1060/1050 Aluminium Coil for Transformer/ Electronic Components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1060/1050 Aluminium Coil for Transformer/ Electronic Components

l Product Introduction

It is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

1. Temper: O-H112

2. Thickness: 0.15-10mm

3. Width: 30-2200mm

4. Type: Coil/Roll

5. Surface Treatment: mill finished

6. Application: Decoration, packaging, printing, covering, electronic

7. Standard size: Upon customer's demand

8. Quantity: 18tons(±10%)in one 20 feet container

l Product Description

1060/1050 Aluminium Coil for Transformer/ Electronic Components | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050,1060,1070, | O,F, H12, 114,H18,H22, H24,H26,H32, H34,H36,H111, | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55Packaging detail: Standard seaworthy exporting carton, Wooden | |||

l Packaging & Delivery

Packaging detail: pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: within 30 days after we get your 30% deposit or L/C

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

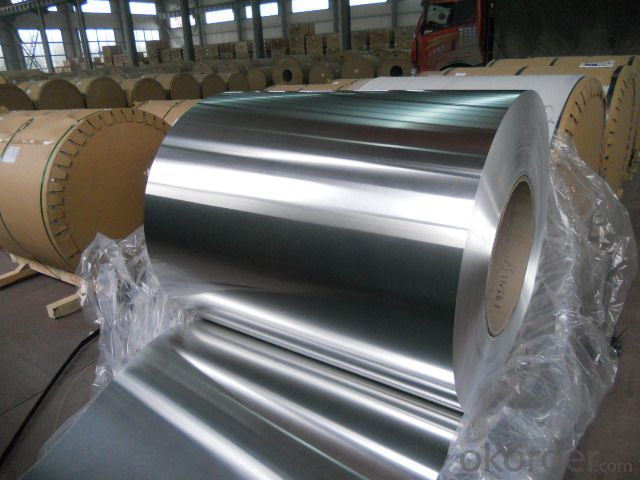

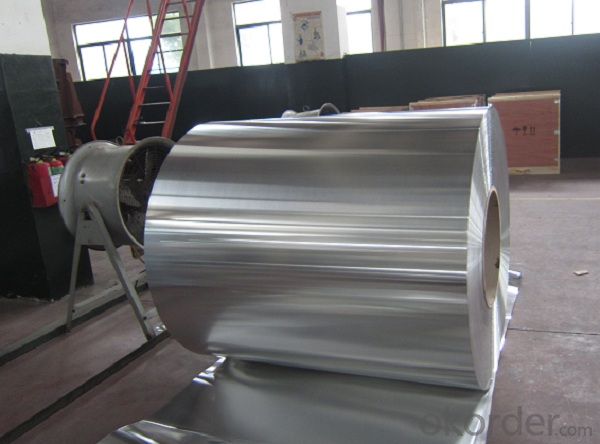

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:How do aluminum coils contribute to improved indoor air quality?

- Aluminum coils contribute to improved indoor air quality by efficiently removing heat and moisture from the air, preventing the growth of mold and mildew. Additionally, aluminum coils are resistant to corrosion, reducing the risk of air contamination caused by rust or other harmful particles.

- Q:What are the potential applications of brushed aluminum coils?

- Brushed aluminum coils possess a wide range of potential applications across diverse industries. Their unique brushed finish renders them an appealing choice for both aesthetic and functional purposes. Below are a few potential applications: 1. Architectural applications: Brushed aluminum coils find use in architectural projects, including building facades, interior wall cladding, and decorative elements. The sleek and modern appearance of the brushed finish enhances the overall design of structures. 2. Automotive industry: The automotive industry can employ brushed aluminum coils for various purposes. These coils can be utilized for interior trim, such as dashboard panels, door handles, and decorative accents, adding a touch of luxury to vehicle interiors. 3. Electronics and appliances: In the manufacturing of electronic devices and appliances, brushed aluminum coils are commonly used. They are employed for producing laptop casings, smartphone covers, and household appliances like refrigerators, ovens, and microwave panels. The brushed finish offers a stylish and durable surface. 4. Signage and displays: Brushed aluminum coils are frequently utilized in signage and display applications. They can be employed to create outdoor and indoor signs, channel letters, and exhibition displays. The brushed finish imparts a professional and attention-grabbing appearance to these signs. 5. Furniture and interior design: The furniture industry can make use of brushed aluminum coils for various purposes. These coils are commonly employed in creating furniture pieces such as tables, chairs, and cabinets. The brushed finish adds a contemporary and sophisticated touch to furniture design. 6. Packaging industry: Brushed aluminum coils can also find applications in the packaging industry. They can be used for packaging high-end products like perfumes, cosmetics, and premium food items. The brushed finish lends the packaging a premium and luxurious appearance. 7. Industrial applications: These coils can be employed in diverse industrial applications, including manufacturing equipment, machinery, and industrial tools. The brushed finish offers durability, corrosion resistance, and a professional appearance. In conclusion, the potential applications of brushed aluminum coils are vast and varied. Their versatility, durability, and aesthetic appeal make them a popular choice in multiple industries, encompassing architecture, automotive, electronics, furniture, packaging, and industrial sectors.

- Q:Classification of aluminium rolls for aluminium rolls

- To spare, so in order to cope with the development of science and technology, in order to contain other aluminum alloy elements, the International Federation of special aluminum strip showed that 9000 series of alternate series, waiting for a new product to fill the gaps of the 9000 series.

- Q:How are aluminum coils measured and specified?

- Aluminum coils are measured and specified based on several key factors. The first aspect is the thickness of the coil, which is typically measured in gauge or millimeters. The thickness determines the strength and durability of the coil, with thicker coils being more robust. Another important specification is the width of the coil, which is usually measured in inches or millimeters. The width determines the size and coverage area of the coil, with wider coils offering greater coverage. The length of the coil is also a crucial specification. It is typically measured in feet or meters and determines the amount of material available for a specific project. Longer coils are often preferred as they minimize the number of joints required during installation. Additionally, the alloy and temper of the aluminum used in the coil are specified. Different alloys have varying mechanical and chemical properties, making them suitable for different applications. The temper refers to the heat treatment process applied to the aluminum, affecting its hardness and flexibility. Coil weight is another important consideration. It is typically measured in pounds or kilograms and determines the handling and transportation requirements for the coil. Lastly, the surface finish of the coil is specified. Common finishes include mill finish, which is untreated, and coated finishes such as painted or anodized. The surface finish affects the appearance and corrosion resistance of the coil. Overall, the measurement and specification of aluminum coils involve factors like thickness, width, length, alloy, temper, weight, and surface finish. These specifications help ensure that the coils meet the desired requirements for various applications.

- Q:What are the common applications of aluminum coils in the aerospace industry?

- Aluminum coils are commonly used in the aerospace industry for various applications such as constructing aircraft frames, manufacturing wings, building fuselages, and designing engine components. The lightweight yet strong nature of aluminum makes it an ideal choice for these purposes, as it helps reduce overall aircraft weight, enhance fuel efficiency, and improve performance. Additionally, aluminum's corrosion resistance properties play a crucial role in ensuring the longevity and durability of aerospace structures.

- Q:Are aluminum coils suitable for architectural louvers?

- Yes, aluminum coils are suitable for architectural louvers. Aluminum is a popular choice for louvers due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. Aluminum coils can be easily formed and fabricated into various shapes and sizes, making them ideal for creating aesthetically pleasing and functional louvers. Additionally, aluminum's durability ensures that the louvers can withstand harsh weather conditions and maintain their structural integrity over time. Overall, aluminum coils are a reliable and versatile material for architectural louvers.

- Q:How do aluminum coils compare to ceramic coils in terms of thermal conductivity?

- Aluminum coils have significantly higher thermal conductivity compared to ceramic coils.

- Q:I am a college student living in a private apartment and I use up lots of aluminium foils to cook and eat. I use aluminium foils as plates because I am too lazy to clean plates. I want to know how environment-unfriendly i am for doing so. How bad am I compared to the guy who keeps on drinking from cans without recycling them?

- Aluminium foil is less than 0.2mm thick but typically 0.02mm so a piece 300mm x 100mm has a total volume of 3 x 1 x 2 x 10^2 mm^3 that is 600 mm^3 The density of Al is 2700 kg/m^3 so the mass of your foil is 2700 x 600 /10^9 kg = 0.00162 kg = 1.62 g Modern aluminium cans weigh about 15g I take it you aren't studying either physics or mathematics or you would easily have workd it out!

- Q:Can aluminum coils be embossed or textured?

- Yes, aluminum coils can be embossed or textured. Embossing or texturing involves the process of creating patterns or designs on the surface of the aluminum coil. This can be done through various methods such as mechanical or chemical processes. The embossed or textured surface adds aesthetic appeal and can also improve the functionality of the aluminum coil, such as enhancing its grip or reducing glare. These embossed or textured aluminum coils find applications in various industries such as construction, automotive, and packaging.

- Q:How would our life on planet earth be modified if there was no aluminum at all? Examples welcomed.

- Heavier. Technology would progress a lot slower because much of the stuff we take for granted is made possible by strong yet light materials such as aluminum.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1060/1050 Aluminium Coil for Transformer/ Electronic Components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords