321 Stainless Steel Sheet with iso9001:2000 certified

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

321 stainless steel sheet with iso9001:2000 certified

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information:

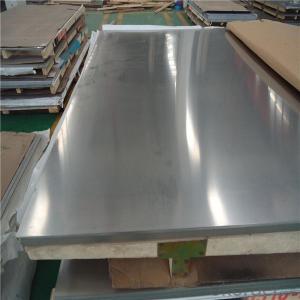

1. Steel grade: 321

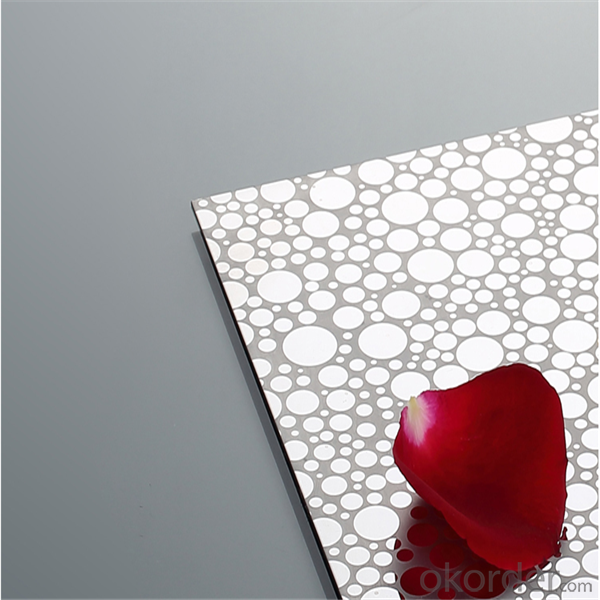

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

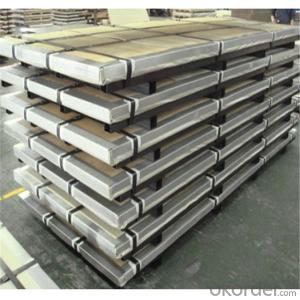

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

Product Name | cheap price 321 stainless steel sheet with iso9001:2000 certified, 321 stainless steel sheet, anti-slip steel plate, stainless steel sheet price 420 |

Steel type | Carbon steel, stainless steel, special alloy steel or as requested |

Process Method | Hot roll, cold roll, cold drawn, ect. |

Other processing method | Cutting, bending, punching, or as customer's request |

Size | Thickness from 0.15mm-300mm, width from 50mm-3500mm, length from 1m-12m or according to customer's special request |

Material grade | Carbon steel :Q195-Q420 Series,SS400-SS540 Series,S235JR-S355JR Series,ST Series,A36-A992 Series,Gr50 Series. Stainless steel: 201,202,304,316,410,420 |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Surface | mild steel plain finish, hot dip galvanized, color coated, ect. |

Size Tolerance | +/- 1%~3% |

Yield Strength | 250~600 MPa |

Tensile Strength | 350~800 MPa |

Packaging | Bundled with strong steel strips or with waterproof packing materials Special packings please discuss with us |

Certificate | API,ISO,SGS,BV,etc |

Capacity | 5000 tons/month, for non-standard customized products please discuss with us |

Delivery terms | FOB / CIF / CFR / DAP or discuss with us for other terms |

Delivery Time | 15-30 days after deposit received or L/C received in our bank |

Application Range | widely used in a variety of architectural and engineering structures,such as 1.) metal constructions such as buildings,bridges,ships; 2.) transmission tower, reaction tower; 3.) lifting transportation machinery; 4.) industrial furnace;boilers 5.) container frame, warehouse goods shelves, etc |

Advantages | 1. We can provide factory price with trading company services. |

2. We control production quality very strictly to keep none compensation. | |

3. We guarantee 24 hours response and 48 hours solution providing service. | |

4. We accept small order quantity before formal cooperation. |

- Q: Several processing techniques of colored stainless steel

- Embossing series: stainless steel embossed plate is through the mechanical equipment in stainless steel plate embossed processing, so that the surface of the board appear concave convex pattern. Also known as stainless steel pattern board.Alternative pattern is made of bamboo pattern, ice bamboo pattern, diamond, square, grain size plate (Zhu Guangwen), oblique stripes, butterfly pattern, chrysanthemum pattern, cube, free lines, oval pattern, stone, panda, antique checkered pattern, according to customers to order or choose the factory pattern press. The embossed plate is bold and bright appearance, surface hardness, higher wear resistance, easy cleaning and maintenance, fight, compression, anti scratch and do not leave fingerprints. Mainly used in architectural decoration, elevator decoration, industrial decoration, facilities decoration, Kitchenware and other stainless steel series.

- Q: Are stainless steel sheets resistant to organic acids?

- Yes, stainless steel sheets are generally resistant to organic acids. Stainless steel is known for its corrosion resistance, and this property extends to its ability to withstand the effects of organic acids. However, the level of resistance can vary depending on the specific composition of the stainless steel and the concentration and type of organic acid being used. In some cases, certain organic acids may cause localized corrosion or pitting on the surface of stainless steel, but overall, stainless steel is considered a suitable material for handling organic acids in various industries such as chemical processing, pharmaceuticals, and food production. It is always recommended to consult with experts or refer to specific stainless steel grades and their compatibility with different organic acids to ensure optimal resistance.

- Q: Can stainless steel sheets be used for decorative staircases?

- Yes, stainless steel sheets can be used for decorative staircases. Stainless steel is a versatile material that offers a modern and sleek appearance, making it an ideal choice for creating decorative staircases. Its durability, resistance to corrosion, and ability to be shaped into various designs make stainless steel sheets a popular option for adding a stylish touch to staircases.

- Q: Can stainless steel sheets be used in the construction industry?

- Yes, stainless steel sheets can be used in the construction industry. They are commonly used for a variety of applications including roofing, cladding, structural supports, and interior finishes. Stainless steel offers excellent corrosion resistance, durability, and aesthetic appeal, making it a popular choice for construction projects.

- Q: Are stainless steel sheets suitable for oil refineries?

- Yes, stainless steel sheets are suitable for oil refineries due to their corrosion resistance, high strength, and ability to withstand high temperatures.

- Q: How do you remove fingerprints from stainless steel sheets?

- If you want to remove fingerprints from stainless steel sheets, there are several effective methods to consider: 1. Begin by using warm soapy water and a soft cloth or sponge. Dampen the cloth or sponge and gently rub the affected area in circular motions. Afterward, rinse the cloth or sponge and wipe away any soap residue. Finally, dry the stainless steel sheet using a clean, lint-free cloth. 2. Another option is to create a vinegar solution by mixing equal parts white vinegar and water in a spray bottle. Directly spray the solution onto the fingerprints and allow it to sit for a few minutes. Then, use a soft cloth to wipe the surface in circular motions, ensuring to follow the grain of the stainless steel. Rinse the cloth and remove any remaining vinegar. Thoroughly dry the sheet. 3. You can also try using a small amount of glass cleaner sprayed onto a soft cloth. Gently rub the fingerprints in circular motions, following the grain of the stainless steel. Repeat if necessary, rinsing the cloth and reapplying cleaner as needed. Finally, dry the surface with a clean cloth. 4. If you prefer, there are various commercial stainless steel cleaners available that effectively eliminate fingerprints. Follow the instructions on the product and apply it to the affected areas. Use a soft cloth to wipe the surface, following the grain of the stainless steel, and buff it to achieve a shine. Always read and adhere to any safety precautions mentioned on the product. Remember to test any method on a small, inconspicuous area first to ensure it does not cause damage or discoloration to the stainless steel sheet. Additionally, avoid using abrasive cleaners or scrub brushes as they can scratch the surface. By properly caring for and regularly cleaning your stainless steel sheets, you can maintain a shiny, fingerprint-free appearance.

- Q: What are the weight calculations for stainless steel sheets?

- The weight calculations for stainless steel sheets depend on their dimensions (length, width, and thickness) and the specific density of stainless steel, which is approximately 7.9 grams per cubic centimeter. To calculate the weight, you multiply the volume of the sheet (length x width x thickness) by the density.

- Q: What are the benefits of using embossed stainless steel sheets?

- Embossed stainless steel sheets offer several benefits. Firstly, they provide a highly durable and long-lasting solution due to the strength and corrosion resistance of stainless steel. Additionally, the embossed pattern adds a unique aesthetic appeal, enhancing the overall look and feel of any space. Furthermore, the embossing helps to hide scratches and fingerprints, making the surface more forgiving and easier to maintain. Lastly, the texture created by embossing adds grip, making it suitable for applications where slip resistance is required, such as flooring or staircases.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets come in various shapes to meet specific requirements and applications. Let's explore some of the most common options: 1. Rectangular sheets: These sheets are widely used and can be easily cut to the desired dimensions. They are available in different standard sizes. 2. Round sheets: Round stainless steel sheets are ideal for decorative purposes or when a seamless or curved surface is desired. They come in various diameters and thicknesses. 3. Square sheets: Similar to rectangular sheets, square stainless steel sheets are versatile and provide a symmetrical and uniform appearance. They can be easily customized to fit specific sizes. 4. Perforated sheets: These sheets have a regular pattern of small holes punched through them. They are commonly used in architectural and industrial applications that require ventilation, filtration, or visibility. 5. Embossed sheets: These sheets feature raised or recessed patterns on their surface, adding texture and visual interest. They find applications in interior design, furniture manufacturing, and automotive industries. 6. Expanded metal sheets: These sheets are created by cutting and stretching a solid stainless steel sheet, resulting in a grid-like pattern with diamond-shaped openings. They are commonly used in security fencing, walkways, and industrial settings. 7. Checker plate sheets: Also known as tread plate or diamond plate, these sheets have a raised diamond pattern on the surface. They are frequently used for slip-resistant flooring, stair treads, and decorative accents. These examples represent just a few of the available stainless steel sheet shapes. The choice of shape depends on the specific requirements, aesthetic preferences, and functional needs of the project.

- Q: How can stainless steel sheets be cleaned and maintained?

- Stainless steel sheets can be cleaned and maintained by using a mild detergent or vinegar solution and a soft cloth to wipe away any dirt or stains. It is important to avoid using abrasive cleaners or scrub brushes that could scratch the surface. Regular cleaning and drying with a soft cloth can help prevent water spots and maintain the shine of the stainless steel. Additionally, avoiding contact with harsh chemicals or acids can help prevent corrosion or damage to the sheets.

Send your message to us

321 Stainless Steel Sheet with iso9001:2000 certified

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords