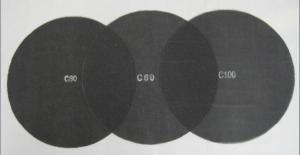

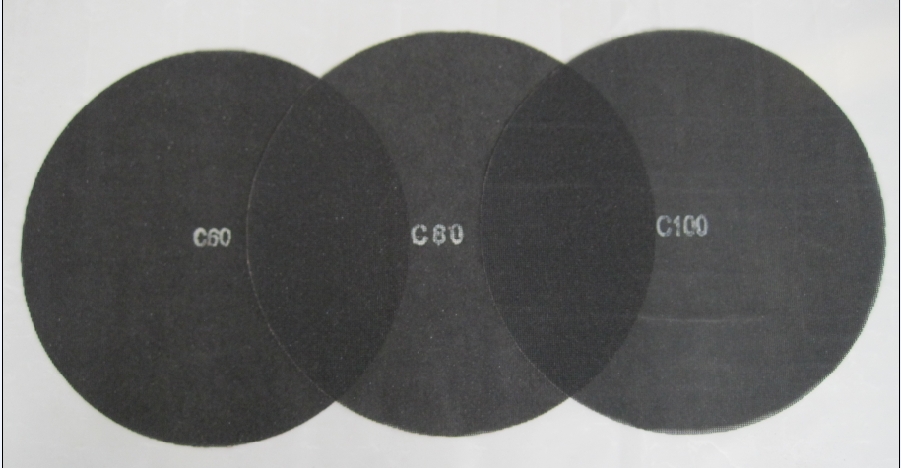

Abrasive screen —C100#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: How limestone mining

- After the grinding of the limestone by the belt conveyor into the vibration sieve for screening, screening of several different sizes, different specifications of limestone, to meet the size requirements of limestone from the finished belt conveyor to the finished material pile;

- Q: Can steel tube couplers be used in conjunction with other scaffolding accessories?

- Yes, steel tube couplers can be used in conjunction with other scaffolding accessories. Steel tube couplers are commonly used in scaffolding systems to connect steel tubes together, providing a secure and stable structure. These couplers are versatile and can be used in combination with various scaffolding accessories such as scaffold planks, diagonal braces, toe boards, and guardrails. They allow for the attachment of these accessories to the scaffolding structure, enhancing safety and functionality. It is important to ensure that the couplers and accessories are compatible and properly installed according to the manufacturer's instructions and industry standards to maintain the integrity and stability of the scaffolding system.

- Q: What is the block of the external wall of the frame structure?

- Are generally inflatable block, light weight, insulation, heat insulation. Can not load. Generally above the gap to stay 30CM

- Q: The following table lists the cooking criteria for several types of wood,

- After drying moisture content is generally required in 8% to 12% is appropriate, thin wood drying equipment with continuous operation of the drum dryer and belt dryer

- Q: Can steel props be used for temporary support in underground structures?

- Yes, steel props can be used for temporary support in underground structures. Steel props are strong and durable, making them suitable for providing support during construction or maintenance work in underground environments. They can effectively bear the load and provide stability to the structure until permanent supports are installed.

- Q: External wall insulation is a mesh cloth or metal mesh?

- External wall insulation is not suitable for grid cloth, mesh cloth or metal mesh for different media walls

- Q: How do geogrids help in soil reinforcement in earthwork projects?

- Geogrids help in soil reinforcement by providing additional strength and stability to the soil in earthwork projects. They are made of high-strength materials, such as polyester or polypropylene, and are placed within the soil layers to distribute the applied loads more evenly. This helps to control and minimize soil movement, preventing erosion, and improving overall stability. Geogrids also enhance the bearing capacity of the soil, allowing for the construction of structures on weak or unstable ground.

- Q: What kind of projects can geotextile and geomembrane be used in?

- Civil engineerings. They can be used in projects of seepage control of the landfills, sewage works, landscape lakes, urban roads and of maintenance and of landscape, etc.. Water conservancy engineerings. They can be used in the projects of seepage control of artificial lakes, reservoirs, canals, dams, etc. Highway and railway constructions. They can be used in the projects of tunnel seepage control, road maintenance, railway construction and slope protection, etc.

- Q: To design a house in the wild, ready to use the fireplace heating, I heard that the fireplace to design a separate fire, please professional advice. More

- Upstairs right, burning wood fireplace is the use of indoor air

- Q: How to buy wall clothing

- But also look at the price is almost far away, imitation is imitation goods in all aspects in order to reduce costs with some inferior things instead, the real wall of the fiber used can be made directly into the fabric, no taste completely environmentally friendly,

Send your message to us

Abrasive screen —C100#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords