Hot Rolled H-Beam Structure Steel Q235 Good Price Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled H-Beam Steel

1. Standard: JIS G3101

2. Grade: SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

300*150 | 36.7 |

298*149 | 32 |

200*200 | 49.9 |

294*200 | 55.8 |

346*174 | 41.2 |

350*175 | 49.4 |

244*175 | 43.6 |

175*175 | 40.4 |

294*200 | 55.8 |

298*201 | 64.4 |

346*174 | 41.2 |

350*175 | 49.4 |

400*200 | 65.4 |

396*199 | 56.1 |

450*200 | 74.9 |

446*199 | 65.1 |

340*250 | 78.1 |

500*200 | 88.1 |

300*150 | 36.7 |

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

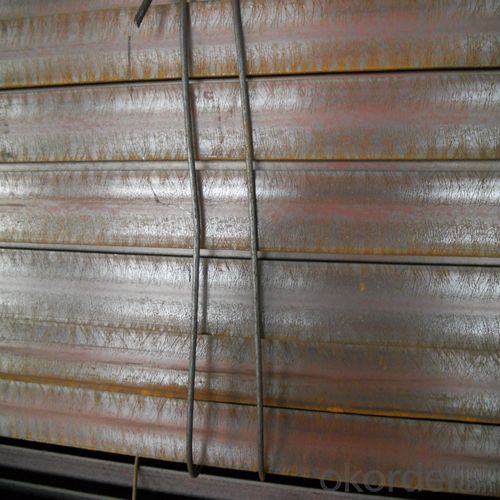

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

- Q: How do you calculate the moment capacity of steel H-beams?

- In order to determine the moment capacity of steel H-beams, it is necessary to take into account various properties of the beam, including its dimensions and material properties. The moment capacity, also referred to as the bending strength or flexural strength, is a measure of the beam's ability to withstand bending forces. To calculate the moment capacity of a steel H-beam, the following steps can be followed: 1. Calculate the section properties: The initial step involves determining the section properties of the H-beam, such as the moment of inertia (I) and the section modulus (Z). These properties are dependent on the dimensions of the beam, including the flange width, flange thickness, web height, and web thickness. These values can be obtained from structural design manuals or the specifications provided by the manufacturer. 2. Determine the yield strength: The subsequent step is to establish the yield strength (Fy) of the steel material used in the H-beam. This value represents the maximum stress that the steel can endure without experiencing permanent deformation. The yield strength can also be obtained from design manuals or the manufacturer's specifications. 3. Calculate the plastic moment capacity: The plastic moment capacity (Mp) is the maximum moment that the beam can withstand before it begins to yield or undergo plastic deformation. It is determined by multiplying the yield strength (Fy) by the section modulus (Z). The formula for calculating the plastic moment capacity is Mp = Fy * Z. 4. Determine the allowable moment capacity: The plastic moment capacity is not always the governing factor in design. Depending on the design requirements and safety factors, the allowable moment capacity may be lower than the plastic moment capacity. The allowable moment capacity is calculated by multiplying the plastic moment capacity by a factor of safety (Fs). The factor of safety takes into account uncertainties in materials, loads, and other design considerations. The formula for calculating the allowable moment capacity is Ma = Mp * Fs. By following these steps, one can ascertain the moment capacity of steel H-beams and ensure that the beam is designed to withstand the necessary bending forces in a safe and efficient manner. It is crucial to consult design codes, standards, and principles of structural engineering to guarantee the accuracy and reliability of the calculations.

- Q: What are the different finishes available for Steel H-Beams, such as galvanized or painted?

- There are several different finishes available for Steel H-Beams, including galvanized and painted options. Galvanized finishes involve applying a protective coating of zinc to the surface of the steel beam. This process helps to prevent corrosion and rusting, making the beams more durable and long-lasting. Galvanized H-Beams are commonly used in outdoor or high-moisture environments where corrosion resistance is essential, such as construction projects near the coast or in areas with harsh weather conditions. Painted finishes, on the other hand, involve applying a layer of paint to the surface of the steel beam. This not only provides a decorative aspect but also acts as a protective barrier against rust and corrosion. Painted H-Beams can be custom-colored to match specific aesthetic requirements or to stand out for safety purposes in industrial settings. Additionally, there are other finishes available for Steel H-Beams, such as powder coating. Powder coating involves applying a dry powder onto the steel beam, which is then cured under heat to create a hard, smooth, and durable finish. This finish provides excellent resistance to chipping, scratching, and fading, making it ideal for applications that require a high-quality, long-lasting appearance. The choice of finish for Steel H-Beams depends on the specific application and the environmental factors they will be exposed to. Galvanized finishes are commonly used in outdoor or high-moisture environments, while painted finishes are versatile and can be customized to match aesthetic or safety requirements. Powder coating offers a durable and attractive finish suitable for various applications. It is important to consider the specific needs and requirements of your project when selecting the appropriate finish for Steel H-Beams.

- Q: Can steel H-beams be used in museum or art gallery construction?

- Yes, steel H-beams can be used in museum or art gallery construction. They are a common choice for structural support due to their strength, durability, and ability to support heavy loads. Steel H-beams can provide the necessary stability and structural integrity required for large open spaces, allowing for flexible and creative design possibilities in museum or art gallery construction.

- Q: Can steel H-beams be used for healthcare facilities or hospitals?

- Yes, steel H-beams can be used for healthcare facilities or hospitals. Steel H-beams are commonly used in construction due to their strength, durability, and ability to support heavy loads. In healthcare facilities or hospitals, steel H-beams can be used in various applications, such as providing structural support for the building, creating partitions or walls, supporting overhead equipment, or even constructing specialized features like surgical theaters or MRI rooms. The versatility of steel H-beams allows for flexible and efficient design options to meet the specific needs of healthcare facilities or hospitals, ensuring the safety and stability of the structures. Additionally, steel is a non-combustible material, which adds an extra layer of safety and meets the stringent fire safety regulations often required in healthcare settings. Overall, steel H-beams offer a reliable and practical solution for construction in healthcare facilities or hospitals.

- Q: Can steel H-beams be used in underground construction projects?

- Yes, steel H-beams can be used in underground construction projects. These beams are commonly used to provide structural support and stability in various construction applications, including underground tunnels, subway systems, and basements. Their strength, durability, and load-bearing capacity make them suitable for such projects.

- Q: Can steel H-beams be painted or coated?

- Steel H-beams are capable of being painted or coated in order to protect them from corrosion, enhance their appearance, and increase their durability against damage. To ensure optimal adhesion, it is crucial to thoroughly clean and prepare the surface prior to painting or coating. The appropriate choice of paint or coating will vary depending on factors like environmental conditions and desired finish. It is advisable to seek advice from a professional or adhere to the manufacturer's instructions to guarantee the proper selection and application of the paint or coating.

- Q: Are steel H-beams cost-effective compared to other beam options?

- Yes, steel H-beams are generally considered to be cost-effective compared to other beam options. There are several factors that contribute to this cost-effectiveness. Firstly, steel H-beams offer a high strength-to-weight ratio, meaning they can support heavy loads while being relatively lightweight themselves. This can result in cost savings in terms of transportation and installation, as well as reduced foundation requirements. Additionally, steel H-beams are durable and have a long lifespan. They are resistant to corrosion, fire, and pests, which means they require minimal maintenance and replacement over time. This can result in significant cost savings in terms of ongoing maintenance and repairs. Furthermore, steel H-beams are readily available and easy to manufacture. This means they can be produced in large quantities at a relatively low cost, making them more affordable compared to other beam options. The availability of standardized sizes and shapes also contributes to their cost-effectiveness, as it simplifies the design and construction process. It is important to note that the cost-effectiveness of steel H-beams can vary depending on the specific project requirements and the local market conditions. However, in general, steel H-beams offer a combination of strength, durability, and affordability that makes them a cost-effective choice for many construction projects.

- Q: Can steel H-beams be customized to specific lengths?

- Yes, steel H-beams can be customized to specific lengths. The length of steel H-beams can be altered during the manufacturing process to meet the specific requirements of construction projects.

- Q: What are the advantages of using steel H-beams in construction?

- Using steel H-beams in construction offers multiple benefits. Firstly, they possess exceptional strength and durability due to their high-quality steel composition. This enables them to withstand heavy loads and extreme weather conditions, making them perfect for vital structures like bridges, buildings, and warehouses. Secondly, steel H-beams have a commendable strength-to-weight ratio. This means that they can support significant loads while being relatively lightweight themselves. Consequently, they are easier to handle and transport during construction while still providing the necessary strength and support. Another advantage of steel H-beams lies in their versatility. They can be easily customized and fabricated to meet specific project requirements. They can be cut, welded, and shaped to create various designs and structures, allowing for innovative and unique architectural concepts. Furthermore, steel H-beams exhibit fire-resistant properties. Being a non-combustible material, steel does not burn or contribute to fire spread. This aspect is especially critical in construction projects prioritizing fire safety, such as commercial buildings or high-rise structures. Moreover, steel H-beams boast a long lifespan and require minimal maintenance. Unlike materials like wood, steel does not rot, warp, or decay over time. Consequently, the need for frequent repairs or replacements is reduced, making steel H-beams a cost-effective choice in the long run. Lastly, steel H-beams contribute to environmental sustainability. Steel is a highly recyclable material, and utilizing steel H-beams in construction reduces the demand for new raw materials. Additionally, steel has a low carbon footprint, making it a sustainable option for construction projects. In conclusion, the utilization of steel H-beams in construction offers a plethora of advantages, including strength, durability, a high strength-to-weight ratio, versatility, fire-resistance, a long lifespan, low maintenance requirements, and environmental friendliness. These advantages make steel H-beams an excellent choice for various construction applications.

- Q: What are the durability considerations for steel H-beams?

- Durability considerations for steel H-beams primarily revolve around corrosion resistance and structural integrity over time. Steel H-beams are generally durable due to their inherent strength and load-bearing capabilities. However, exposure to moisture, chemicals, and harsh environmental conditions can lead to corrosion, which can weaken the beams and compromise their longevity. To enhance durability, protective coatings or galvanization can be applied to steel H-beams to prevent rust and corrosion. Regular inspections, maintenance, and addressing any signs of deterioration promptly are crucial to ensure the continued durability and structural integrity of steel H-beams.

Send your message to us

Hot Rolled H-Beam Structure Steel Q235 Good Price Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords