430 Stainless Steel Plate ss400 hardness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

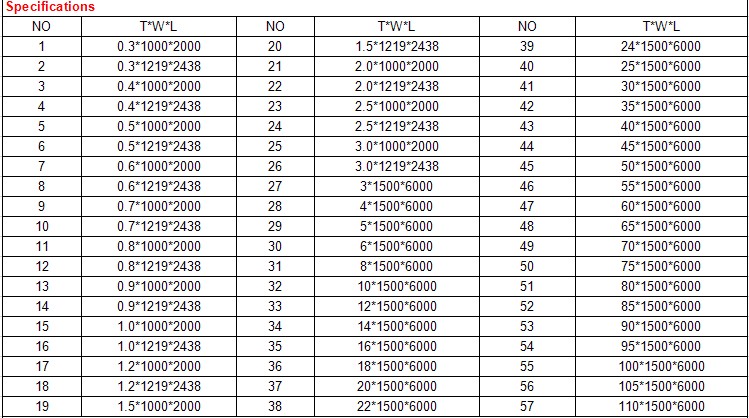

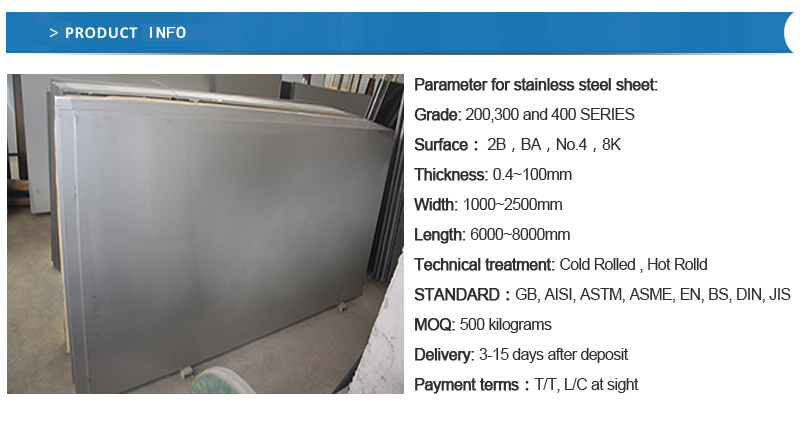

| Product Details |

| Product name | Stainless steel sheet |

| Brand name | RONSCO |

| Standard | ASTM A240, ASTM A480, EN10088, JIS G4305 |

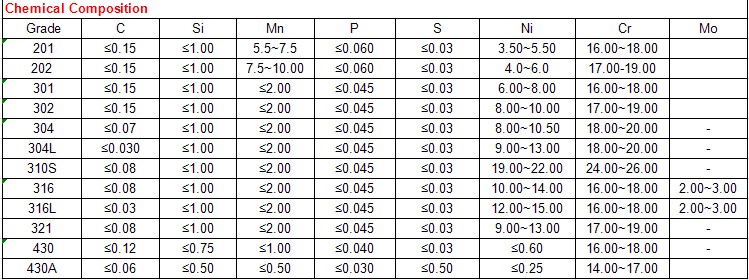

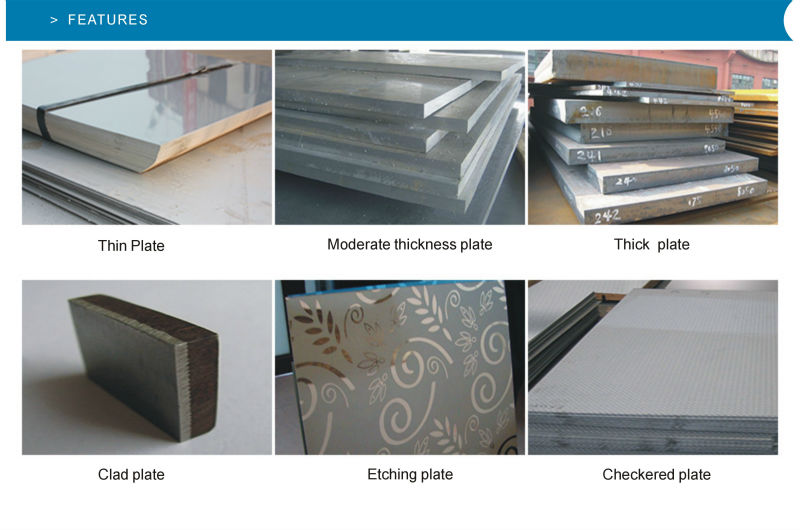

| Material | 304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

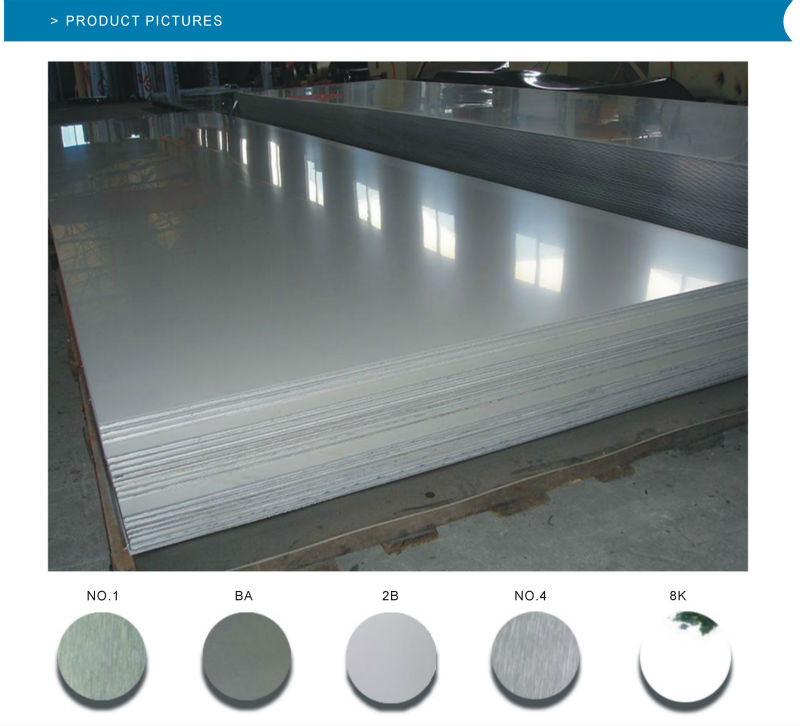

| Surface | NO.1,2B,NO.4,BA,SB,Satin,Brushed,Hairline,Mirror |

| Payment | T/T,L/C at sight |

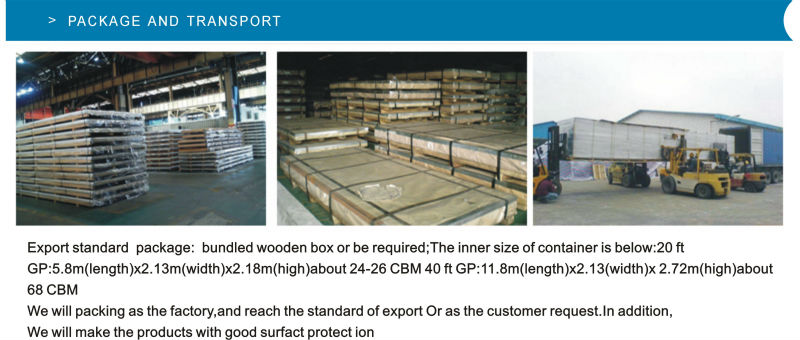

| Packing | In wooden cases,in wooden pallets |

| Shipment | By sea, by air, by express |

Click here to get more information

Packaging & Shipping

Packaging is one of the best service of Ronsco, in order to prevent the damage from transit, our finished products are packaged carefully. All of our stainless steel sheet products will be transported with steel pallets or wooden pallets.

Customers will be guaranteed that the product they received from Ronsco can go directly into the production and out to the customers as finished product.

- Q:What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on several factors, such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel exhibits a relatively high electrical resistance when compared to other metals. This is primarily due to its composition, which includes a significant amount of chromium and other alloying elements that impede the flow of electric current. However, the precise value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Consequently, it is essential to refer to the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q:Can stainless steel sheets be used for fermentation tanks?

- Fermentation tanks can indeed utilize stainless steel sheets. The reason behind this preference lies in stainless steel's durability, resistance to corrosion, and capability to maintain the desired temperature. Its non-reactive nature guarantees the purity and quality of the product by preventing any interaction with the fermenting substances. Furthermore, stainless steel's easy-clean and sanitize properties are vital in ensuring hygienic conditions throughout the fermentation process. On top of all that, stainless steel sheets can be shaped and sized according to specific requirements for fermentation tanks. Consequently, stainless steel sheets are a dependable and popular choice in multiple industries, including brewing, winemaking, and food processing.

- Q:Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers.

- Q:Are stainless steel sheets suitable for elevator wall panels?

- Yes, stainless steel sheets are suitable for elevator wall panels. Stainless steel is a popular material choice for elevator wall panels due to its durability, corrosion resistance, and aesthetic appeal. Elevators are high-traffic areas that require a material that can withstand constant use and potential impact. Stainless steel sheets are robust and can withstand wear and tear. Additionally, stainless steel is highly resistant to corrosion, making it suitable for environments with high humidity or exposure to chemicals. Furthermore, stainless steel has a sleek and modern appearance that adds a touch of elegance to the elevator interior. Overall, stainless steel sheets are a reliable and aesthetically pleasing choice for elevator wall panels.

- Q:Are stainless steel sheets available in different finishes?

- Yes, stainless steel sheets are available in different finishes.

- Q:How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q:What are stainless steel sheets?

- Stainless steel sheets are flat metal plates made from an alloy of iron, chromium, and other elements that prevent corrosion and rusting. They are commonly used in various industries such as construction, automotive, and manufacturing, due to their durability, strength, and resistance to staining and oxidation.

- Q:Can stainless steel sheets be bent?

- Stainless steel sheets have the capability to be bent. This material, known for its versatility, can be molded into different forms and designs, including bends. The capacity to bend stainless steel sheets relies on their thickness and composition. Generally, thinner sheets are more pliable and easier to bend, whereas thicker sheets might necessitate specialized tools and techniques. It is crucial to bear in mind that the bending procedure could potentially weaken the strength and durability of the stainless steel sheet. Therefore, careful thought should be given to the particular application and requirements before embarking on the bending of stainless steel sheets.

- Q:Can stainless steel sheets be used for food storage containers?

- Yes, stainless steel sheets can be used for food storage containers. Stainless steel is a safe and hygienic material for storing food as it is non-reactive, resistant to corrosion, and does not leach any harmful substances into the food. It is commonly used in commercial kitchens and food processing industries due to its durability and ease of cleaning.

- Q:Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

430 Stainless Steel Plate ss400 hardness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords