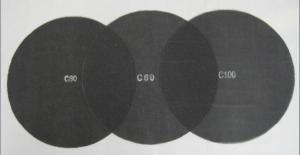

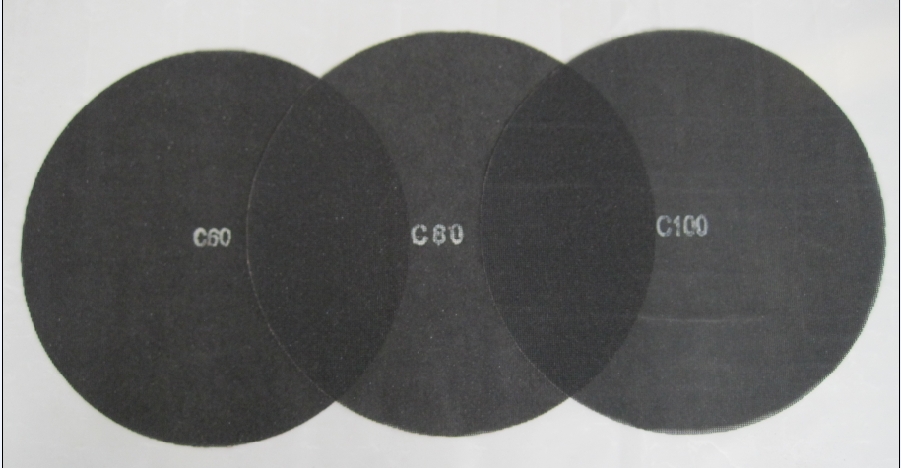

Abrasive screen —C200#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: When the span of the main girder in steel frame is large, it is necessary to arrange the secondary beam

- The floor of the steel frame, the spacing of the secondary beam to the structure of the board material

- Q: Are steel tube couplers suitable for high-rise construction projects?

- Yes, steel tube couplers are appropriate for high-rise construction projects. The construction industry commonly employs steel tube couplers to connect steel tubes and create a robust and inflexible structure. These couplers provide a dependable and efficient method of joining steel tubes, ensuring a secure connection capable of withstanding the immense loads and stresses experienced in high-rise buildings. Steel tube couplers bring several advantages to high-rise construction projects. Primarily, they offer quick and easy installation, enabling faster construction times and improved project efficiency. This is particularly crucial in high-rise construction, where time is often a critical factor. Additionally, steel tube couplers are versatile and applicable in various contexts, including columns, beams, and bracing systems, making them suitable for different structural elements in a high-rise building. Furthermore, steel tube couplers offer a robust and long-lasting connection. They are designed to endure heavy loads and seismic forces, ensuring the stability and integrity of the structure. This is vital in high-rise construction, where the building must withstand diverse external forces, such as wind and earthquakes. Moreover, steel tube couplers provide flexibility in design and construction. They allow for easier modifications and alterations during the construction process, which can be advantageous in high-rise projects where changes are often necessary due to evolving design or site conditions. In conclusion, steel tube couplers are a trustworthy and suitable option for high-rise construction projects. They offer speedy installation, sturdy connections, and design flexibility, making them an ideal solution for constructing secure and resilient high-rise buildings.

- Q: I have a very small bathroom off of my master bedroom. It has black ceramic floor and I don't like it. Can ceramic be painted? If not, is there any way to go over it without tearing it all out?

- Use floor leveling compound to smooth it out and put down self stick floor tile. I have done this twice now in two different houses with great success.

- Q: Can steel formwork be used for both straight and curved walls?

- Yes, steel formwork can be used for both straight and curved walls.

- Q: Do billboards facade can only be combined with angle iron and aluminum-plastic panels do

- Angle steel commonly known as angle iron, is perpendicular to each other on both sides of the long strip of steel. There are equilateral angle and unequal angle. The equal length of the equilateral angle is equal.

- Q: Multilayer board and plywood difference

- multi-layer board is one of the commonly used materials processing enterprises, is a wood-based panel

- Q: In general, the thickness of the solid wood composite floor for how much

- The thickness of the parquet is generally 12 mm and 15 mm (the cost is slightly higher, the foot feel slightly better, the price is slightly expensive), these are the normal specifications: First, the main advantages of solid wood flooring, the surface selection of fine trees In addition to the above mentioned grade, is to emphasize its stability; because of his special structure, the general for more than 7 layers, the use of criss-cross the bonding mode , So easy to deformation, while for geothermal is also a very good choice; Second, the solid wood flooring in accordance with the structure can be divided into two, one for the three solid wood (three: the surface of 3-5 mm hard wood layer) One for the multi-layer solid wood (surface of 0.3-0.5 mm of precious wood veneer, the other more than 7 layers for the criss-crossing mixed wood).

- Q: If a mineral lab at a university carries amphibole (asbestos), isn't that a major health hazard? Why would students be allowed to handle samples without precautions, figuring out the Mohs scale number etc. for this mineral?

- no because amphibole is not asbestos it is a completely different mineral with completely different properties

- Q: The washbasin is not on the marble and is glued to the marble. Is the upper edge of the washbasin and the marble along the edge of the sticky

- Now OKorder are using silicone, Dow Corning silicone is the best, black, white, transparent,

- Q: How does steel frame formwork contribute to the speed and efficiency of construction?

- Steel frame formwork contributes to the speed and efficiency of construction in several ways. Firstly, steel is a highly durable and strong material, allowing for the construction of robust formwork systems that can withstand the pressures and loads of the construction process. This durability ensures that the formwork can be reused for multiple projects, reducing the need for new formwork to be manufactured for each construction project. Additionally, steel frame formwork is highly adjustable and versatile, allowing for quick and efficient assembly and disassembly. The modular design of steel frame formwork enables it to be easily customized and adapted to various project requirements and dimensions. This adaptability reduces the time and effort required to set up the formwork, thereby speeding up the construction process. Moreover, steel frame formwork is lightweight, making it easier to handle and transport on the construction site. The lightweight nature of steel formwork reduces the need for heavy machinery, thus saving time and costs associated with machinery operations. Furthermore, steel frame formwork offers a smooth and even surface finish, resulting in high-quality concrete structures. This eliminates the need for additional finishing work, such as plastering or rendering, saving both time and resources. Lastly, steel frame formwork is highly resistant to moisture and weather conditions, ensuring its longevity and durability. This resistance reduces the need for constant maintenance and repairs, leading to increased efficiency and cost savings in the long run. In conclusion, steel frame formwork contributes to the speed and efficiency of construction through its durability, adaptability, lightweight nature, smooth surface finish, and resistance to moisture. These factors combine to reduce construction time and costs, ultimately enhancing the overall efficiency of the construction process.

Send your message to us

Abrasive screen —C200#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords