5052 Mill Finish Aluminum Sheet Alloy AA1050 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

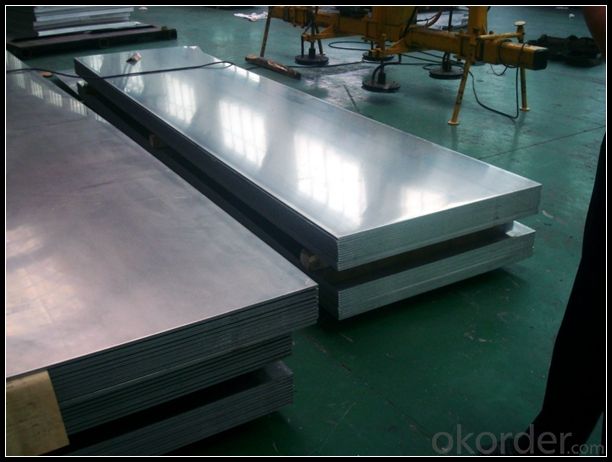

1. Specification of Mill Finish Aluminium Sheet Alloy AA1050 for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet Alloy AA1050 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet Alloy AA1050 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Mill Finish Aluminium Sheet Alloy AA1050 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet Alloy AA1050 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- Duraluminium is cost efficient and best for all purpose.

- Q: If not, where can i buy some aluminum?

- is your minuscule excuse for a dick a dick?

- Q: im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- Aluminum is a good choice if you plan on using it to grind more than just coffee. Plastic tends to soak up flavors due to oils in coffee, herbs and spices. So if you plan on multitasking metal is the way to go.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q: How do aluminum sheets perform in terms of wear resistance?

- Due to their inherent properties and surface characteristics, aluminum sheets generally exhibit good wear resistance. They are lightweight yet durable, boasting a high strength-to-weight ratio, which makes them suitable for various applications that require wear resistance. To further enhance the wear resistance of aluminum sheets, various methods can be employed. Alloying, heat treatment, and surface treatments are among the techniques that can be utilized. By incorporating elements like copper, magnesium, or zinc into aluminum, its hardness and wear resistance can be improved. Heat treatment processes such as precipitation hardening can also bolster the strength and wear resistance of aluminum sheets. Moreover, the wear resistance of aluminum sheets can be significantly enhanced through surface treatments such as anodizing or the application of protective coatings. Anodizing forms a protective oxide layer on the surface of aluminum, providing increased resistance to abrasion, corrosion, and wear. Coatings like powder coatings or paint can also serve as an additional layer of protection against wear and tear. In various industries such as automotive, aerospace, construction, and marine, aluminum sheets find widespread use due to their excellent wear resistance. They are commonly employed in components that undergo sliding, rubbing, or impact, such as panels, body parts, and structural elements. While aluminum sheets may not possess the same level of wear resistance as certain steel alloys or other specialized materials, they offer a favorable balance between strength, weight, and wear resistance. Through appropriate alloying, heat treatment, and surface treatments, aluminum sheets can provide satisfactory wear resistance across a wide range of applications.

- Q: Can the export quality of China's aluminum plate meet the requirement of ASTM B 209? Is this requirement for our country? Master the exhibitions, O (a _ U) O thank you

- This is not quite clear, you Baidu once "work standard net" in "work standard net" check to know!

- Q: How do you ensure the flatness of large aluminum sheets?

- To ensure the flatness of large aluminum sheets, there are several key steps that can be taken: 1. Material selection: Start by choosing high-quality aluminum sheets that are specifically manufactured for flatness. These sheets should have consistent thickness and minimal internal stress to minimize the chances of warping. 2. Proper storage: Store the aluminum sheets in a controlled environment to avoid exposure to extreme temperature fluctuations or humidity. This will help prevent any potential expansion or contraction of the metal, which can lead to warping. 3. Handling and transportation: When moving or transporting the aluminum sheets, ensure that they are supported evenly to prevent any bending or flexing. Use appropriate lifting and handling equipment to avoid excessive strain on the sheets. 4. Machining and processing: During the machining and processing steps, it is crucial to use proper techniques and equipment to maintain flatness. Employ precision machinery that is capable of handling large sheets and has features to minimize distortion or bending during cutting, drilling, or forming processes. 5. Heat treatment: If necessary, heat treatment can be employed to relieve any residual stress in the aluminum sheets. Thermal stress relief techniques, such as annealing, can help reduce internal stress and improve flatness. 6. Quality control: Implement a rigorous quality control process to ensure the flatness of the aluminum sheets. This can include regular inspections using precision measuring instruments, such as straightedges or laser scanners, to detect any deviations from flatness. If any issues are identified, corrective actions can be taken promptly. By following these steps, manufacturers can ensure the flatness of large aluminum sheets, which is crucial for various industries such as aerospace, automotive, construction, and manufacturing.

- Q: what's the difference between zinc sheet and aluminum sheet?

- Only the zinc sheet reacts after adding concentrated nitric acid in drops ,zinc is amphoteric.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Yes, aluminum sheets are commonly used for aircraft manufacturing. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for constructing various components of an aircraft. It is strong enough to withstand the stresses and strains experienced during flight, while also being malleable enough to be formed into various shapes and sizes. Additionally, aluminum sheets can be easily joined together using various welding techniques, allowing for efficient and effective assembly of aircraft structures. Overall, the use of aluminum sheets in aircraft manufacturing helps to ensure a balance between strength, weight, and durability, making it a preferred material in the aerospace industry.

Send your message to us

5052 Mill Finish Aluminum Sheet Alloy AA1050 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords