Aluminum Profiles South Africa - Aluminium Cast Slab Not Alloyed in Coil Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Cast Slab not Alloyed in Coil Form Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Cast Slab not Alloyed in Coil Form:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

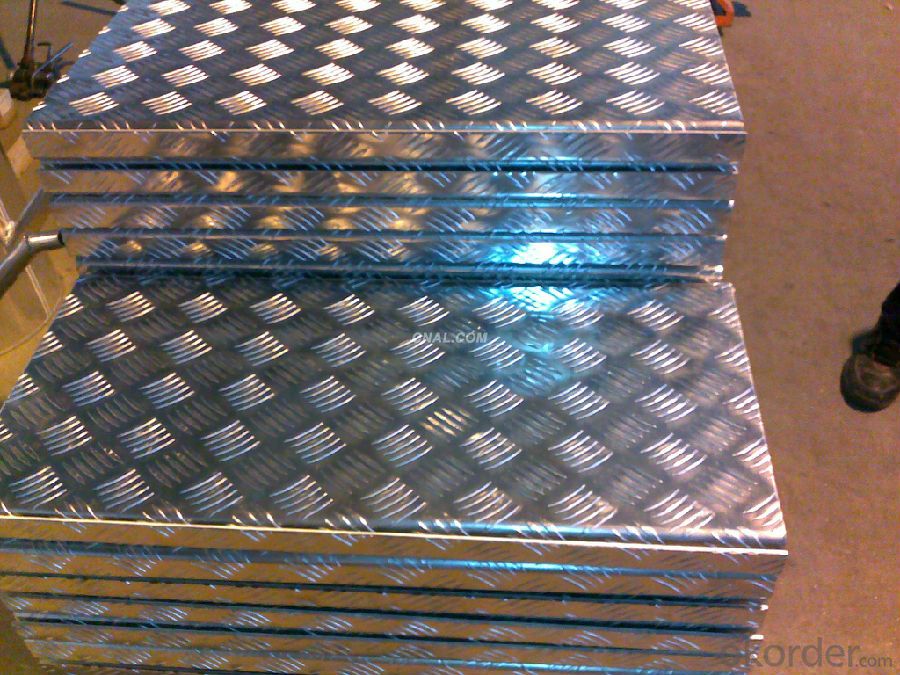

Images of the Aluminium Cast Slab not Alloyed in Coil Form:

Aluminium Cast Slab not Alloyed in Coil Form Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks about the various applications of aluminum extrusions within the automotive manufacturing industry.

- <p>Aluminum extrusions are widely used in automotive manufacturing due to their lightweight, high strength, and corrosion resistance. They are utilized in several areas: 1) Structural components such as chassis, frames, and body parts to reduce vehicle weight and improve fuel efficiency. 2) Engine components to enhance engine performance and durability. 3) Heat exchangers and radiators for effective cooling systems. 4) Crash management systems to absorb impact during collisions. 5) Interior components like dashboards and door panels for lightweight and aesthetic appeal. 6) Electrical components such as battery casings and wiring harnesses. 7) Wheels and suspension components for improved handling and reduced unsprung weight. These applications contribute to the overall performance, safety, and efficiency of vehicles.</p>

- Q: Can aluminum profiles be used in the construction of stadium seating systems?

- Indeed, stadium seating systems can utilize aluminum profiles for their construction. Aluminum, being both lightweight and long-lasting, is frequently employed in a multitude of construction applications, including stadium seating systems. It presents numerous benefits, such as resistance to corrosion, a high strength-to-weight ratio, and ease of fabrication. By customizing and assembling aluminum profiles, seating structures that are sturdy, stable, and aesthetically pleasing can be easily created. Moreover, due to its lightweight nature, aluminum allows for simpler installation and transportation, making it a financially prudent choice for stadium seating systems. All in all, when considering their durability, versatility, and strength, aluminum profiles emerge as an appropriate selection for constructing stadium seating systems.

- Q: This question asks for a comparison between aluminum profiles and other materials concerning cost and availability.

- <p>Aluminum profiles are generally cost-effective and widely available compared to other materials. They are less expensive than materials like stainless steel and titanium, making them a popular choice for various applications. Aluminum is also readily available in the market due to its high demand in industries such as construction, automotive, and aerospace. Additionally, aluminum has a lower density, which means it's lighter and easier to transport and handle, further reducing costs. However, the cost and availability can vary depending on market conditions, geographical location, and specific alloy types.</p>

- Q: This question asks for criteria or methods to determine if a specific aluminum profile is appropriate for a given project.

- <p>To determine if an aluminum profile is suitable for your project, consider the following factors: 1) Load-bearing capacity - Check if the profile can withstand the weight and stress it will be subjected to. 2) Dimensional requirements - Ensure the profile's size and shape match your project's specifications. 3) Corrosion resistance - Verify if the profile is resistant to the environmental conditions it will be exposed to. 4) Surface finish - Confirm if the profile's finish meets your aesthetic and functional needs. 5) Compatibility with other materials - Make sure the profile can be effectively joined or integrated with other materials in your project. Consult with an engineer or the profile manufacturer for specific recommendations based on your project's unique requirements.</p>

- Q: How to distinguish the true and false of aluminum profile

- 1. Light weight 2. 3 and after the incision is white within 4 hard, very fine very hard

- Q: What are the mechanical properties of aluminum profiles?

- Factors such as alloy composition, heat treatment, and manufacturing processes have an influence on the mechanical properties of aluminum profiles. These profiles are known for their excellent strength-to-weight ratio, making them both lightweight and strong. They possess good corrosion resistance, making them suitable for various applications in different environments. Furthermore, aluminum profiles are easily shaped and fabricated into desired designs due to their good formability. They also have high thermal and electrical conductivity, making them useful in applications such as heat sinks and electrical conductors. In addition, their low density contributes to their lightweight nature. In conclusion, the versatile mechanical properties of aluminum profiles make them widely used in industries including construction, transportation, and electronics.

- Q: This question asks for various methods to enhance the heat transfer efficiency of aluminum profiles.

- <p>Improving the thermal performance of aluminum profiles can be achieved through several methods: 1. Material Selection: Choose aluminum alloys with higher thermal conductivity for better heat transfer. 2. Design Optimization: Design profiles with larger surface areas to increase heat dissipation. 3. Fins and Ribs: Incorporate fins or ribs to increase the surface area and enhance heat dissipation. 4. Coating: Apply thermally conductive coatings to improve heat transfer. 5. Insulation: Use thermal insulation to reduce heat loss. 6. Heat Sinks: Integrate heat sinks to dissipate heat more effectively. 7. Composite Materials: Combine aluminum with other materials to improve thermal properties. 8. Manufacturing Techniques: Employ advanced manufacturing techniques to create more efficient profiles. Each method can be tailored to specific applications to achieve optimal thermal performance.</p>

- Q: What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- Q: What are the load-bearing capacities of different aluminum profile shapes?

- The load-bearing capacities of various aluminum profile shapes differ depending on several factors, including the specific aluminum alloy used, the profile's size and dimensions, and its intended application. Aluminum profiles, also referred to as extrusions, are available in a wide range of shapes, which include I-beams, T-beams, square tubes, rectangular tubes, angles, and channels. Each shape possesses a distinct load-bearing capacity due to its structural design and cross-sectional properties. For instance, I-beams exhibit a high load-bearing capacity due to their shape, enabling efficient distribution of weight along the flanges. These profiles are commonly employed in structural applications that require supporting heavy loads. T-beams, on the other hand, possess a load-bearing capacity akin to I-beams but feature a different cross-sectional shape. They find utility in applications necessitating a flat surface on one side, such as in the construction or automotive industries. Square and rectangular tubes are versatile profiles widely used in building structures, frames, and support systems. Their load-bearing capacity is contingent upon the tube's wall thickness and size. Angles and channels, characterized by their L-shaped and U-shaped cross-sections respectively, are commonly employed in the construction and manufacturing sectors. The load-bearing capacity of these profiles is influenced by their size and dimensions. It is important to note that manufacturers typically provide the load-bearing capacities of aluminum profiles, which should be consulted for specific applications. Moreover, engineering calculations and considerations, such as deflection, bending moments, and safety factors, should be taken into account when determining the appropriate aluminum profile shape and size for a given load-bearing requirement.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

Send your message to us

Aluminum Profiles South Africa - Aluminium Cast Slab Not Alloyed in Coil Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords