51crv4 Hot Rolled Spring Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

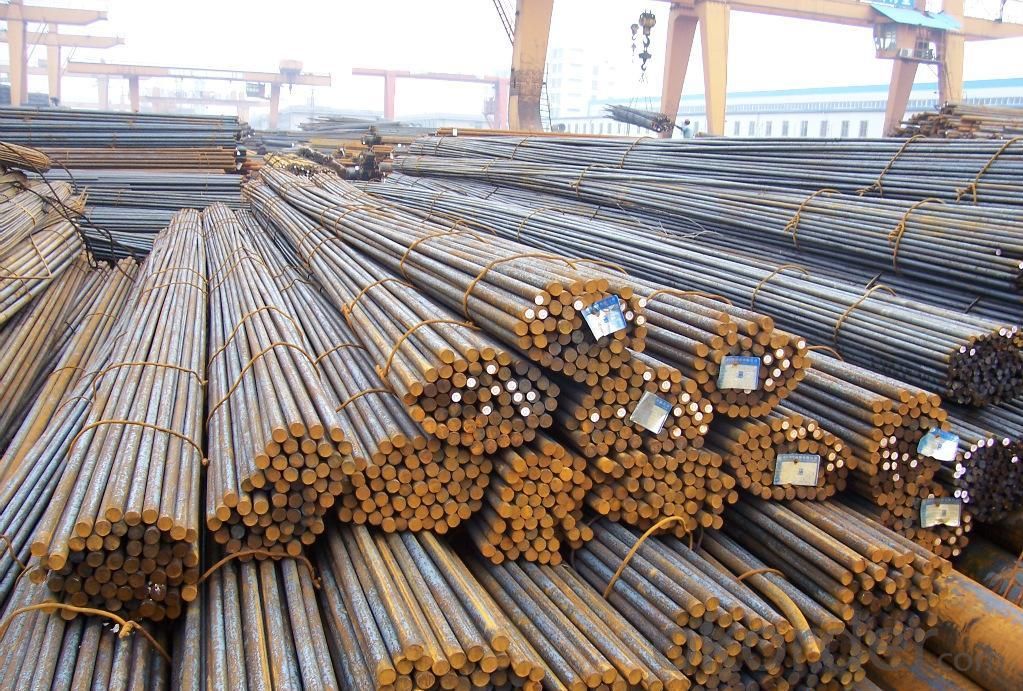

51crv4 Hot Rolled Spring Steel Bar

Product Description:

1: Material: spring steel bar 51crv4.

2: Size: 90x10mm.

3: Length: 5800mm, or as your requirements.

4. Package: In bundles, packed with 5 clamps along the bundles ,including two clamps in 1.5 meters each head, three clamps in the middle of bundle. 20-25 ton for each 20' container, each bundle weight about 2-2.5 tons.

Pls don’t worry about our loading products into containers, we have the forklift truck and loading platform, our packing also meet transport on the ocean.

Specification:

Measurement | Thickness | Width | Length |

6mm~35mm | 40mm~150mm | 4m-8m (customized) | |

Edge(Cross Section) | round edge profile to DIN59145 | Square edge profile to DIN59146 | |

Bundle Weight | Around 2.0 MT | ||

Technique | Hot Rolled | ||

Surface | Grooved | Plain-smoothed | |

Quenchant | Oil/Water | ||

Temper Stressing | 480°C-560°C | ||

Quenching Temprature: | 800°C-1000°C | ||

OEM | Material Composition Offered by Customers | ||

Application | sup9/sup9a/sup10/55Cr3/50CrV4 | Automotive suspension springs | |

sup7/9260/30CrMnB/27CrMnB | Rotary tools Blades; Knife; Swords; | ||

Payment Term | 100% L/C at Sight. | 30% T/T Down Payment, Balance Against B/L Copy. | |

Packing | In bundles. Each bundle packed with 2 steel strips and 3 steel wires. | ||

Application:

WBQ Rolled steel round bar are widely used in machinery making, autombile making, railway, mine machinery, petoleum machinry, agricultural machinery and civil archtectue such as all kinds of shafts, screws, connecting rods, hardware tools, gears, standard parts, spanners fasteners, structural parts for automobile and agricultural machinery, outer and iner sleeves, rollers and balls for bearing making.

Product Show:

- Q: What is the significance of carbon content in special steel?

- The carbon content in special steel is significant because it determines the steel's hardness, strength, and overall performance. Higher carbon content results in increased hardness and strength, making the steel suitable for applications requiring durability and resistance to wear and tear. On the other hand, lower carbon content enhances the steel's ductility and formability, making it more suitable for shaping and molding processes. Therefore, carbon content plays a crucial role in tailoring the properties of special steel to meet specific industrial requirements.

- Q: Can special steel be used in the defense equipment manufacturing industry?

- Yes, special steel can be used in the defense equipment manufacturing industry. Special steel alloys, such as high-strength and corrosion-resistant varieties, are often utilized in the production of various defense equipment components, including armored vehicles, missiles, aircraft, and naval vessels. These specific steel types offer superior mechanical properties, durability, and resistance to extreme conditions, making them highly suitable for defense applications.

- Q: What are the different joining processes for special steel?

- There are various joining processes for special steel, including welding, brazing, and soldering. Welding involves melting the steel and fusing it together, while brazing uses a filler metal with a lower melting point to join the steel parts. Soldering, on the other hand, uses a lower melting point alloy to create a bond between the steel pieces. Each process has its own advantages and limitations, and the choice depends on factors such as the type of steel, the desired strength of the joint, and the application requirements.

- Q: What are the different casting techniques used for special steel?

- Some of the different casting techniques used for special steel include investment casting, sand casting, continuous casting, and centrifugal casting. Each technique has its own advantages and is chosen based on factors such as the complexity of the steel part, the desired quality, and cost considerations.

- Q: Can special steel be used for making electronics components?

- Yes, special steel can be used for making electronics components. Special steel, such as stainless steel, can provide excellent corrosion resistance, durability, and electrical conductivity, making it suitable for various applications in electronics manufacturing.

- Q: What are the different methods of surface ion nitriding for special steel?

- There are several methods of surface ion nitriding for special steel, including traditional gas nitriding, plasma nitriding, and ion nitriding. Each method involves introducing nitrogen ions into the surface of the steel to improve its hardness, wear resistance, and corrosion resistance. Gas nitriding involves exposing the steel to ammonia gas at high temperatures, while plasma nitriding uses a low-pressure plasma to generate nitrogen ions. Ion nitriding, on the other hand, utilizes a high-voltage electrical discharge to create the nitrogen ions. Overall, these methods offer various options for enhancing the surface properties of special steel, depending on the specific requirements and desired outcomes.

- Q: What are the main characteristics of heat-resistant steel?

- The main characteristics of heat-resistant steel include high resistance to oxidation, excellent strength at elevated temperatures, good thermal stability, and the ability to maintain its structural integrity even under extreme heat conditions.

- Q: What are the different surface cleaning methods used for special steel?

- There are several surface cleaning methods that can be used for special steel, depending on the specific requirements and the level of cleanliness desired. Some of the commonly used methods include: 1. Mechanical Cleaning: This method involves the use of abrasive materials or tools to physically remove dirt, rust, and other contaminants from the surface of the steel. It can be done through processes such as sanding, wire brushing, or abrasive blasting. 2. Chemical Cleaning: Chemical cleaning involves the use of chemical agents to dissolve or loosen dirt, grease, oil, or rust from the surface of the steel. Different types of chemicals can be used depending on the type and severity of the contaminants. Acid pickling is one such method that involves immersing the steel in an acid solution to remove scale and rust. 3. High-pressure Water Cleaning: This method utilizes the force of high-pressure water jets to remove dirt, grease, and other contaminants from the surface of the steel. It is effective in removing loose particles and can be used as a pre-cleaning step before other surface preparation methods. 4. Ultrasonic Cleaning: Ultrasonic cleaning is a non-abrasive method that uses high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode upon contact with the surface of the steel, effectively removing contaminants from hard-to-reach areas. 5. Electrochemical Cleaning: This method involves passing an electric current through a cleaning solution or electrolyte to facilitate the removal of contaminants from the steel surface. It is useful in removing rust and restoring the steel's appearance. 6. Thermal Cleaning: Thermal cleaning methods, such as flame cleaning or heat treatment, involve subjecting the steel to high temperatures to burn off organic contaminants or to induce controlled oxidation and subsequent removal of scale, rust, or other surface impurities. It is important to note that the choice of surface cleaning method depends on various factors, including the type of contaminants, the condition of the steel, the desired level of cleanliness, and the overall application requirements. A combination of different methods may be used to achieve the best results.

- Q: What are the properties of corrosion-resistant stainless tool steel?

- Corrosion-resistant stainless tool steel possesses a number of key properties. Firstly, it exhibits excellent resistance to corrosion, making it highly durable and suitable for use in corrosive environments. It also has high strength and hardness, ensuring its effectiveness as a tool material. Additionally, this type of steel offers good wear resistance, enabling it to withstand repeated use without significant deterioration. Moreover, it retains its sharpness and cutting edge for extended periods, making it an ideal choice for various cutting and machining applications. Overall, the properties of corrosion-resistant stainless tool steel make it a reliable and long-lasting option for demanding industrial and manufacturing settings.

- Q: Can special steel be used in the manufacturing of consumer goods?

- Yes, special steel can be used in the manufacturing of consumer goods. Special steel, with its superior strength, durability, and corrosion resistance properties, can be utilized in various consumer products such as kitchen appliances, cutlery, watches, automotive parts, and electronics. Its use enhances the performance and longevity of these goods, making them more reliable and efficient for consumers.

Send your message to us

51crv4 Hot Rolled Spring Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords