Extrusion Profiles Aluminum Coil in Accordion to European Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil in Acoording to Europ Standard Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Coil in Acoording to Europ Standard Applications:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

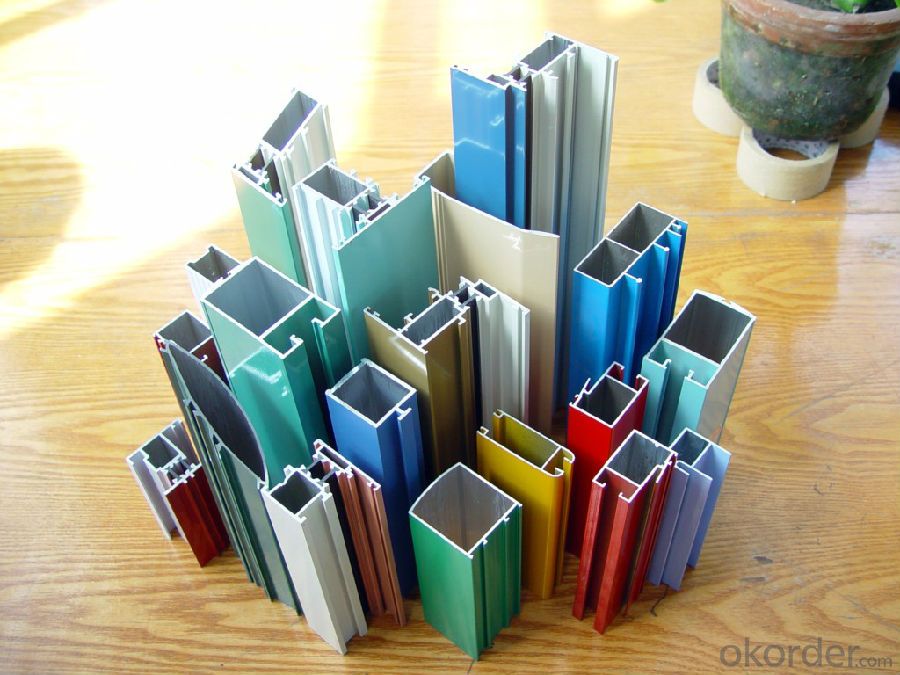

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the AAluminium Coil in Acoording to Europ Standard:

AAluminium Coil in Acoording to Europ Standard Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: This question asks about the impact of aluminum profiles on a building's ability to withstand fire.

- <p>Aluminum profiles can affect the fire resistance of a building in several ways. While aluminum itself has a high melting point and doesn't burn, it does conduct heat, which can lead to rapid temperature increases in the structure. To mitigate this, aluminum profiles used in construction are often coated with fire-resistant materials or combined with non-combustible materials. Additionally, the design of the building and the use of fire barriers can help to slow the spread of fire and heat. It's crucial to follow building codes and standards that specify the appropriate use of aluminum in fire-resistant construction to ensure the safety and integrity of the structure during a fire.</p>

- Q: What are the advantages of utilizing aluminum profiles in construction projects in terms of environmental impact?

- <p>Aluminum profiles in construction offer several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing transportation emissions. It also has a high strength-to-weight ratio, allowing for more efficient use of materials. Additionally, aluminum has excellent thermal conductivity, which can contribute to energy efficiency in buildings. Furthermore, aluminum production technology has advanced to reduce energy consumption and emissions during the manufacturing process. Overall, the use of aluminum profiles can lead to more sustainable and environmentally friendly construction practices.</p>

- Q: What are the methods to prevent water infiltration in the gaps between aluminum profiles during the installation process?

- <p>To prevent water from getting into gaps between aluminum profiles during installation, use high-quality sealants and gaskets. Ensure proper alignment and fit of the profiles to minimize gaps. Install weep holes to allow water to drain out. Apply a water-resistant membrane or flashing behind the profiles. Regularly inspect and maintain the installation to identify and fix any issues promptly. Proper installation techniques and materials selection are crucial to prevent water infiltration.</p>

- Q: Are aluminum profiles suitable for use in sustainable or eco-friendly construction projects?

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their recyclability, which contributes to sustainability. Aluminum is lightweight, strong, and requires less energy to produce and transport compared to other materials like steel. Additionally, aluminum's durability can lead to a longer lifespan, reducing the need for frequent replacements and thus minimizing waste. Moreover, aluminum can be used in energy-efficient designs, such as in window frames that provide better insulation, further enhancing the green credentials of a building.</p>

- Q: How do aluminum profiles perform in terms of thermal conductivity?

- Aluminum profiles exhibit excellent thermal conductivity, allowing them to efficiently transfer heat and manage temperature fluctuations.

- Q: Can aluminum profiles be used in the production of packaging materials?

- Aluminum profiles have the capability to be utilized for the creation of packaging materials. Renowned for its durability, lightweight nature, and strength, aluminum is an excellent selection for packaging applications. These profiles can be extruded into diverse shapes and sizes, accommodating personalized packaging solutions. They can be employed to fabricate packaging containers, like cans, bottles, and tubes, which are commonly utilized for food, beverages, pharmaceuticals, cosmetics, and various other consumer goods. The utilization of aluminum profiles in packaging materials presents numerous benefits, such as resistance to corrosion, impermeability to light, oxygen, and moisture, as well as ease of molding and printing. Furthermore, aluminum is a fully recyclable material, rendering it an environmentally conscious choice for packaging production. Ultimately, aluminum profiles serve as a dependable and effective alternative for the manufacturing of packaging materials.

- Q: This question asks about the various types of aluminum profiles that are utilized in interior design applications.

- <p>Aluminum profiles are widely used in interior design for their strength, durability, and aesthetic appeal. Common types include: 1. Linear Profiles for creating sleek lines in furniture and architectural elements; 2. Structural Profiles for load-bearing structures like beams and columns; 3. Decorative Profiles for ornamental purposes, such as moldings and trims; 4. Frame Profiles for framing pictures, mirrors, and other wall-mounted items; 5. Slatwall Profiles for versatile display systems in retail spaces; 6. Handrail Profiles for stairways and balconies, ensuring safety and style; 7. Window and Door Profiles for modern, lightweight, and energy-efficient applications. Each type is chosen based on the specific design requirements and functional needs of the space.</p>

- Q: Can aluminum profiles be used in the production of transportation containers?

- Yes, aluminum profiles can be used in the production of transportation containers. Aluminum is a lightweight and durable material that is widely used in various industries, including transportation. It offers several advantages for container production, such as corrosion resistance, high strength-to-weight ratio, and ease of fabrication. Aluminum profiles can be used to construct the framework and walls of transportation containers, providing structural integrity while keeping the overall weight of the container low. Additionally, aluminum profiles can be easily customized and shaped to fit specific container requirements. Overall, the use of aluminum profiles in transportation container production offers numerous benefits and is a popular choice among manufacturers.

- Q: I have a disinfection cabinet to cut off a piece of aluminum to install the control board, how to cut? What tool to cut?

- The use of wire saw can be sawed, if you cannot use a wire saw, it can only be used to drill holes along the need the position of the drill hole, finally use a tool to trim it to the edge.

- Q: What are the advantages of using aluminum profiles in the railway industry?

- There are several advantages of using aluminum profiles in the railway industry. Firstly, aluminum profiles are lightweight yet strong. This makes them ideal for use in various railway applications such as train carriages, windows frames, and structural components. The lighter weight of aluminum profiles helps to reduce the overall weight of the train, resulting in lower energy consumption and improved fuel efficiency. It also allows for increased payload capacity, enabling trains to carry more passengers or cargo. Secondly, aluminum profiles have excellent corrosion resistance. Trains are exposed to different weather conditions and environments, including rain, snow, and high humidity. The corrosion resistance of aluminum profiles ensures that they can withstand these conditions without deteriorating or losing their structural integrity. This translates to longer lifespan and reduced maintenance costs for railway operators. Another advantage of using aluminum profiles in the railway industry is their flexibility and versatility. Aluminum can be easily extruded into various shapes and sizes, allowing for customization and design flexibility. This enables manufacturers to create complex and intricate profiles that meet the specific requirements of railway applications. Additionally, aluminum profiles can be easily joined or assembled using various techniques, making them suitable for quick and efficient assembly during train manufacturing or maintenance. Furthermore, aluminum profiles are highly recyclable. With sustainability becoming increasingly important in the railway industry, aluminum's recyclability makes it an environmentally friendly choice. Aluminum can be recycled multiple times without losing its properties, reducing the demand for primary aluminum production and minimizing the environmental impact. Lastly, aluminum profiles offer aesthetic advantages. They can be finished with different coatings or anodized to enhance their appearance and provide additional protection against wear and tear. This allows for the creation of visually appealing train interiors and exteriors, contributing to a positive passenger experience. In conclusion, the advantages of using aluminum profiles in the railway industry include their lightweight yet strong nature, corrosion resistance, flexibility, recyclability, and aesthetic appeal. These benefits make aluminum profiles a preferred choice for various railway applications, contributing to improved performance, reduced costs, and enhanced sustainability in the industry.

Send your message to us

Extrusion Profiles Aluminum Coil in Accordion to European Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords