Terra Bronze Aluminum Coil - Alloy Embossed Aluminum Plate/Sheet 1050 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

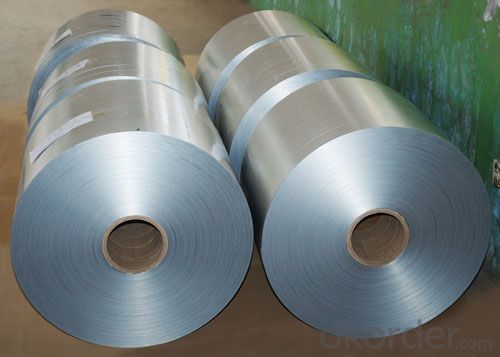

Alloy Embossed Aluminium Plate/Sheet 1050 1060

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Certainly, pharmaceutical packaging can make use of aluminum coils. Aluminum is widely preferred for such purposes owing to its numerous advantageous properties. Notably, its lightweight nature, resistance to corrosion, and exceptional barrier properties render it exceptionally suitable for safeguarding pharmaceutical items against external elements like moisture, oxygen, and light. Moreover, aluminum coils can be conveniently fashioned into various shapes and sizes, thereby offering flexibility to meet diverse packaging requirements. It is also worth mentioning that aluminum is both non-toxic and non-reactive, thereby guaranteeing the safety and overall quality of pharmaceutical products.

- Q: Are aluminum coils compatible with other materials?

- Indeed, other materials can be used in tandem with aluminum coils. Aluminum, being a versatile and extensively utilized substance, readily blends with various materials for different purposes. Take, for instance, the utilization of aluminum coils alongside copper tubing in air conditioning and refrigeration systems to amplify heat transfer efficiency. Furthermore, aluminum coils can be coated or layered with polymers or paints to furnish supplementary safeguard against corrosion, enhance visual appeal, or elevate specific performance attributes. Consequently, aluminum coils exhibit compatibility with a multitude of materials, rendering them apt for an array of applications within industries like construction, automotive, aerospace, and beyond.

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- Well using aluminum heads would be enough to justify doing it because i have aluminum heads and im at 11:1 compression. These heads are 9.5:1 compression with 11:1 compression with twin turbos. Now you are running with straight motor and shoud be fine. Now if you are going to get that pony a supercharger I would suggest getting cast iron heads with a chrome finish to manage this power gain. I have had these for about 40K miles and are still fine. I will eventually change to cast iron with a chrome finish. Hope this helps.

- Q: Briefly describe the process of aluminum production from bauxite. Describe the electrolyte and write the anode and cathode half-reactions.

- Bauxite is purified by washing with sodium hydroxide and then seeding with dry ice. The purified aluminium oxide is then dissolved in molten cryolite at 900 degrees C (the electrolyte). It is electrolysed with grapite anodes and a graphite cathode that acts as the vessel for the reaction. Anode; 2 O2- - O2(g) + 4e Cathode: Al3+ + 3e - Al(l)

- Q: What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for various automotive components, including coils. Its high thermal conductivity also allows for efficient heat transfer, making it beneficial for applications such as radiators and air conditioning systems.

- Q: What are the factors that determine the price of aluminum coils?

- The factors that determine the price of aluminum coils include the current market demand and supply, the cost of raw materials, production and manufacturing costs, transportation costs, market competition, and any additional factors such as tariffs or taxes.

- Q: Are there any specific safety guidelines for installing aluminum coils?

- Installing aluminum coils requires following specific safety guidelines. Consider the following key points: 1. Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, gloves, and a respirator when working in confined spaces or handling chemicals. 2. Handling and lifting: Use proper lifting techniques and equipment to prevent strains or injuries caused by the weight of the aluminum coils. Clear the area of obstacles and ensure enough space for safe maneuvering. 3. Secure the area: Clean the work area and remove any potential hazards or debris to prevent accidents. 4. Electrical safety: Adhere to electrical safety guidelines when dealing with electrical connections or wiring. Turn off the power supply and use suitable tools and equipment to avoid electric shocks. 5. Proper ventilation: Ensure proper ventilation in the work area to prevent the accumulation of harmful fumes or gases, especially during soldering or welding. Use exhaust fans or ventilation systems if necessary. 6. Follow manufacturer's instructions: Always follow the manufacturer's guidelines for handling, mounting, and connecting aluminum coils. Failure to do so may result in substandard installation or safety hazards. 7. Training and expertise: Ensure the installation team is properly trained and experienced in working with aluminum coils to minimize risks and ensure a successful installation. By adhering to these safety guidelines, you can achieve a safe and efficient installation of aluminum coils while reducing the potential for accidents or injuries.

- Q: Which is more unhealthy the bleached parchment paper or the aluminum from the pan?

- This is an easy question to answer. Parchment paper, bleached or unbleached is safer than using aluminum cookware. Unbleached parchment paper is safer than bleached parchment paper. . Cooking parchment is a sheet of bleached or unbleached paper impregnated with silicone. The silicone makes it releasable, that is, food won’t stick to it. . The use of bleached parchment is problematical. It might leach dioxin. It may leach dioxin. Hard to know for sure. The silicon has some sealing effect on the paper. To be absolutely safe, use unbleached parchment. . I use parchment paper to cook chicken in a George Forman Mini Roaster. I fold the perimeter, put the chicken in, punch a hole over the drain hole, fold the ends and side over the chicken, and voila...no major clean up, perfectly cooked moist chicken. . The safest cooking material is silicone baking sheets. Silicone sheets are good for cookies and stuff (and save trees) . If you’re worrying about dioxin leaching out of parchment, you might want to start worrying about the toilet paper you use. . Exposure to aluminum causes health problems. I learned that many years ago (about 1944) from Mr. Stern, my chemistry teacher. Aluminum salts from aluminum cookware can leach from the pot into the food being cooked in them, especially if the food is acidic. . The same prohibitions apply to cooking with aluminum foil. If you must use it to cook with, make a tent so the foil does not come in contact with the food. . Aluminum cookware is prohibited for sale in many European countries. It’s permitted in the United States because good aluminum cookware sold today is anodized (a process that seals the aluminum by changing it’s molecular structure. . Avoid cookware covered with a non-stick coating.

- Q: Can aluminum coils be used in the production of automotive parts?

- Yes, aluminum coils can be used in the production of automotive parts. Aluminum is a lightweight and highly malleable metal, making it an ideal material for manufacturing various automotive components. Aluminum coils can be used to create parts such as body panels, hoods, fenders, doors, and even engine components. The use of aluminum in the automotive industry offers several advantages, including improved fuel efficiency, better performance, and reduced vehicle weight. Additionally, aluminum coils are easy to work with and can be formed into complex shapes, allowing for greater design flexibility in automotive part production. Overall, the use of aluminum coils in the production of automotive parts is common and has become increasingly popular in recent years.

Send your message to us

Terra Bronze Aluminum Coil - Alloy Embossed Aluminum Plate/Sheet 1050 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords