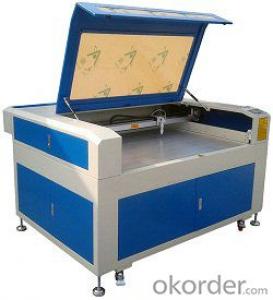

9KW Minitype Fiber Laser Cleaning Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Laser cleaning technology refers to the use of high-power density laser beams to irradiate the surface of the work piece, so that the dirt, rust or coating on the surface will be evaporated or peeled off instantly, thereby achieving a clean process. This cleaning equipment is a new generation of surface treatment high-tech products, easy to install, operate and realize automation. Simple operation, no chemical reagents, no media, no dust, no water can be cleaned when the power is turned on, and it can remove the surface of the object, paint, stains, dirt, rust, coating, etc.

Technical Parameter :

Name | Fiber Laser Cleaning Machine |

Wavelength range of laser | 10-80mm |

Power adjustable range | 10-100% |

Output cable length | 10 meters |

Repetition rate adjustable range (KHZ) | 20-50KHz (gradual and adjustable) |

Power (RR=50KHz Pmax) | ≥200W |

Max bear power | 2.8KW |

Power supply | Uniphase 220V±10% 50/60Hz |

Operating ambient temperature | 0℃~40℃ |

Operating ambient humidity | ≤80%RH |

Dimensions (L×W×H) | 1150*870*1140mm |

Power cord length | 5 meters |

Total power | 9KW |

Configuration:

No. | Name | Quantity | Branch | Comment |

Mechanical part | ||||

1 | Control cabinet

| 1set | SENFENG | |

2 | Cooling system | 1set | Standard | Water cooling machine |

Electrical part | ||||

3 | Electric components | 1 set | Schneider/Honeywell

| Schneider/Honeywell

|

4 | Cleaning system | 1 set | Raycus | Raycus |

Optical part | ||||

5 | Laser source | 1set | Raycus | Other brand customized |

6 | Cleaning head | 1set | Raycus | Raycus |

Documents | ||||

7 | Maintenance tool (protective goggles are included) | 1set | SENFENG | Ensure the daily maintenance of machine

|

8 | Instructions manual | 1 copy | SENFENG | Updated based on changes of machine |

9 | Certificate of conformity | 1set | SENFENG | Complies with national standard

|

Advantages of fiber laser cleaning

1.The electronic control part is highly integrated, effectively saving space

2.Dedicated laser cleaning host control system, with clear and concise interface, convenient operation, various parameters can be set and adjusted according to application cases, so as to achieve high-performance control of laser and galvanometer;

3.High-performance laser galvanometer, fast scanning speed, high precision, combined with professional control system, to meet various laser cleaning application requirements;

4.The hand-held part has a simple and light structure, ergonomic design, easy to operate, and can be used with a manipulator to realize automatic cleaning;

5.The laser cleaning system is stable and convenient after-sales. There is almost no need for tedious maintenance and Repair

Comparison of fiber laser cleaning and traditional cleaning methods

Items | Fiber laser cleaning | Chemical cleaning | Mechanical grinding | Dry ice cleaning | Ultrasonic cleaning |

Cleaning method | Laser; Non-touchable | Chemical detergent; Touchable | Sand paper; Touchable | Dry ice; Non-touchable | Detergent; Touchable |

Damage to Work piece | No | Yes | Yes | No | No |

Cleaning efficiency | High | Low | Low | Middle | Middle |

Consumption | Electricity only | Chemical detergent | Sand paper; grinding wheel,etc | Dry ice | Special detergent |

Precise cleaning | High precision | Low precision | Low precision | Low precision | Cleaning range can not be designated |

Safety/environment friendly | No pollution | Chemical pollution | Environmental pollution | No pollution | No pollution |

Cost | No consumables, low maintenance costs | Initial investment is low, Consumables cost is extra high

| Initial investment is high, consumables cost is low | Initial investment is middle, consumables cost is high | Initial investment is low, consumables cost is middle |

- Q: Which industries need laser equipment?

- To buy laser equipment, you can go to the mainland star credit mall look

- Q: What brand of 3D laser cutting equipment, robot and laser brand also help recommend

- I saw the manipulator of Wuhan gold Zhizhuo > < laser cutting machine in the exhibition, technology should be more mature, the cost is not very expensive.

- Q: Laser equipment since it can cut thick steel plate, if accidentally hit the laser in the human body, will not cause people to cut the safety of the accident?

- ll, only a few milliwatts but looks brightness is very strong. In the experiment, the project operation not careless, must be safe the first general. High power laser cutter is very well protected,

- Q: How much is the cheapest equipment for the Eurostar fotona in Germany?

- Otona Eurostar laser, founded in 1964, is the world's oldest laser multinational.

- Q: How about Wuhan Tianqi laser equipment manufacturing Co. Ltd. staff evaluation

- , listening to the old employees on wages special slow, but you are able to engage in the relationship that is fine

- Q: A Italy Puruima laser cutting equipment price is how much?

- Laser power? Machine model?

- Q: Just interviewed two sales jobs. One is to do in Shenzhen Huaqiang North electronic components sales, one is Shenzhen laser equipment sales

- If the laser equipment is basically a one-time sale, but there is no consumables, up to one or two years after the change of parts, and the risk is very big, because the clerk received orders have to bear the risk for this order, if it is in a strong company, to be considered, because the laser equipment is

- Q: Equipment requirements for laser dancing

- The steel frame structure, mainly to the surface of the stage solid, tempered glass, a dancer to bear weight, and can withstand various range of motion produced by pressure Google culture after the development and improvement stag

- Q: What is the main technology of Zhongshan flying dragon Hardware Technology Co., Ltd.?

- From the industrial and commercial registration information see his business scope: research and development, production

- Q: Which is the best effect of laser beauty equipment and radio frequency beauty equipment?

- Now the most advanced and most effective is radio frequency beauty technology, safe and without side effects

Send your message to us

9KW Minitype Fiber Laser Cleaning Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords