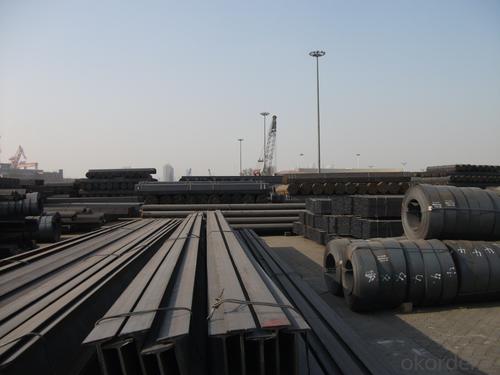

Alloyed Hot rolled I beams/Ibeams GB standard/JIS standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail:packed in bundle, suitable for sea transport (by container) or According to the clients`requirements

Delivery Detail:According to the actual weight

Specifications

joist steel

high quality and factory price

large inventories

short delievery time

good after-sales service

Country of Origin: China

Mill name: Ningbo Preah Vihear Steel Industry Co., Ltd.

Commodity: H beam

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 30days

Price term: CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C At Sight or TT

Product Description

ACCORDING TO STANDARD: JIS G3192 OR GB/T11263-2005

H beam Section sizenma(mm)Weight (kg/m)

Height×BreadthWeb thichnessFlange thichness

100×1006816.9

125×1256.5923.6

150×15071031.1

175×1757.51140.4

200×20081249.9

250×25091471.8

300×300101593.0

300×3001515105.0

350×3501219134.9

400×4001321171.7

148×1006920.7

194×1506929.9

244×17571143.6

294×20081255.8

340×25091478.1

390×3001016104.6

440×3001118120.8

482×3001115110.8

488×3001118124.9

582×3001217132.8

588×3001220147.0

100×50579.3

125×606813.1

150×755714.0

175×905818.0

198×994.5717.8

200×1005.5820.9

248×1245825.1

250×1256929.0

298×1495.5832.0

300×1506.5936.7

346×1746941.2

350×17571149.4

396×19971156.1

400×20081365.4

446×19981265.1

450×20091474.9

496×19991477.9

500×200101688.1

596×199101592.4

600×2001117103.4

700×3001324181.8

800×3001426206.8

900×3001628240.1

- Q: Are steel H-beams suitable for use in high-rise buildings?

- Indeed, steel H-beams prove to be a suitable option for utilization in high-rise constructions. Their reputation for strength and durability renders them an optimal selection for sustaining substantial loads in towering edifices. These beams possess an impressive capacity to bear weight and endure the forces and stresses exerted by the accumulation of multiple floors and the wind loads characteristic of elevated structures. Moreover, their structural shape provides exceptional support and stability, facilitating the efficient distribution of the building's weight. Furthermore, steel H-beams boast easy fabrication and are available in an assortment of sizes and lengths, lending them versatility and adaptability to various high-rise building designs. Consequently, steel H-beams stand as a dependable and extensively employed preference for establishing the structural framework of high-rise buildings.

- Q: What is the weight per metre of 250x250x9x14h steel, please? Do you have any relevant information? Thank you

- The main material of H steel is Q235B, SM490, SS400, Q235B, Q345, Q345B and so on.

- Q: What are the common methods for joining steel H-beams in construction?

- The common methods for joining steel H-beams in construction include welding, bolting, and riveting. Welding involves melting the two beams together at the joint using high heat, creating a strong and permanent bond. Bolting involves using bolts and nuts to secure the beams together, providing a strong and flexible connection. Riveting involves inserting metal rivets through pre-drilled holes in the beams and then hammering them to create a secure connection. Each method has its advantages and is chosen based on the specific requirements of the construction project.

- Q: Can Steel H-Beams be used in hotel or hospitality construction?

- Yes, Steel H-Beams can be used in hotel or hospitality construction. They provide structural stability and load-bearing capacity, making them suitable for supporting heavy loads over large spans. Additionally, steel beams offer flexibility in design and can be easily integrated into various architectural styles.

- Q: What is the cost of steel H-beams?

- The cost of steel H-beams can vary depending on various factors such as the size, grade, and supplier. It is recommended to contact local steel suppliers or check online marketplaces for accurate and up-to-date prices.

- Q: What are the common connections used for steel H-beams?

- Steel H-beams are commonly connected through welding or bolting. Welding involves aligning and welding the ends of the beams using high-intensity heat to create a strong connection. Bolting, on the other hand, utilizes bolts, nuts, and washers to secure the beams together by drilling holes and tightening the bolts. Both methods have their pros and cons. Welding provides a seamless connection that evenly distributes loads, ensuring better structural integrity. However, it requires skilled labor and specialized equipment. Bolting, on the contrary, allows for easier disassembly and reassembly, making it more convenient for certain applications. Nonetheless, it may not offer the same level of load distribution as welding. The choice between welding and bolting connections for steel H-beams depends on factors like the specific application, load requirements, ease of installation, and cost considerations. Engineers and structural designers carefully evaluate these factors to determine the most suitable connection method for each project.

- Q: What is the weight of a standard steel H-beam?

- The weight of a standard steel H-beam can vary depending on its dimensions and specifications. However, a typical standard steel H-beam weighs approximately 33 pounds per linear foot. It's important to note that the weight may differ for different sizes and grades of steel H-beams.

- Q: How do steel H-beams perform in saline or saltwater environments?

- Steel H-beams perform relatively well in saline or saltwater environments, but their durability depends on several factors. First and foremost, the type and grade of steel used in the H-beams play a crucial role in determining their resistance to corrosion. Stainless steel H-beams, for example, are highly resistant to corrosion and are commonly used in marine applications. However, even with stainless steel, prolonged exposure to saltwater can lead to the formation of rust, albeit at a much slower rate compared to other types of steel. To mitigate this, protective coatings such as galvanization or epoxy paint can be applied to the H-beams. These coatings act as a barrier, preventing direct contact between the steel and the corrosive saltwater. Additionally, the design and construction of the structure using H-beams in saline environments should take into account potential corrosion risks. Proper drainage and ventilation systems should be in place to prevent water accumulation and promote air circulation, reducing the likelihood of corrosion. Regular maintenance and inspection are also essential to ensure the long-term performance of steel H-beams in saltwater environments. Inspections should be conducted to detect any signs of corrosion or damage, and appropriate measures should be taken promptly to address these issues. Overall, while steel H-beams can perform well in saline or saltwater environments, factors such as steel type, protective coatings, design considerations, and maintenance protocols all contribute to their performance and durability in such conditions.

- Q: Can steel H-beams be used in gymnasium structures?

- Yes, steel H-beams can be used in gymnasium structures. Steel H-beams are commonly used in construction due to their high strength and durability. They provide excellent support and stability, making them suitable for large open spaces like gymnasiums. Additionally, steel H-beams can be easily fabricated and customized to fit the specific design requirements of a gymnasium. They can withstand heavy loads and provide the necessary structural integrity needed for gymnasium structures.

- Q: What are the considerations for selecting the appropriate grade of steel for H-beams?

- When choosing the right grade of steel for H-beams, there are several important factors to consider. These factors include the desired strength and load-bearing capacity, the specific use and environmental conditions, as well as the cost and availability. Firstly, it is crucial to determine the necessary strength and load-bearing capacity of the H-beams based on their intended purpose and the types of loads they will support. For instance, if the H-beams will be used in construction projects that require them to bear heavy loads, it may be appropriate to use a high-strength steel grade like ASTM A572 or ASTM A992. These grades are known for their exceptional strength and are commonly used in structural applications. Secondly, the specific application and environmental conditions must be taken into account. H-beams can be used in various industries and environments, including construction, manufacturing, and infrastructure projects. In cases where the beams will be exposed to corrosive elements, such as in marine or coastal environments, it may be necessary to use a corrosion-resistant steel grade like ASTM A588 or ASTM A709 to ensure long-term durability. Additionally, certain applications may require specific properties such as fire resistance or impact resistance, which will also influence the choice of steel grade. Cost and availability are also important factors to consider when selecting the right grade of steel for H-beams. Different steel grades vary in terms of cost and availability in the market. It is essential to take the project budget into consideration and ensure that the chosen steel grade falls within the cost constraints. Availability is another crucial factor, as some steel grades may be more readily available than others, which can impact project timelines and logistics. In conclusion, the selection of the appropriate grade of steel for H-beams involves considering factors such as the required strength and load-bearing capacity, the specific application and environmental conditions, as well as cost and availability. By carefully evaluating these factors, engineers and project managers can choose the most suitable steel grade to ensure optimal performance and longevity of H-beams in their intended application.

Send your message to us

Alloyed Hot rolled I beams/Ibeams GB standard/JIS standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords