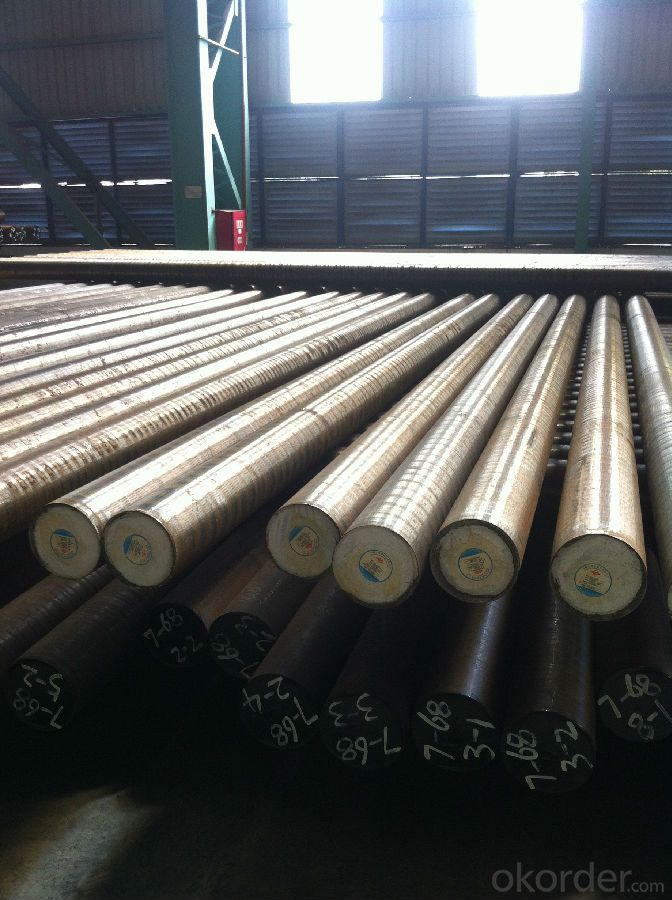

42CrMo Hot Rolled Alloy Round Bar 95-280mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Information

· Place of Origin:China

· Application :Structural Steel Bar

· Dimensions :95mm to 280mm

· Steel Grade :42CrMo

· Technique :Hot Rolled

· Type :Alloy Steel Bar

Product

Annual output of 1.1 million tons of steel including 800 thousand tons of continuous casting round bloom and 200 thousand tons of heavy ingot, and annual output of 750 thousand tons of hot rolled products.

Products, mainly including: railway wheel and tyre steel, bearing steel, spring steel, gear steel, tool and die steel, alloy tube billet, high quality ring steel, high grade cold heading steel, non-quenched and tempered steel, anchor chain steel, roller steel, steel for heavy castings and forgings, alloy structural steel and other series,are widely used in railway, energy, autos, machinery, construction, petroleum, chemical industry, metallurgy, aerospace, marine and other fields.

Chemical composition

C :0.38~0.45%

Si:0.17~0.37%

Mn:0.50~0.80%

S :≤0.035%

P :≤0.035%

Cr:0.90~1.20%

Ni:≤0.030%

Cu:≤0.030%

Mo:0.15~0.25%

Features of this kind of material

1) High fatigue strength and impact resistance after tempering

2) Good low-temperature impact toughness

3) No obvious temper brittleness

Size: Diameter 95mm-280mm

Length: 4m-12m

Delievery condition:

1.Both end of each bar must be cut.

2.Ladle furnaced and vacuum de-gassed

3.Show Heat No. on each bar

4.Surface condition: The surface of the bar shall be free cracks, scar and wrinkles at affect the use of the billets.

5.The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be within the limit stipulated in the contract.

- Q: How is corrosion-resistant tool steel used in the production of molds and dies?

- Corrosion-resistant tool steel is commonly used in the production of molds and dies due to its ability to withstand exposure to corrosive environments. This steel helps to prevent rust and degradation, ensuring that the molds and dies maintain their structural integrity and dimensional accuracy over time. By using corrosion-resistant tool steel, manufacturers can produce high-quality molds and dies that are durable and resistant to wear and tear, ultimately improving the overall efficiency and longevity of the production process.

- Q: What are the different applications of special steel in the construction industry?

- Special steels are highly versatile materials that find numerous applications in the construction industry. One of the primary uses of special steel in construction is in the production of structural components. Special steels, such as high-strength low-alloy (HSLA) steel and weathering steel, are commonly employed to construct buildings, bridges, and other infrastructure projects that require superior strength and durability. In addition to structural applications, special steel is also extensively utilized in the construction of pipelines. This is particularly true for oil and gas pipelines, where special steels with excellent resistance to corrosion and high-pressure conditions are crucial. Stainless steel, for instance, is commonly employed due to its exceptional corrosion resistance properties, making it ideal for harsh environments. Another vital application of special steel in construction is in the production of reinforcing bars, commonly known as rebars. Reinforcing steel bars are used to reinforce concrete structures, such as buildings, bridges, and highways, by providing additional strength to withstand tension forces. Special steel rebars, such as micro-alloyed steel or carbon steel, are specifically designed to enhance the structural integrity and durability of concrete structures. Furthermore, special steel is extensively used in the construction of high-rise buildings and skyscrapers. The exceptional strength, ductility, and fire resistance properties of special steels, such as carbon steel or alloy steel, make them ideal for constructing tall structures that can withstand heavy loads and resist the impact of fire incidents. Special steel also finds application in the construction of equipment and machinery used in the construction industry. For instance, high-speed steel (HSS) is commonly used to manufacture cutting tools, drill bits, and saw blades that are essential for various construction activities. HSS possesses exceptional hardness, wear resistance, and high-temperature strength, making it suitable for heavy-duty cutting and drilling applications. In conclusion, special steel plays a crucial role in the construction industry due to its superior strength, durability, corrosion resistance, and fire resistance properties. It finds applications in structural components, pipelines, reinforcing bars, high-rise buildings, and construction machinery. Special steel ensures the safety, longevity, and reliability of construction projects, making it an essential material in the industry.

- Q: Can special steel be used in the production of gearboxes?

- Yes, special steel can be used in the production of gearboxes. Special steel, such as alloy steel or tool steel, offers higher strength, durability, and wear resistance, making it suitable for use in gearboxes that require heavy-duty performance and efficient power transmission.

- Q: How does special steel perform in extreme cold temperatures?

- Special steel is custom-made to excel under frigid conditions, with alloys that possess a high level of low temperature ductility. This quality enables the steel to maintain its structural integrity even in the harshest cold settings, making it a popular choice in Arctic exploration, oil and gas operations in cold regions, and the aerospace industry. A key distinguishing feature of special steel is its resistance to brittleness when exposed to low temperatures. Unlike regular steel, which becomes brittle and susceptible to cracking in extreme cold, special steel retains its toughness, rendering it suitable for sub-zero conditions. This remarkable attribute is achieved through meticulous selection and control of the alloy's composition, allowing for a superior balance between strength and ductility. Moreover, special steel boasts exceptional resistance to corrosion, a particularly crucial trait in cold environments where exposure to snow, ice, and moisture is prevalent. The alloying elements present in special steel, such as chromium and nickel, generate a protective oxide layer on the surface, successfully preventing corrosion and preserving the steel's structural integrity. Additionally, special steel exhibits remarkable thermal conductivity, enabling efficient heat transfer even in extremely cold temperatures. This thermal property is of paramount importance in applications where effective heat management is essential, such as in the aerospace industry or in equipment operating in cold climates. In summary, special steel is meticulously engineered to excel in extreme cold temperatures. Its low temperature ductility, resistance to brittleness, corrosion resistance, and thermal conductivity establish it as a dependable and enduring material for diverse applications in cold environments.

- Q: Can special steel be used in the production of hydraulic components?

- Yes, special steel can be used in the production of hydraulic components. Special steel possesses superior strength, corrosion resistance, and durability properties, making it suitable for applications in the hydraulic industry. Special steel can withstand high pressure, extreme temperatures, and abrasive environments, ensuring reliable and efficient operation of hydraulic systems.

- Q: How is the toughness of special steel measured?

- The toughness of special steel can be assessed by specific tests and methodologies that evaluate its capacity to absorb energy and withstand fractures. One widely used approach is the Charpy V-Notch (CVN) test, in which a notched specimen is struck by a pendulum hammer, and the energy absorbed during fracture is measured. The results are then expressed as the energy absorbed per unit area, typically in joules per square centimeter (J/cm²) or foot-pounds per square inch (ft-lb/in²). Another commonly employed test is the Izod test, which is similar to the CVN test but involves a different specimen geometry. Furthermore, engineers and manufacturers may also employ other mechanical tests such as tensile strength, impact strength, and fracture toughness measurements to evaluate the toughness of special steel. These tests are invaluable in determining the suitability of special steel for various applications, particularly those requiring exceptional resistance to impact or sudden loading.

- Q: What are some innovative applications of special steel?

- Some innovative applications of special steel include its use in the construction of high-rise buildings, bridges, and other infrastructure projects, where its strength and durability are crucial. Special steel is also utilized in the automotive industry for the manufacturing of lightweight yet strong components, such as car frames and engine parts. Furthermore, it is used in the aerospace sector for aircraft manufacturing, as it offers excellent resistance to extreme conditions and high temperatures. Additionally, special steel is employed in the medical field for the production of surgical instruments and implants due to its biocompatibility and corrosion resistance.

- Q: What are the different methods of improving the impact toughness of special steel?

- There are multiple ways to increase the impact toughness of special steel. Here are a few commonly utilized techniques: 1. Heat Treatment: Heat treatment is a highly effective method that involves subjecting the steel to specific heating and cooling processes. For example, quenching and tempering can significantly enhance the impact toughness of steel. Quenching rapidly cools the heated steel in a liquid medium like oil or water, while tempering involves reheating the quenched steel to a specific temperature and then slowly cooling it. This process refines the steel's microstructure, making it more resistant to fractures and improving its impact toughness. 2. Alloying: Another method is alloying, which entails adding specific elements to the steel composition. Elements like nickel, chromium, and molybdenum can enhance the toughness of steel by modifying its microstructure and improving its resistance to impact. These alloying elements reduce the formation of brittle phases and enhance the steel's ductility. 3. Grain Refinement: The grain size of steel is crucial in determining its impact toughness. By refining the grain size, the steel can exhibit improved toughness. This can be achieved through techniques like controlled rolling or severe plastic deformation. These methods break down large grains and promote the formation of smaller, more uniform grains, resulting in enhanced toughness. 4. Shot Peening: Shot peening is a surface treatment technique that involves bombarding the steel surface with small metallic or ceramic shots. This process induces compressive stress on the surface, reducing the likelihood of crack propagation and improving impact toughness. 5. Welding Techniques: When welding special steel, specific techniques can be employed to enhance its impact toughness. Preheating the steel before welding and controlling welding parameters like heat input and cooling rate help reduce the formation of brittle phases and improve the toughness of the welded joint. It's important to consider various factors like the desired level of toughness, the steel composition, and the intended application when selecting the appropriate method for improving the impact toughness of special steel. A comprehensive understanding of the steel's properties and specific requirements is crucial in determining the most suitable method for enhancing its impact toughness.

- Q: How does special steel contribute to the electrical industry?

- The electrical industry relies heavily on special steel to produce a wide range of components and equipment required for the generation, transmission, and distribution of electricity. Power transformers, for instance, heavily rely on special steel. These transformers are crucial for adjusting voltage levels in the electricity grid, allowing for efficient transmission and distribution of electricity. Special steel, thanks to its exceptional strength, durability, and magnetic properties, is employed to construct the cores of these transformers. The high magnetic permeability of special steel ensures minimal energy loss during the transformation process, resulting in more efficient power transmission. In addition, special steel is extensively used in the manufacturing of electrical conductors, such as wires and cables. These conductors are responsible for transporting electricity from power plants to various end-use applications. Special steel wires boast excellent conductivity and resistance to corrosion, making them ideal for transmitting electricity over long distances with minimal energy loss. Moreover, special steel is employed in the production of electrical connectors and terminals, ensuring secure and reliable connections between different electrical components. The electrical industry also relies on special steel for the fabrication of electrical motors and generators. The exceptional strength and magnetic properties of special steel contribute to the efficient conversion of electrical energy into mechanical energy, ensuring the smooth operation of motors and generators. Furthermore, special steel is used in the manufacturing of electrical switches, circuit breakers, and other protective devices, guaranteeing the safe and reliable functioning of electrical systems. Overall, special steel plays an indispensable role in the electrical industry by enabling the production of essential components and equipment necessary for the generation, transmission, and distribution of electricity. Its unique properties contribute to enhanced energy efficiency, reliability, and safety in electrical systems, cementing its status as an indispensable material in this industry.

- Q: What are the main factors affecting the fatigue strength of special steel?

- Several main factors influence the fatigue strength of special steel: 1. Material composition: The fatigue strength of special steel is determined significantly by its chemical composition. Alloying elements like carbon, chromium, molybdenum, and nickel can improve the material's ability to withstand cyclic loading and enhance its resistance to fatigue. 2. Microstructure: The fatigue strength of special steel is greatly affected by its microstructure, including grain size, crystallographic texture, and the presence of precipitates or phases. Fine-grained structures generally have higher fatigue strength due to reduced stress concentrations and improved resistance to crack initiation and propagation. 3. Surface condition: The fatigue strength of special steel can be significantly impacted by the surface finish and integrity. Surface defects such as scratches, notches, or roughness can act as stress concentrators and initiate fatigue cracks. Proper surface treatments like grinding or shot peening can reduce stress concentrations and introduce compressive residual stresses, improving fatigue resistance. 4. Heat treatment: The fatigue strength of special steel can also be influenced by the heat treatment process used to modify its structure and properties. Appropriate heat treatment techniques like quenching and tempering can optimize the material's microstructure, enhance its hardness, and improve its resistance to fatigue. 5. Loading conditions: The fatigue strength of special steel is greatly influenced by the type and magnitude of cyclic loading applied to it. Factors such as stress amplitude, mean stress, load ratio, and frequency of loading can all impact the material's fatigue life. 6. Environmental conditions: The fatigue strength of special steel can be decreased by the presence of corrosive environments, high temperatures, or other harsh conditions. Environmental factors can accelerate crack initiation and propagation, leading to reduced fatigue life. Selecting corrosion-resistant alloys or applying protective coatings can mitigate the adverse effects of the environment on fatigue strength. By considering and optimizing these factors, manufacturers and engineers can enhance the fatigue strength of special steel, ensuring its reliability and longevity in various applications.

Send your message to us

42CrMo Hot Rolled Alloy Round Bar 95-280mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords