4 Tons Diesel Powered Forklift product CPCD40FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Design types

A truck mounted forklift.

The following is a list, in no particular order, of the more common lift truck types:

Hand pallet truck - no on-board power system of any kind; the operator's muscle power is used to jack-up and move loads.

Walkie low lift truck- powered pallet truck, usually electrically powered

Rider low lift truck - usually electrically powered

Towing tractor - may be internal combustion engine or electrically powered

Walkie stacker - usually electrically powered

Rider stacker - usually electrically powered, e.g., A Ergo

Reach truck - variant on a Rider Stacker forklift, designed for small aisles, usually Electrically Powered, named because the forks can extend to reach the load. There are two variants, moving carriage, which are common in North America, and moving mast which are common in the rest of the world, and generally regarded as safer

Electric Counterbalanced truck- comes in Stand on End Control, Stand on Center Control, and Sit Down Center Control, which is the most numerous

Internal Combustion Engine Powered Counterbalanced Forklift- comes in Stand on End Control, Stand on Center Control, and Sit Down Center Control, which is the most numerous. Engines may be diesel, kerosene, gasoline, natural gas, butane, or propane fueled, and may be either two stroke spark ignition, four stroke spark ignition (common), two stoke compression ignition, and four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems.

Electric forklifts - powered by lead-acid batteries, several types of forklifts are electric: cushion tire forklifts, scissor lifts, order pickers, stackers, reach trucks and pallet jacks. Electric forklifts are primarily used indoors on flat, even surfaces. Electric forklift batteries last 6 consecutive hours or throughout an 8-hour shift with 2-3 breaks. Batteries prevent the emission of harmful fumes and are recommended for facilities in food-processing and healthcare sectors.

Fuel cell forklifts produce no local emissions, can work for a full 8-hour shift on a single tank of hydrogen, can be refueled in 3 minutes and have a lifetime of 8–10 years. Fuel-cell-powered forklifts are often used in refrigerated warehouses as their performance is not degraded by lower temperatures.

Sideloader - comes in Stand on End Control, and Sit Down End Control, which is the most numerous. It may be electrically powered, or have an internal combustion engine. Engines may be diesel, kerosene, gasoline, natural gas, butane, or propane fueled, and may be either two stroke spark ignition, four stroke spark ignition (common), two stoke compression ignition, and four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems. Some sideloaders have hybrid drivetrains.

Telescopic handler - comes in Stand on Center Control, and Sit Down Center Control, which is the most numerous. Usually has an Internal Combustion Engine. Engines are almost always diesel, but sometimes operate on kerosene, and sometimes use propane injection as a power boost. Some old units are two stoke compression ignition, most are four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries like Iran or Russia will typically have no emission control systems. Some Telescopic handlers have Hybrid drivetrains.

Walkie Order Picking truck - usually Electrically Powered

Rider Order Picking truck - commonly called an "Order Picker"; like a small Reach Truck, except the operator rides in a cage welded to the fork carriage, while wearing a specially designed safety harness to prevent falls. A special toothed grab holds the pallet to the forks. The operator hand transfers the load onto the pallet one article at a time. This is an efficient way of picking less than pallet load shipments, and is popular for use in large distribution centers.

Forklift Specification:

Model | CPCD40FR | |

Load capacity kg | 4000kg | |

Load center mm | 500mm | |

Power type | Diesel | |

Max.lifting speeds(with load)mm/s | 300mm/s | |

Max.Driving speeds(with without load) km/h | 18/20km/h | |

Max.Towing speeds | 16.5/11.5kN | |

(with/without load)kN |

| |

Gradeability(with/without load)% | 15/20% | |

H1 Lifting height mm | 3000mm | |

Free lift mm | 80mm | |

Tilting angles(forward-backward) 。 | 6/12 | |

Min. turning radius mm | 2720mm | |

Min. right angle aisle width mm | 2320mm | |

Min. under-clearance mm | 135mm | |

Dimensions | A Overall length(inincluding fork) mm | 4100mm |

B Overall width mm | 1230mm | |

H Overall height(mast lowered) mm | 2100mm | |

H2 Overall height (mast extend) mm | 4270mm | |

H3 Overall height to overhead guard mm | 2110mm | |

A1 Fork overhang mm | 470mm | |

A2 Wheel base mm | 1900mm | |

Tread | B1 Front tread mm | 1060mm |

B2 Rear tread mm | 970mm | |

Tyre | Front tyre | 250-15 |

Rear tyre | 6.50-10 | |

Total weight kg | 4900kg | |

B3 Fork width mm | 150mm | |

H4 Fork thickness mm | 50mm | |

Backrest height mm | 1225 | |

A3 Fork length mm | 1220mm | |

Engine | Engine model | 498 |

Rate power KW | 45KW | |

Rotate Speed At Rate Power rpm | 2500 | |

Max.torque Nm | ≥93 | |

Rotate speed at max torque rpm | 1800-1900rpm | |

Type of power shift | Hydraulic | |

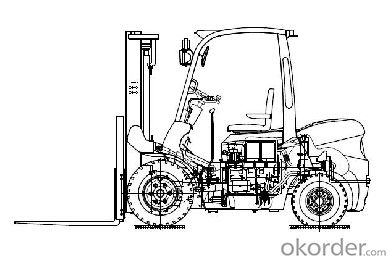

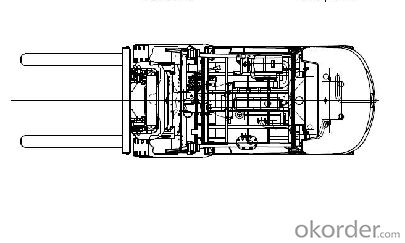

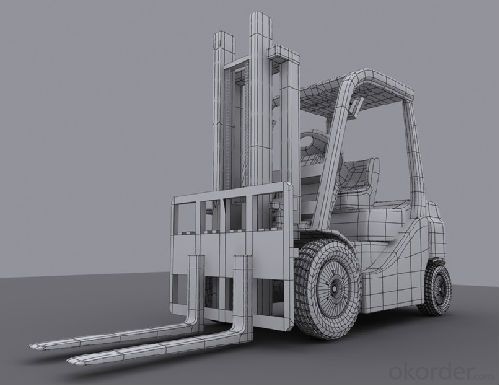

Forklift images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: What are the rules for the forklift

- I don't know what you are talking about, a forklift 2 years certificate, 3 months maintenance! The average speed limit is 5 kilometers.

- Q: What is the difference between the series of internal combustion forklifts

- Lesson together K series belongs to breakdown the chicken cake Weng wine of ten-day palace mo ordinary leather, standard C490 engine, enjoys matching QuanChai 490 engine, by transmission technology agreement, so can't with other engines. The H2000 series, which belongs to the high match model, is the standard of the new chang A490 engine, which can be chosen with the large wood 498, the Japan may bell diesel engine, the nissan petrol engine, the performance is better than the K system. K and H are like the difference between passat and jetta in Shanghai. There is also a higher profile of higher-end product gs, but the price is also high. Lesson together K series belongs to breakdown the chicken cake Weng wine of ten-day palace mo ordinary leather, standard C490 engine, enjoys matching QuanChai 490 engine, by transmission technology agreement, so can't with other engines. The H2000 series, which belongs to the high match model, is the standard of the new chang A490 engine, which can be chosen with the large wood 498, the Japan may bell diesel engine, the nissan petrol engine, the performance is better than the K system. K and H are like the difference between passat and jetta in Shanghai. There is also a higher profile of higher-end product gs, but the price is also high

- Q: Forklift, forklift, loader, which is a special equipment

- Big brother, if I'm not wrong, the forklift is a loader, right? Belong to a special car, forklift and loader you say the modified belongs to the forklift additional fittings, cannot calculate forklift truck, he is also a special car, like a special vehicle is a kind of special equipment, all the technical supervision management

- Q: Skill and use of side forklift?

- Side forklift characteristics: The lateral forklift can carry all sorts of super-long weights, which can be run on narrow channels, which is not possible for the average head forklift truck. The side forklift can carry out the operation of the resetting of various molding goods. We will improve the storage and storage of the goods, and we will standardize the operation of the board, warehouse and yard The necessary machinery. The lateral forklift truck can self-load, self-transport, dump all kinds of large goods, one machine can do more, save the middle process of the job, improve the efficiency of work. The lateral forklift can transfer all kinds of equipment and goods in various places

- Q: Is the stack a forklift truck

- Forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. International standardization organization ISO/TC110 is called an industrial vehicle. Often used for the transportation of large items in storage, usually with a fuel engine or battery. Forklift plays a very important role in the logistics system of the enterprise, which is the main force in the material handling equipment. It is widely used in stations, ports, airports, factories, warehouses and other parts of the national economy. During world war ii, forklifts were developed. China started making forklifts in the early 1950s. Especially with the rapid development of China's economy, the majority of enterprise material handling has been out of the original manual handling, instead of forklift truck is given priority to the mechanization of handling. As a result, demand in China's forklift market has grown at double-digit rates every year for the past few years.

- Q: What about the exhaust fumes of the internal combustion fork in the workshop

- There is a bias towards the diesel fuel and not more than the other is to modify the exhaust system of the engine and the exhaust system is more expensive

- Q: What do you mean by the center spacing of the load on an electric forklift?

- The center of load is the center point of a forklift truck. Generally refers to the center of the length of the goods. General forklift pallet fork length of 1.22 meters, then load center on 610 mm, length is 3 meters of the goods if you, the center of the goods on 1.5 m, with 1.22 m goods fork is certainly not possible

- Q: The forklift truck can't be combined for a license

- No, the loading machine belongs to the engineering machine, the forklift truck belongs to the logistics machinery, different industries.

- Q: What is a forklift worker

- Before the second world war, forklift often and tray and bracket used in combination, but because of the goods in and out of the department or transfer of the goods must be unloaded from the tray, sometimes on the tray back yards, makes many handling system failure. Today, the forklift manufacturing department has designed a variety of special accessories that greatly reduce the use of pallets and add a lot of features to the forklift truck. Forklift truck is the most important characteristics of compact structure, good maneuverability, currently has been widely used in various industrial sectors, as ascension, transporting and stacking the main equipment of various kinds of goods

- Q: I want to learn about the forklift truck. I don't know how well the forklift man works.

- Find a job that is easy to find, and go to the feed factory. At least 3,500 in January, there are five to six thousand, and I did it at the feed factory. You can also go to the electronics factory, but the salary may be more than 3, 000, but it's fun and easy. The answer can help a friend's words, thanks

Send your message to us

4 Tons Diesel Powered Forklift product CPCD40FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords