3.5 Tons Diesel Powered Forklift CPCD35FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Dimensioning devices-fork truck mounted dimensioning systems provide dimensions for the cargo to facilitate truck trailer space utilization and to support warehouse automation systems. The systems normally communicate the dimensions via 802.11 radios. NTEP certified dimensioning devices are available to support commercial activities that bill based on volume.

Sideshifter - is a hydraulic attachment that allows the operator to move the tines (forks) and backrest laterally. This allows easier placement of a load without having to reposition the truck.

Rotator - To aid the handling of skids that may have become excessively tilted and other specialty material handling needs some forklifts are fitted with an attachment that allows the tines to be rotated. This type of attachment may also be used for dumping containers for quick unloading.

Fork positioner - is a hydraulic attachment that moves the tines (forks) together or apart. This removes the need for the operator to manually adjust the tines for different sized loads.

Roll and barrel clamp attachment - A mechanical or hydraulic attachment used to squeeze the item to be moved. It is used for handling barrels, kegs, or paper rolls. This type of attachment may also have a rotate function. The rotate function would help an operator to insert a vertically stored paper into the horizontal intake of a printing press for example.

Pole attachments - In some locations, such as carpet warehouses, a long metal pole is used instead of forks to lift carpet rolls. Similar devices, though much larger, are used to pick up metal coils.

Carton and multipurpose clamp attachments - are hydraulic attachments that allow the operator to open and close around a load, squeezing it to pick it up. Products like cartons, boxes and bales can be moved with this type attachment. With these attachments in use, the forklift truck is sometimes referred to as a clamp truck.

Slip sheet attachment (push - pull) - is a hydraulic attachment that reaches forward, clamps onto a slip sheet and draws the slip sheet onto wide and thin metal forks for transport. The attachment will push the slip sheet and load off the forks for placement.

Drum handler attachment - is a mechanical attachment that slides onto the tines (forks). It usually has a spring-loaded jaw that grips the top lip edge of a drum for transport. Another type grabs around the drum in a manner similar to the roll or barrel attachments.

Man basket - a lift platform that slides onto the tines (forks) and is meant for hoisting workers. The man basket has railings to keep the person from falling and brackets for attaching a safety harness. Also, a strap or chain is used to attach the man basket to the carriage of the forklift.

Telescopic forks - are hydraulic attachments that allow the operator to operate in warehouse design for "double-deep stacking", which means that two pallet shelves are placed behind each other without any aisle between them.

Scales -Fork truck mounted scales enable operators to efficiently weigh the pallets they handle without interrupting their workflow by travelling to a platform scale. Scales are available that provide legal-for-trade weights for operations that involve billing by weight. They are easily retrofitted to the truck by hanging on the carriage in the same manner as forks hang on the truck.

Single-double forks - are forks that in the closed position allow movement of a single pallet or platform but when separated, turn into a set of double forks that allow carryin two pallets side by side. The fork control may have to replace the side-shifter on some lift trucks.

Any attachment on a forklift will reduce its nominal load rating, which is computed with a stock fork carriage and forks. The actual load rating may be significantly lower.

Forklift Specification:

Model | CPCD35FR | |

Load capacity kg | 3500kg | |

Load center mm | 500mm | |

Power type | Diesel | |

Max.lifting speeds(with load)mm/s | 375mm/s | |

Max.Driving speeds(with without load) km/h | 17/19km/h | |

Max.Towing speeds | 16/11kN | |

(with/without load)kN |

| |

Gradeability(with/without load)% | 15/20% | |

H1 Lifting height mm | 3000mm | |

Free lift mm | 80mm | |

Tilting angles(forward-backward) 。 | 6/12 | |

Min. turning radius mm | 2500mm | |

Min. right angle aisle width mm | 2110mm | |

Min. under-clearance mm | 135mm | |

Dimensions | A Overall length(inincluding fork) mm | 3800mm |

B Overall width mm | 1230mm | |

H Overall height(mast lowered) mm | 2100mm | |

H2 Overall height (mast extend) mm | 4270mm | |

H3 Overall height to overhead guard mm | 2110mm | |

A1 Fork overhang mm | 465mm | |

A2 Wheel base mm | 1700mm | |

Tread | B1 Front tread mm | 1000mm |

B2 Rear tread mm | 970mm | |

Tyre | Front tyre | 28×9-15 |

Rear tyre | 6.50-10 | |

Total weight kg | 4580kg | |

B3 Fork width mm | 125mm | |

H4 Fork thickness mm | 50mm | |

Backrest height mm | 1225 | |

A3 Fork length mm | 1220mm | |

Engine | Engine model | 490 |

Rate power KW | 39KW | |

Rotate Speed At Rate Power rpm | 2650rpm | |

Max.torque Nm | 157Nm | |

Rotate speed at max torque rpm | 1980rpm | |

Type of power shift | Hydraulic | |

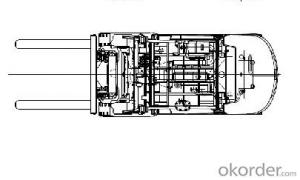

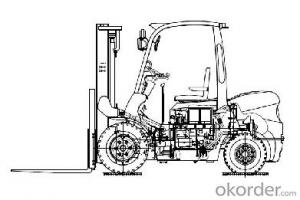

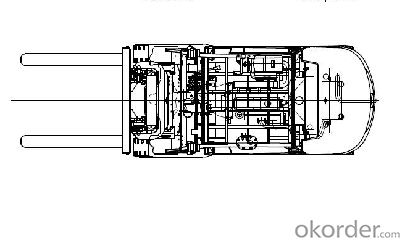

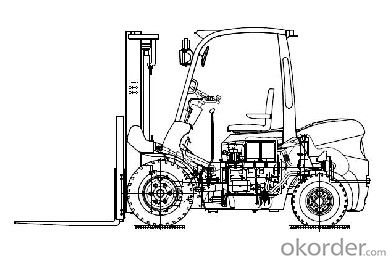

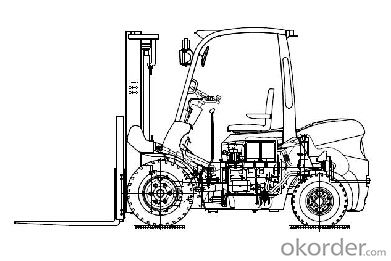

Forklift Images :

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: How many decibels is the sound of a battery forklift? Is it noise? How much does it have to do with neural tinnitus in this environment?

- Different electric car brakes are different, but most of them belong to medium and high frequency sounds, some are harsh, others are noise. Occasionally hearing the effect of a nervous ear is small, but a long or trivial hearing can have a big effect.

- Q: What is the responsibility of the forklift driver for the job?

- If the driver of a forklift truck is employed, the unit shall be liable for compensation. If the driver of a forklift is employed by an individual, the employer shall bear the liability for compensation. The two sides may negotiate a compensation dispute in advance and fail to bring a suit to the court.

- Q: What about the steering wheel of an electric forklift without stepping on the accelerator?

- If the motor is powered by the steering wheel, maybe it's the carbon brush in the motor. Check it out. If I can help you get the best of you

- Q: Electric forklifts can be used for a long time

- You're talking about working hours, which is no problem for eight hours If the working hours are long, you may need two sets of battery rotation

- Q: Please have the annual trial of the forklift licence

- Forklift must be valid for four years now, two years ago You can renew the certificate three months in advance, but you can't pass the validity period. Baidu, guangzhou electrician training post Information!!!!! Guangzhou liu Hoping to help the Lord, Thank you for taking it.

- Q: What is the difference between a forklift mechanical drive and a hydraulic drive?

- The principle of mechanical transmission and hydraulic transmission, fault, maintenance, application cases and other information can try to find something - work sounet data library, the above data can be downloaded for free.

- Q: What are the types of battery forklifts

- And the forward electric forklift truck Carrying capacity of 1.0 ~ 2.5 tons, the door frame can be whole forward or back, back channel width when the operation is 2.7 ~ 3.2 meters, the hoisting height of up to 11 meters, commonly used in warehouse storage, unstuffing, of medium height. Electric pallets carry forklifts Carrying capacity of 1.6 ~ 3.0 tons, homework channel width is generally 2.3 ~ 2.3 meters, goods fork hoisting height is in commonly 210 mm or so, mainly used in the level of the warehouse handling and loading and unloading of goods. There are two modes of walking and driving. 2. Electric pallet stacking forklift bearing capacity is 1.0 ~ 1.6 tons, homework channel width is generally 2.3 ~ 2.3 meters, on the structure more than the electric pallet handling forklift truck door frame, fork cargo hoisting height within 4.8 meters, general is mainly used for stacking and handling of goods in the warehouse.

- Q: Learn the forklift truck, will you be tired in the future?

- The specific job is decided, the forklift truck general is inside the factory son, the person much worry! Hope to adopt!

- Q: How many years can you use a forklift battery

- Generally speaking, it can take two to three years, and it can be recharged about five hundred times. Second, charge attention matters Do not unplug or turn off the power switch when charging, otherwise the plug and the electrical component will be damaged. When the charging authority is closed, the plug is removed. The truck. When configuring the electrolyte, do not pour water into sulfuric acid, lest the temperature of the liquid surface suddenly rise, and the boiling acid droplets will hurl.

- Q: Where to test for a forklift?

- The general exam is to seek the quality board to register, but as you say, ask to provide the data to be more strict If you don't have to do it yourself, it's a lot easier to do it, but I can do it in detail

Send your message to us

3.5 Tons Diesel Powered Forklift CPCD35FR

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords