keep the trees watered (pour water down it and the plastic acts like mulch, keeping the water from evaporating quickly.) Consider the economy right now, and yet the city is offering trees and bibs for the treesThose bibs cost money, and yet, it's obvious saplings need to be pampered enough that the city is doing everything in its power to keep those trees alive(After all, if they die, the city has to remove them toolol) In this economy, if government is willing to protect baby trees that much, it tells me baby trees really need to be watered and cared for early in their lives-not so much once they've matured.

- Q: How much

- Dont complication with the fluid filter out substituterather spend $a hundred and twenty.oo for a transmission flushmany cases it is going to shop a rebuild which via the way runs around $1800.00If the Flush doesnt artwork your out an further a hundred and twenty anothe a hundred and twenty on suited of 1800 is the gamblesolid success it worked for me on a ninety one olds 88.

- Q: what happens when copper 2 choride dihydratemixes with aluminum foil?

- The best thing is spray in foam of course this is not cheap at allThe next best thing is fiberglassYou can buy batts and lay them between the rafters or have blown in fiberglass which is better as it has less gaps though it will tend to compress some under it's own weight over timeThis is not a DIY job thoughFiberglass is also dangerous for your lungs so if you install it yourself wear a respirator that is designed for fiberglass useYou don't want thousands of little glass fibers cutting your lungsYou can also use blown in cellulose (ground up paper) which is good though over time it tends to compact under it's own weightIt is very low costIt is treated with Boron to prevent insects/mold from eating it and it also acts as a fire retardantYou can buy it at most home centers an rent the machine to blow it in and the same store.

- Q: i finally found the oil cap to change the oil but i could not find the oil filter does anyone know how or where this oil filter is ???

- There's cat repellent spray you can buy it at Petsmart and Petco.

- Q: My first time making some ribs and I wanted to know how long should I leave them in the oven and how high the temperature should beAlso, how often should I check up on them ?

- Problem with reaming it in place is you don't have a round hole anymore Can you make a plate with the size hole you want and bolt it in placeThen use this as a guide and use the hole saw? I have done something similar to an old truck with a broken bolt i needed to drill outIt worked great for me Or find a way to make that carbide burr stay steadyRig up something

Send your message to us

Heavy Aluminum Foil for Industrial Packaging App

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords