ABRASIVE SCREEN P60-P400

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coated Abrasives

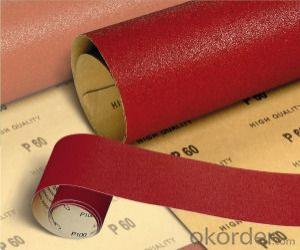

abrasive papera,abrasive cloth,emery cloth

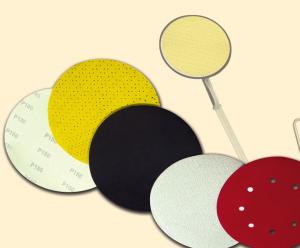

abrasive sand disc,fribe disc

abrasive paper roll,abrasive roll

The manufacture of coated abrasives is performed by a combination of three basic raw materials:

(1) a mineral

(2) a backing on which to put the mineral

(3) an adhesive bond used to hold the mineral to the backing.

A great variety of coated abrasive products may result from the many variations of combining these three raw materials. In order to select the abrasive product which will give you the best results at the least expense, the following background information on the three basic raw materials will be very helpful.

I. COATED ABRASIVES - MINERALS

There are six basic minerals used in the manufacture of coated abrasives. These six fall into two general classifications:

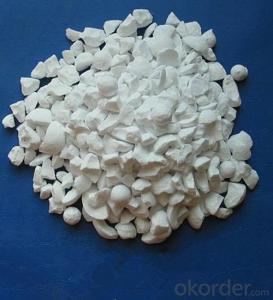

Aluminum Oxide - is brown in color. This synthetic material is extremely tough and is characterized by enormous penetrating strength, even at high speeds. Aluminum oxide has the greatest variety of uses among the coated abrasive minerals. It is the toughest of the grains and its toughness gives long life while its sharpness delivers a fast cut. It is recommended for most of the metal finishing applications.

Silicon Carbide - is shiny black in color. It is very sharp, practically as hard as diamond, and brittle. It fractures into new cutting points during use. It is best suited for very hard or very soft materials. It is preferred for titanium, rubber, leather and similar materials and for finishing and rubbing .lacquers and enamels. It is also well suited for hard plastics.

Flint - is actually quartz. It is white in color, and used commonly by the home craftsman.

Emery - is dull black in color. It is a very hard grit and round in shape. Used widely for polishing. This is a natural form of Aluminum Oxide.

Garnet - is a reddish brown abrasive. Due to its medium hardness and relative sharpness, it is widely used in the woodworking industries.

Mineral Grading Grits: There are a total of twenty-two different grain particle sizes (grits) ranging from No. 12 (the coarsest) to No. 600 (the finest). The grit comparison chart will show the breakdown of these grits.

2. COATED ABRASIVES - BACKINGS

The backings used in the manufacturing of coated abrasive products are classified into four basic groups: 1) Cloth, 2) Paper, 3) Fiber and 4) Combination. These four backings are further subdivided as follows:

1. Cloth

"J" Weight (Jeans)- light weight and flexible - used mostly for finishing and fine polishing.

"X" Weight (Drills) - heavier, more durable and stronger than '"J" weight - recommended for medium and heavy-duty work.

"Y"weight

2. Paper

"A" Weight - lightest and most flexible of the papers - used primarily for finishing operations.

"C" and "D" Weights - intermediate weights which are stronger but less flexible - used for hand sanding and for oscillating machine sanding.

"E" Weight - strongest, most durable and least flexible. Has the most resistance to tear and is used primarily for mechanical sanding.

3. Fiber - made from impregnated paper which has been condensed and hardened. Fiber is tough, strong, hard and able to withstand heat used for discs and drum sanding.

4. Combination

Paper and Cloth laminated together and used on high speed drum sanders and for floor sanding.

Fiber and Cloth laminated together and used for discs.

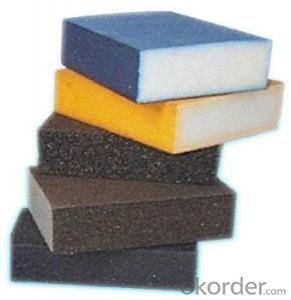

3. COATED ABRASIVES - ADHESIVE BONDS

The third basic raw material used in the manufacture of coated abrasives is the bond. There are two layers of adhesives that anchor and lock the mineral to the backing. The first layer of adhesive is applied to the cloth then the abrasive is applied to that layer and locked on with a top layer of adhesive. There are basically five types of bonds used.

1) Glue -

2) Glue and Filler -

3) Resin over Glue -

4) Resin over Resin -

5) Waterproof -

Send your message to us

ABRASIVE SCREEN P60-P400

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords