Stainless Steel Plate 321 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

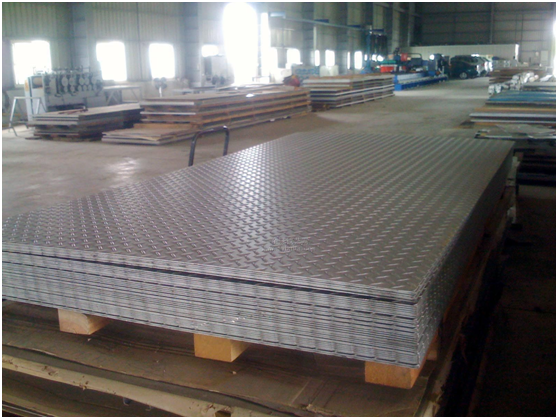

Stainless Steel Plate 321 with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

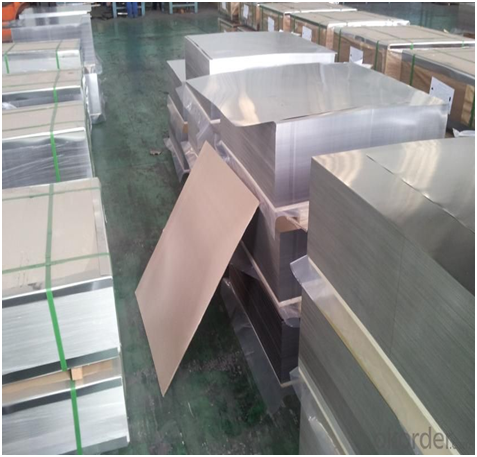

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:Can stainless steel sheets be used for kitchen sinks?

- Yes, stainless steel sheets can be used for kitchen sinks. Stainless steel is a popular material choice for kitchen sinks due to its durability, corrosion resistance, and easy maintenance. Stainless steel sheets are commonly used to fabricate kitchen sinks as they can be molded into various shapes and sizes. The smooth surface of stainless steel also makes it easier to clean and maintain hygiene in the kitchen. Additionally, stainless steel sheets are resistant to heat, stains, and scratches, making them a practical choice for a kitchen sink that is exposed to daily use and potential wear and tear.

- Q:Are stainless steel sheets resistant to UV rays?

- Yes, stainless steel sheets are resistant to UV rays. Stainless steel is known for its durability and corrosion resistance, and this extends to its ability to withstand exposure to UV rays. The chromium content in stainless steel forms a protective oxide layer on the surface, which helps prevent the metal from oxidizing or corroding when exposed to sunlight. This oxide layer acts as a barrier that shields the stainless steel from UV rays, making it highly resistant to the damaging effects of prolonged sun exposure. Therefore, stainless steel sheets are an excellent choice for outdoor applications where UV resistance is a requirement, such as roofing, cladding, and architectural elements.

- Q:Can stainless steel sheets be used for athletic equipment?

- Indeed, athletic equipment can make use of stainless steel sheets. Renowned for their durability, resistance to corrosion, and strength, stainless steel proves to be the perfect material for myriad athletic equipment purposes. Gym equipment, like weightlifting bars, dumbbells, and exercise benches, regularly employs stainless steel in its construction. Moreover, basketball hoops, soccer goalposts, and other outdoor sports equipment rely on stainless steel sheets for their ability to endure harsh weather conditions. Furthermore, stainless steel sheets offer versatility by allowing customization and fabrication into a range of shapes and sizes, catering to diverse athletic equipment requirements.

- Q:What are the costs of stainless steel sheets compared to other materials?

- The costs of stainless steel sheets tend to be higher compared to other materials such as aluminum or carbon steel. This is primarily due to the higher production and fabrication costs associated with stainless steel, as well as its superior corrosion resistance and durability, which make it a popular choice for various applications. However, it's important to consider the long-term benefits and value that stainless steel offers, making it a worthwhile investment in many cases.

- Q:What kind of welding rod is used for 310S stainless steel?

- What kind of welding rod is used for 310S stainless steel?:310S stainless steel should be welded with ER-310 wire or A132 and 137 electrodes.

- Q:How do you cut intricate designs in stainless steel sheets?

- Cutting intricate designs in stainless steel sheets can be a challenging task but can be accomplished through various methods. One common method is using a laser cutting machine. Laser cutting offers precise and clean cuts, allowing for intricate designs to be achieved with ease. The laser beam melts or vaporizes the stainless steel, leaving behind a smooth and precise cut. Another method is using a CNC plasma cutter. This method utilizes a computer-controlled machine that uses a plasma torch to cut through the stainless steel. CNC plasma cutters offer high precision and can handle complex designs. However, the edges may require additional finishing to achieve a smooth and polished look. Waterjet cutting is another option for cutting intricate designs in stainless steel sheets. This method uses a high-pressure jet of water mixed with an abrasive material to cut through the metal. Waterjet cutting is a versatile technique that can handle various thicknesses and designs, producing accurate and detailed results. For smaller projects or intricate designs, a jeweler's saw or a metal nibbler can be used. These handheld tools allow for manual cutting and offer more control over the design. However, they may require more time and effort compared to automated methods. Regardless of the method chosen, it is essential to ensure safety precautions are taken, such as wearing protective gear and following manufacturer's instructions. Additionally, practicing on scrap pieces before working on the final stainless steel sheet can help refine the technique and achieve the desired results.

- Q:How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

- Q:Can stainless steel sheets be used in construction projects?

- Yes, stainless steel sheets can be used in construction projects. Stainless steel is a versatile and durable material that is commonly used in various construction applications. It is known for its corrosion resistance, which makes it suitable for outdoor and high-moisture environments. Stainless steel sheets are often used for roofing, wall cladding, structural components, and decorative features in buildings. They can also be used for interior applications such as countertops, backsplashes, and elevator panels. Additionally, stainless steel sheets are available in various finishes and textures, allowing for customization and aesthetic appeal in construction projects.

- Q:Can stainless steel sheets be used for elevator handrails?

- Yes, stainless steel sheets can be used for elevator handrails. Stainless steel is a popular material for handrails due to its durability, strength, and resistance to corrosion. Elevator handrails are subject to constant use and exposure to various elements, making stainless steel an ideal choice. Additionally, stainless steel can be easily cleaned and maintained, ensuring a hygienic and aesthetically pleasing environment for elevator users.

- Q:What are the benefits of using diamond plate stainless steel sheets?

- Using diamond plate stainless steel sheets offers numerous advantages. Firstly, these sheets are highly durable and resistant to corrosion. Stainless steel is well-known for its strength and ability to withstand harsh environments, making it an ideal option for various uses. The diamond plate pattern further enhances the sheets' durability, providing additional strength and traction. Secondly, diamond plate stainless steel sheets possess a distinctive aesthetic appeal. The diamond pattern not only adds a visually pleasing texture but also helps conceal scratches and dents, resulting in cleaner and more pristine sheets. Consequently, they are a popular choice for architectural and decorative purposes. Moreover, diamond plate stainless steel sheets are effortless to clean and maintain. The smooth stainless steel surface allows for easy cleaning, while the diamond pattern reduces the visibility of dirt and grime. This makes them suitable for environments requiring frequent cleaning, such as commercial kitchens or industrial facilities. Furthermore, these sheets offer exceptional slip resistance. The raised diamond pattern provides traction, minimizing the risk of slips and falls. Consequently, they are particularly valuable in areas prioritizing safety, such as ramps, stairs, or walkways. Overall, diamond plate stainless steel sheets provide durability, corrosion resistance, aesthetic appeal, easy maintenance, and slip resistance. These qualities make them a versatile option for a wide range of applications, including industrial settings and architectural designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Plate 321 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords