600MM Z75 Rolled Steel Coil for Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

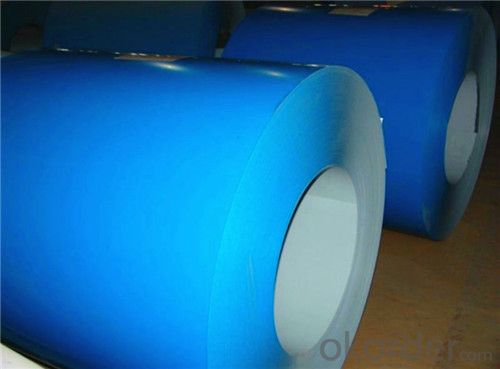

Structure of 600MM Z75 Rolled Steel Coil for Sandwich Panel

Description of 600MM Z75 Rolled Steel Coil for Sandwich Panel

600MM Z75 Rolled Steel Coil for Sandwich Panel is a kind of color steel. With the cold rolled steel or galvanized steel of different strength and hardness and thickness asrequested, it is manufactured through applying Zinc coating on both faces by hot dipped processing. Of the coating, Al accounts for about 55%, Si 1.6%, and Zn is the remaining. And its surface has bright silver color and regular embossed-like figure, which are highly decorative with long life.

Main Feature of 600MM Z75 Rolled Steel Coil for Sandwich Panel

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of 600MM Z75 Rolled Steel Coil for Sandwich Panel

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;pentane tank; road sign; etc.

4.Agriculture:barn other decking; etc.

5.Others:vending machine; game machine; etc.

Specifications of 600MM Z75 Rolled Steel Coil for Sandwich Panel

Product | 600MM Z75 Rolled Steel Coil for Sandwich Panel |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled, slight oiled |

Spangle | Regular spangle , small spangle, zero spangle,mini spangle |

ID | 508MM or 610MM |

Coil weight | 1-25MT MAX |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of 600MM Z75 Rolled Steel Coil for Sandwich Panel

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Our delivery time is around 30 day after order confirmed.

3. How to make sure the quality of the order?

We have our own quality control team with over 40 QC every link from raw material to final product we have strict quality test.

4. What is your payment?

We accept L/C at sight, T/T, L/C 90 days, 60 days, 30 days acceptable

- Q: what do you think about it? Is it a good steel for the money? the knife that i have with that steel is the kershaw chill. good knife for the price

- 8Cr13MoV is a decent blade steel...not a great steel, but about as good as you will generally find without paying much higher prices. It's used by a number of well known knife makers... It's basically equivalent to AUS-8 and will work and hold an edge reasonably well for most basic cutting chores. *************************************** From Wikipedia, the free encyclopedia: 8Cr13MoV, a Chinese stainless steel tempered at the Rc56 to Rc58 range and used in the Tenacious, Persistence, Ambitious, Resilience, Grasshopper, Kiwi3 and Byrd lines of knives. Often compared to AUS-8, but with slightly more Carbon.

- Q: How do steel coils contribute to the manufacturing of appliances?

- Appliances heavily rely on steel coils in their manufacturing process. Typically crafted from high-quality steel, these coils serve various purposes throughout appliance production. To begin with, appliance manufacturers employ steel coils to fabricate essential components. These coils are instrumental in constructing the outer and inner casings of appliances such as refrigerators, washing machines, and dishwashers. The resilient properties of steel ensure durability and safeguard the internal mechanisms of the appliance. Furthermore, steel coils find application in the production of appliance parts. They are often cut, shaped, and transformed into smaller elements such as brackets, frames, and panels. These parts play a crucial role in enabling appliances to function properly and contribute to their overall performance and lifespan. In addition, steel coils significantly contribute to the manufacturing of appliance doors. Molding and shaping the coils allows the creation of sturdy doors, which are vital for the accessibility and safety of the appliance. Steel doors offer strength, security, and insulation, making them an ideal choice for appliances. Moreover, steel coils are utilized in the manufacturing of heating elements and burners for appliances like stoves and ovens. These coils are designed to withstand high temperatures and efficiently transfer heat, ensuring that the appliances can effectively cook or bake food. Overall, steel coils play an integral role in the appliance manufacturing process. They are employed to construct the outer casings, vital components, doors, and heating elements of appliances. The utilization of steel in these applications enhances durability, safety, and overall performance, resulting in more reliable and long-lasting appliances.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Does it say stainless steel on it?

- Q: What does "steel roll number" mean?

- The coil numbers in the steel industry are generally applicable to rolled round steel bars. A coil of steel has a specified length and weight. Different rolls have different volumes

- Q: What are the common tests performed on steel coils for quality assurance?

- There are several common tests performed on steel coils for quality assurance purposes. These tests help ensure that the steel coils meet industry standards and customer requirements. One of the most common tests is the dimensional inspection. This involves measuring the length, width, and thickness of the steel coils to ensure they meet the specified dimensions. Any deviations from the required dimensions can indicate a quality issue. Another important test is the visual inspection. This involves a thorough examination of the steel coils for any defects or surface imperfections such as scratches, dents, or rust. Visual inspection is crucial to identify any visual defects that might affect the performance or appearance of the steel coils. Additionally, mechanical tests are performed to assess the strength and durability of the steel coils. Tensile tests are conducted to measure the maximum amount of force the steel can withstand before breaking. This test helps determine the steel's tensile strength, yield strength, and elongation properties. Another mechanical test commonly performed is the hardness test. It measures the steel's resistance to indentation, which is an indicator of its strength and toughness. Hardness tests are typically conducted using methods such as Rockwell, Brinell, or Vickers. Corrosion resistance is also an important aspect of steel coil quality assurance. This is typically evaluated through tests such as salt spray or humidity tests. These tests simulate harsh environmental conditions to assess the steel's ability to resist corrosion. Lastly, chemical composition analysis is performed to ensure that the steel coils contain the required elements in the specified proportions. This analysis helps verify that the steel meets the desired chemical properties, which can significantly impact its performance and suitability for specific applications. Overall, these common tests performed on steel coils for quality assurance purposes help ensure that the coils comply with industry standards, customer requirements, and are fit for their intended use.

- Q: What kind of insulation should be used in a steel building?

- Fiberglass batts or spray on foam both work well

- Q: How are steel coils used in the production of roofing panels?

- Steel coils are an essential component in the production of roofing panels. These coils, typically made of galvanized or coated steel, serve as the base material for manufacturing durable and high-quality roofing panels. Firstly, the steel coils are processed through a series of machines in a production facility. These machines flatten, clean, and shape the coils into the desired dimensions and profiles for the roofing panels. The process ensures that the steel coils are uniform in thickness and free from any impurities or imperfections that could compromise the integrity of the final product. Once the steel coils are prepared, they are then fed into a roll forming machine. This machine gradually bends and shapes the steel coils into the specific design and size required for the roofing panels. The roll forming process provides the panels with their distinctive corrugated or standing seam profiles, which enhance their strength and ability to withstand various weather conditions. After the roll forming process, the steel coils are cut into individual roofing panels of the desired length. These panels are then further processed to add additional features, such as coatings or finishes, for improved protection against corrosion and aesthetic appeal. The steel coils are often coated with protective layers, such as zinc or paint, to enhance their resistance to rust, UV rays, and other environmental factors. Finally, the roofing panels are packaged and shipped to construction sites or distributors for installation. The use of steel coils in the production of roofing panels ensures that the final product is strong, durable, and long-lasting. Steel is renowned for its high tensile strength, which makes the roofing panels capable of withstanding heavy loads, strong winds, and other external forces. In summary, steel coils play a crucial role in the production of roofing panels. They are transformed into the desired dimensions and profiles through a series of manufacturing processes, ensuring uniformity and quality. The resulting roofing panels are not only aesthetically pleasing but also highly durable, providing superior protection and longevity for buildings.

- Q: What are the benefits of using steel coils in the manufacturing of pipes?

- There are several benefits of using steel coils in the manufacturing of pipes. Firstly, steel coils offer high strength and durability, making them capable of withstanding extreme pressure and temperature conditions. This ensures the longevity and reliability of the pipes. Secondly, steel coils provide excellent corrosion resistance, which is crucial for pipes that come into contact with different substances or are used in corrosive environments. Additionally, steel coils allow for seamless production and fabrication of pipes, resulting in a smooth surface finish and uniform dimensions. Lastly, steel coils are readily available and cost-effective, making them a preferred choice for pipe manufacturing.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Stainless Steel is an allow of Chrome and Steel and several other additives. There are at least 100 types of Stainless.. Most common is 300 Series , that the cheapest and used in household stuff. Then there is the 400 series in that series is a stainless that can be heat treated because it contains sufficient carbon to do so. I would say if its wear you are looking for Stainless is not wear resistant to the extent other steels are. You want a heat treatable oil hardenting steel for that purpose. A good example and an old reliable one is what is called O-1 or oil hardening one. It can be heated with a torch at the wear end and quenched in oil right on the fab site. to a hardness of Rockwell C of about 55 or so and wears well. I suppose the best basket would be a 300 Series stainless to reduce rusting with end pieces that are probably bolted on made of O-1 heat treated to RC of about 55 or so. Of course if you make the wear ends removable with bolts, you can really get some wear steels for those wear parts You can use High Speed Steel RC=95, Drills are high speed steel. and even a material called Hasteloy next to carbide in hardeness. I suspect those baskets are made of Stainless Steel with wear ends of another material as ive discussed above.

Send your message to us

600MM Z75 Rolled Steel Coil for Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords