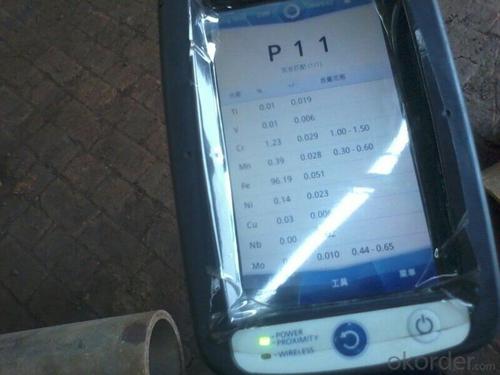

A335P11 alloy tube

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

P11 alloy tube can be recycled 100%, in line with the national strategy of environmental protection and energy conservation, conservation of resources, the national policy to encourage the expansion of the application fields of P11 alloy high-pressure pipe.

P11 alloy steel pipe is placed in the metal blank cold extrusion die cavity, at room temperature, through the press fixed punch pressure is applied to the blank, processing method to produce plastic deformation of P11 alloy steel pipe made of parts.

[1] extruded P11 alloy steel pipe size accurate smooth surface: at present our country in the development of P11 alloy steel pipe generally size precision can reach 8 ~ 9

Level, long degrees generally reach, if the lubrication can reach by ideal (refers to pure aluminum and copper parts), second only to the polishing surface. Therefore made of P11 alloy steel pipe method of parts, generally do not need to re processing, a small amount of just finishing (grinding).

[2] to save raw materials: P11 alloy steel material utilization rate is usually can reach more than 80%. Such as Jiefang automobile piston pin dynamic cutting material utilization rate is 43.3%, while the use of cold extrusion material utilization rate increased to 92%; and as the universal joint bearing sleeve to cold extrusion, the material utilization rate increased from 27.8% to 64% in the past. Visible, by cold extrusion method for producing machine parts, and can save a lot of steel and non-ferrous metal materials.

[3] high productivity: the efficiency of extrusion production machinery parts P11 alloy steel pipe by the method of cold is very high, especially the mass production of parts with cold extrusion steel tube production method, P11 alloy than cutting increased several times, dozens of times, even hundreds of times. For example, automobile piston pin cold extrusion method for manufacturing improved 3.2 times than by cutting, with current and piston pin cold extrusion automata, to further improve productivity. The productivity of a cold extrusion automata productivity is equivalent to 100 ordinary lathe or 10 sets of four spindle automatic lathe.

[4] can process the complex shape parts: such as profiled, inner gear, profiled hole and blind hole, the P11 alloy steel pipe is used in other processing method is difficult to finish, with cold extrusion processing is very convenient. As shown in the parts, convenient extrusion.

[5] the cold extrusion of P11 alloy steel high strength, good rigidity and light weight: because the cold extrusion adopts metal material cold deformation hardening of cold extrusion characteristics, namely the metal blank in three to the compressive stress state, the deformed materials, and has dense microstructure fiber flow continuous, so the parts strength greatly to improve the. So that it can use low strength material instead of high strength materials. For example, in the past 20Cr steel by machining manufacturing Jiefang piston pin, now changed to 20 steel by manufacturing piston pin cold extrusion, the determination of the indexes of performance, higher than the machining method of manufacturing piston pin cold extrusion of P11 alloy steel tube method.

Conclusion

Comparison of various processing methods, has outstanding advantages in cold extrusion of P11 alloy steel pipe technology and project. It is cold extrusion machining, forging, instead of casting and drawing process to produce machine parts, has opened up a broad road.

The 1 seamless steel tube

Because of the different manufacturing processes, divided into hot-rolled (extrusion) seamless steel pipe seamless steel pipe cold drawing (rolling) and two. Cold drawing (rolling) tube is divided into a circular tube shaped tube two.

Overview of A. process

Hot-rolled (extrusion seamless pipe): billet, heating, perforation, three roll cross rolling, rolling or extrusion, tube off, sizing pipe (or reducing), cooling, the blank pipe, straightening, water pressure test (or testing), marking, storage.

Cold drawing (rolling) seamless steel pipe: round tube billet, heating, perforation, heading, annealing, pickling, oiling (copper) and multi pass drawing (Leng Zha), the blank pipe, heat treatment, straightening, water pressure test (testing), marking, storage.

B. seamless steel tube, because of their different purposes is divided into the following several varieties:

GB/T8162-2008 (seamless steel tube structure). Mainly used for general structure and mechanical structure. The representative of material (grade): carbon steel 20, 45 steel; alloy steel Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo etc..

GB/T8163-2008 (fluid with seamless steel pipe). Mainly used for conveying fluid pipeline engineering and large equipment. Representative of material (grade) 20, Q345.

GB3087-2008 (seamless steel tubes for low and medium pressure boiler). Mainly used for industrial boilers and boiler life conveying low pressure fluid pipeline. The representative material for 10, 20 steel.

GB5310-2008 (high pressure boiler seamless pipe). Mainly used in power stations and nuclear power plant boiler high temperature, high pressure fluid delivery set box and pipe. Representative of 20G, 12Cr1MoVG, 15CrMoG etc..

GB5312-1999 (carbon steel and carbon manganese steel seamless steel tube for ship). Mainly used for ship boiler and Superheater I, II grade pressure pipe, etc.. The representative material for 360, 410, 460 grade steel etc..

GB6479-2000 (seamless steel tubes for high-pressure chemical fertilizer equipment). Mainly used for conveying fluid of high temperature and high pressure pipeline of chemical fertilizer equipment. Representative of the material is 20, 16Mn, 12CrMo, 12Cr2Mo etc..

GB9948-2006 (seamless steel tubes for petroleum cracking). Mainly used for boiler, oil refinery heat exchanger and pipes conveying fluid. The representative material for 20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb etc..

GB18248-2000 (seamless steel tubes for gas cylinders). Mainly used for the production of gas, hydraulic cylinders. The representative of 37Mn, 34Mn2V, 35CrMo etc..

GB/T17396-1998 (hot rolled seamless steel tubes for hydraulic prop). Mainly used in production of coal mine hydraulic support cylinder, column, and other hydraulic cylinder, column. The representative material for 20, 45, 27SiMn.

GB3093-1986 (high pressure seamless steel tubes for diesel engine). Mainly used for diesel engine high pressure oil injection system. The steel pipe is generally drawn tube, the representative of 20A.

GB/T3639-1983 (cold drawn or cold rolled precision seamless steel tube). Mainly used for mechanical structure, carbon pressure equipment used, the requirements of high dimensional accuracy, surface finish

- Q: How are steel pipes protected against electrolytic corrosion?

- Steel pipes are protected against electrolytic corrosion through various methods such as applying protective coatings, using sacrificial anodes, implementing cathodic protection systems, or utilizing corrosion inhibitors. These measures help to prevent the flow of electric current and the subsequent corrosion caused by electrolysis, ensuring the longevity and integrity of the steel pipes.

- Q: How are steel pipes used in natural gas processing plants?

- Steel pipes are used in natural gas processing plants to transport and distribute natural gas from one point to another within the facility. These pipes are capable of withstanding high pressure and temperature, ensuring the safe and efficient flow of the gas throughout the plant. Additionally, steel pipes are resistant to corrosion, which is crucial as natural gas can be corrosive. They are also used for connecting various equipment and components in the processing plant, allowing for the smooth operation of the entire system.

- Q: How are steel pipes used in the construction of stadiums?

- Steel pipes are commonly used in the construction of stadiums for various purposes such as structural support, plumbing, and drainage systems. They provide strength, durability, and flexibility, making them ideal for constructing grandstands, roofs, and other large-scale structures. Additionally, steel pipes are used for installing plumbing systems to supply water for restrooms, concession stands, and irrigation. They also play a crucial role in the drainage system, allowing for efficient removal of rainwater and preventing flooding in the stadium. Overall, steel pipes are essential components in stadium construction due to their versatility and reliability.

- Q: Can steel pipes be used for gas lines?

- Yes, steel pipes can be used for gas lines. Steel pipes are commonly used for gas lines due to their durability, strength, and resistance to extreme temperatures. They are able to withstand high pressure and are typically coated with corrosion-resistant materials to ensure the safety and longevity of the gas line system.

- Q: What are the common applications of steel pipes in industrial settings?

- Steel pipes are commonly used in industrial settings for various applications such as transporting fluids and gases, providing structural support in construction projects, conveying materials in manufacturing processes, and facilitating the distribution of water, oil, and gas in pipelines.

- Q: How are steel pipes used in the construction of irrigation systems?

- Steel pipes are commonly used in the construction of irrigation systems due to their strength and durability. These pipes are used to transport water from a water source, such as a well or reservoir, to the desired areas for irrigation. They are often used in underground or above-ground applications, providing a reliable and efficient means of delivering water to crops or plants. Steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for irrigation systems that require long-term functionality.

- Q: What is the hardness of steel pipes?

- The hardness of steel pipes varies depending on the specific grade and manufacturing process used. However, steel pipes are generally known for their high hardness and durability, as they are often designed to withstand heavy loads, abrasive environments, and high-pressure conditions.

- Q: What are the environmental impacts of using steel pipes?

- The environmental impacts of using steel pipes include the extraction and processing of raw materials, such as iron ore and coal, which contribute to deforestation, habitat destruction, and greenhouse gas emissions. The manufacturing process also generates significant amounts of waste, including slag and emissions from steel production. The transportation and installation of steel pipes contribute to carbon emissions, while their corrosion and maintenance may result in the release of toxic substances into the environment. Proper waste management and implementing sustainable practices can help mitigate some of these impacts.

- Q: Can steel pipes be used for conveying abrasive slurries?

- Indeed, abrasive slurries can be effectively conveyed through steel pipes. The remarkable durability and strength of steel pipes render them highly suitable for the transportation of abrasive substances like slurries. Nevertheless, to guarantee prolonged service life and avert excessive deterioration, it is crucial to carefully choose the right grade of steel and take into account factors such as pipe thickness, lining choices, and flow velocity. Furthermore, the implementation of adequate maintenance and inspection protocols can play a pivotal role in promptly identifying and resolving any wear or corrosion issues that may arise with time.

- Q: Can steel pipes be bent or shaped to meet specific requirements?

- Yes, steel pipes can be bent or shaped to meet specific requirements through various techniques such as hot bending, cold bending, or using specialized machinery like pipe benders.

Send your message to us

A335P11 alloy tube

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords