Aluminum Trailer Sheets - 7075 T6 T651 Aluminum Sheet for Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

7075 T6 T651 Aluminum Sheet for Moulding

l Production Introduction

Chemical data:

| Silicon (Si) | Iron | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc | Titanium |

| (Fe) | (Zn) | (Ti) | |||||

| 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.20 |

| Aluminum Type / Temper | Minimum Tensile Strength (ksi) | Minimum Yield Strength (0.2%, ksi) |

| 7075 Aluminum Alloy | ||

| -T6 | 83 | 73 |

| -T651 | 83 | 73 |

| 7075 Aluminum Sheet and Plate | ||

| -T6 | 74-78 | 63-69 |

| -T651 | 67-78 | 54-68 |

| 7075 Aluminum Extrusionsc | ||

| -T6 | 78-81 | 68-73 |

| -T6510 | 78-81 | 68-73 |

| -T6511 | 78-81 | 68-73 |

l Packaging & Delivery

Packaging detail: Inner packing: each sheet is covered with PE film or kraft paper;

Outer packing: wooden pallet/case with seaworthy packing or as per customer's requirement.

Delivery detail: 20-25 days

l Company Profile

CNBM, China National Building Material Group Corporation is the largest state owned company under central government of China that deals with building materials and industrial equipment.

Since 1984, we are professional manufacturer of construction machinery and equipment with the brand CMAX. Here I recommend our Aluminium Treadplate to you.

We have our own factory, logistics system, e-business platform, and oversea warehouse. Our products meet international quality standard, with CE certificate.

l CNBM World Wide

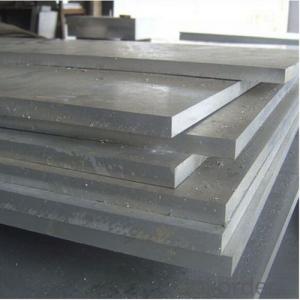

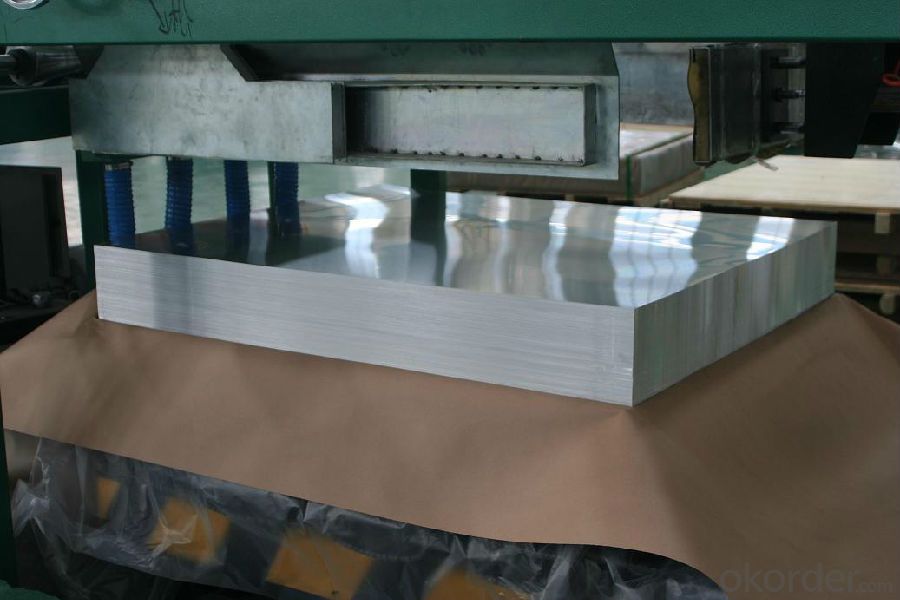

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons per size

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: This question asks for a list of various coatings that can be applied to aluminum sheets for different purposes.

- <p>Aluminum sheets can be coated with a variety of materials to enhance their properties such as durability, appearance, and corrosion resistance. Some common types of coatings include: 1. Anodizing: Creates a protective oxide layer on the aluminum surface. 2. Powder Coating: A dry coating that is electrostatically applied and then cured at high temperatures. 3. PVDF (Polyvinylidene Fluoride) Coating: Known for its excellent resistance to UV, chemicals, and weathering. 4. Epoxy Coating: Provides a hard, durable finish that is resistant to chemicals and corrosion. 5. Polyester Coating: Offers good adhesion and is often used for outdoor applications. 6. Fluorocarbon Coating: Provides a high level of durability and resistance to weathering. 7. Ceramic Coating: A newer type of coating that offers excellent heat resistance and a smooth finish. These coatings are chosen based on the specific requirements of the application, such as architectural, automotive, or aerospace uses.</p>

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are versatile in construction due to their strength, durability, and lightweight properties. They are used for roofing and cladding to provide weather resistance and aesthetic appeal. Aluminum sheets are also utilized in the fabrication of window frames and doors for their strength and thermal efficiency. They are employed in the construction of scaffolding and temporary structures due to their lightweight and ease of assembly. Additionally, aluminum sheets are used in the manufacturing of facades, canopies, and decorative elements for their modern look and low maintenance requirements.</p>

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes. This is typically done through a process called extrusion, where the aluminum sheet is heated and forced through a die to form the desired shape. The extrusion process allows for the creation of seamless tubes or pipes with consistent dimensions and a smooth surface finish. Aluminum is a highly versatile and malleable material, making it suitable for various applications where lightweight and corrosion-resistant tubing is required.

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Densities: Aluminum: 2,710 kg/m^3 Copper: 8,940 kg/m^3 Basis: 1 m^3 of copper-aluminum alloy mass of aluminum in 1 m^3 alloy = 519 kg vol. of aluminum in the 1 m^3 alloy = 519 kg/(2710 kg/m^3) = 0.1915 m^3 vol. of copper in 1 m^3 alloy = 1 m^3 - 0.1915 m^3 = 0.8085 m^3 mass of copper in 1 m^3 alloy = (0.8085 m^3)*(8,940 kg/m^3) = 7,227.87 kg mass of the m^3 alloy = 7,227.87 kg + 519 kg = 7,746.87 kg %weight of aluminum = (519 kg/7,746.87 kg)*100% = 6.70% The alloy has 6.70% by weight of aluminum in it.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to install and reducing the load on the structure of the building. Secondly, aluminum is highly durable and resistant to corrosion, which means it can withstand harsh weather conditions, such as heavy rain, snow, and UV radiation. Additionally, aluminum is non-combustible, making it a safe choice for roofing. Furthermore, aluminum is an environmentally friendly material as it is 100% recyclable, reducing its impact on the environment. Overall, aluminum sheet is a reliable and efficient option for roofing applications.

- Q: What are the distinctions between standard and custom-made aluminum sheets?

- <p>Standard aluminum sheets are mass-produced with fixed dimensions and specifications, making them readily available and cost-effective. They are suitable for common applications where specific dimensions are not a priority. Custom-made aluminum sheets, on the other hand, are tailored to meet specific requirements regarding size, thickness, and other properties. They offer flexibility for unique applications but may be more expensive and have longer lead times due to the specialized manufacturing process.</p>

- Q: Are aluminum sheets suitable for chemical filtration applications?

- Yes, aluminum sheets are suitable for chemical filtration applications. Aluminum is known for its excellent corrosion resistance and durability, making it a reliable choice for chemical filtration systems. Aluminum sheets can effectively filter out impurities and contaminants in various chemical processes, including separating solids from liquids and removing harmful substances. Additionally, aluminum sheets can withstand high temperatures and pressures, making them suitable for a wide range of chemical filtration applications.

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Aluminum sheets are indeed suitable for the production of aircraft parts. They are a lightweight and durable material commonly utilized in the aerospace sector. With its exceptional strength-to-weight ratio, corrosion resistance, and excellent formability, aluminum is ideal for various applications in aviation. It is effortless to fabricate aluminum sheets into intricate shapes, making them perfect for manufacturing aircraft wings, fuselages, panels, and structural supports. Moreover, aluminum's high conductivity facilitates efficient heat dissipation in crucial areas of the aircraft. Consequently, aluminum sheets are widely preferred for aircraft part manufacturing due to their desirable properties and reliability in the aerospace field.

Send your message to us

Aluminum Trailer Sheets - 7075 T6 T651 Aluminum Sheet for Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords