316TI Stainless Steel Round Bar price per kg for medical equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Specifications

Name:Stainless Steel Round Bar

1) Standard:ASTM

2) Material: Stainless steel

3) Grade: 201,202,304,304L,316,316L,321...

4) Shape:round bar

5) Surface: Black, Hairline, Bright, Polished

6) Finish: Cold drawn, Hot rolled

7) Diameter: 4-300mm

8) Length: 1000mm-12000mm

9) Payment terms: T/T 30%payment in advance, 70% T/T before shipment or by L/C

10) Packing: Export sea worthy package

11) Delivery time: Within 30 days after receiving 30%T/T of deposit or L/C

Name | Stainless Steel Round Bar for construction |

Standard | ASTM |

Material | Stainless steel |

Grade | 201,202,304,304L,316,316L,321... |

Surface finish | Black, Hairline, Bright, Polished |

Shape | stainless steel Round bar |

Finish | Cold drawn, Hot rolled |

Diameter | 4-300mm |

Length | 1000mm-12000mm |

Packing | Export sea worthy package |

Delivery | Within 30 days after receiving 30%T/T of deposit or L/C |

MOQ | 1MT |

Price terms | FOB, CFR, CIF |

Payment terms | T/T, L/C |

Application | Stainless Steel Round Bar applies to construction,Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistance, electricity industries, etc. |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

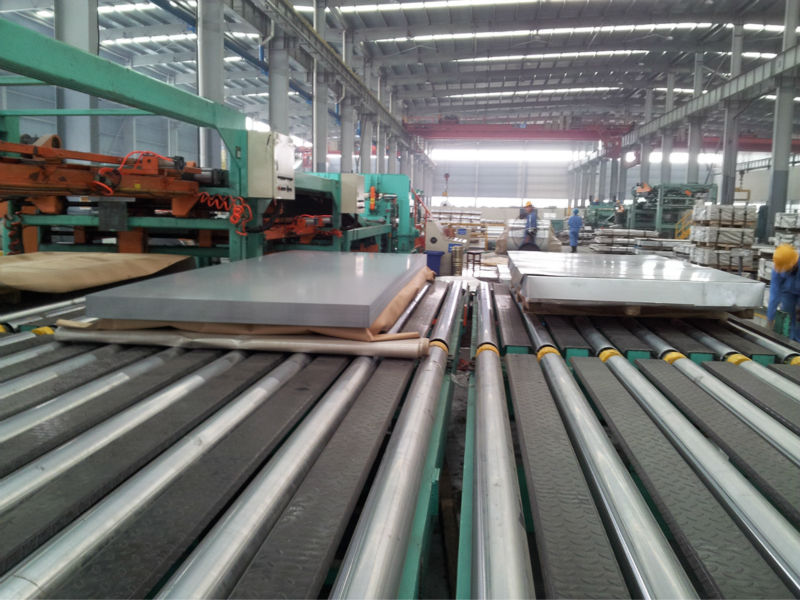

Workshop

Packaging & Shipping

- Q: What are the applications of stainless steel bars in the power generation industry?

- The power generation industry benefits greatly from the remarkable properties of stainless steel bars, which find numerous applications. Let's take a closer look at some key uses: 1. Turbine components: Blades, rotors, and casings in turbines are commonly manufactured using stainless steel bars. These bars possess high strength and exceptional resistance to corrosion, making them well-suited for enduring the harsh operating conditions encountered in power generation turbines. 2. Heat exchangers: Heat exchangers in power plants often rely on stainless steel bars for their construction. These heat exchangers play a critical role in transferring heat between fluids, and stainless steel bars provide the necessary durability and resistance to corrosion, ensuring optimal performance and prolonged lifespan. 3. Boiler tubes: Stainless steel bars frequently contribute to the production of boiler tubes in power generation. These tubes are crucial for converting water into steam, which drives the turbines. Stainless steel bars can withstand high temperatures and pressures while resisting corrosion, guaranteeing the safety and efficiency of the power generation process. 4. Structural supports: Stainless steel bars serve as structural supports in power plants, lending strength and stability to various components and equipment. They are commonly employed in the construction of frames, platforms, and walkways, ensuring the integrity and safety of the power generation infrastructure. 5. Piping systems: The fabrication of piping systems within power plants heavily relies on stainless steel bars. These bars can be shaped and sized accordingly, making them suitable for manufacturing pipes, fittings, and valves. Stainless steel's resistance to corrosion and high-temperature environments ensures the reliability and longevity of the piping system. In summary, stainless steel bars play a crucial role in the power generation industry by providing exceptional strength, corrosion resistance, and durability. Their applications span from turbine components to heat exchangers, boiler tubes, structural supports, and piping systems. The utilization of stainless steel bars guarantees the efficient and reliable operation of power plants, contributing to the generation and supply of electricity.

- Q: Do stainless steel bars require any protective coatings?

- No, stainless steel bars do not require any protective coatings as they are naturally corrosion-resistant due to the presence of chromium.

- Q: Are stainless steel bars suitable for jewelry making?

- Certainly! Stainless steel bars are well-suited for creating jewelry. This material, known for its durability and versatility, is resistant to both corrosion and tarnish. Therefore, it is an excellent option for crafting jewelry that requires strength and longevity, such as bracelets, necklaces, and rings. With stainless steel bars, one can easily shape, cut, and polish them to produce unique and intricate designs. Moreover, stainless steel provides a sleek and contemporary look, making it a popular choice for those who prefer minimalist and modern jewelry styles. Additionally, its affordability compared to precious metals like gold or silver makes it an appealing choice for both jewelry makers and customers. In summary, stainless steel bars offer a combination of durability, versatility, and aesthetic appeal, making them a suitable material for jewelry making.

- Q: Are stainless steel bars resistant to hydrogen-induced cracking?

- Stainless steel bars possess a remarkable ability to resist hydrogen-induced cracking, also recognized as hydrogen embrittlement. The corrosion resistance of stainless steel is widely acknowledged, encompassing its resistance to hydrogen embrittlement. When hydrogen atoms permeate the metal and render it brittle and prone to cracking under stress, hydrogen-induced cracking ensues. Nevertheless, stainless steel exhibits a strong attraction to hydrogen, and the presence of alloying elements in stainless steel aids in minimizing or preventing the diffusion of hydrogen atoms into the metal structure. Consequently, stainless steel bars exhibit exceptional resistance to hydrogen-induced cracking, rendering them suitable for applications where exposure to hydrogen or hydrogen-containing environments is a concern.

- Q: Can stainless steel bars be used in hygienic applications?

- Yes, stainless steel bars can be used in hygienic applications. Stainless steel is known for its corrosion resistance and durability, making it an ideal material for use in environments where cleanliness and hygiene are crucial. It is widely used in industries such as food and beverage, pharmaceutical, and healthcare, where strict sanitary guidelines must be followed. Stainless steel bars are easy to clean and maintain, resistant to bacterial growth, and able to withstand high temperatures and harsh cleaning agents. Additionally, stainless steel is nonporous, preventing the absorption of liquids and contaminants, and is also non-toxic, making it safe for use in contact with food and other sensitive products. Overall, stainless steel bars are a suitable choice for hygienic applications due to their excellent hygiene properties and ability to meet stringent industry standards.

- Q: What is the difference between round and square stainless steel bars?

- The primary distinction between round and square stainless steel bars lies in their shape and structural properties. Round stainless steel bars, as their name implies, have a cylindrical shape with a smooth and even surface. They are frequently utilized in situations where rotational or curved components are necessary, such as in the production of shafts, fasteners, and structural elements. The circular cross-section of round bars also provides increased strength and resistance to bending or twisting forces. On the contrary, square stainless steel bars possess a square-shaped cross-section with four equal sides and sharp corners. This configuration offers benefits in situations that necessitate straight edges or right angles, such as in the construction of frames, brackets, and supports. Square bars are frequently favored for their stability and capacity to evenly distribute weight, making them suitable for load-bearing structures. Regarding structural properties, both round and square stainless steel bars exhibit high tensile strength, corrosion resistance, and durability. However, the shape of the bar can impact certain characteristics. Round bars have a larger surface area, which can enhance heat dissipation and reduce the risk of stress concentrations. Square bars, conversely, provide more contact points and offer superior stability and alignment in various applications. Ultimately, the selection between round and square stainless steel bars is contingent upon the specific requirements of the project, including the desired shape, mechanical strength, and aesthetic appeal.

- Q: What is the thermal expansion coefficient of stainless steel bars?

- The thermal expansion coefficient of stainless steel bars typically ranges from 10 to 17 x 10^-6 per degree Celsius.

- Q: What is the difference between stainless steel bars and stainless steel wire?

- Stainless steel bars and stainless steel wire are both versatile and commonly used materials in various industries. However, there are some key differences between the two. Firstly, stainless steel bars are solid, cylindrical shapes of stainless steel, typically available in various lengths and diameters. They are often used in construction, manufacturing, and structural applications where strength and durability are required. Stainless steel bars are commonly used as supports, braces, and reinforcements due to their solid structure. On the other hand, stainless steel wire is a thin, flexible strand of stainless steel that can be easily bent and manipulated. It is commonly used in industries such as jewelry, mesh manufacturing, and electrical applications. Stainless steel wire is often used for its aesthetic appeal and ability to be woven or twisted into different shapes. It is also used in electrical applications due to its high conductivity and resistance to corrosion. Another difference between stainless steel bars and stainless steel wire is their manufacturing process. Stainless steel bars are typically produced by melting and casting stainless steel into solid forms, which are then machined or hot rolled to achieve the desired shape and dimensions. Stainless steel wire, on the other hand, is produced by drawing or extruding stainless steel through a series of dies to reduce its diameter and increase its length. In terms of strength and load-bearing capabilities, stainless steel bars are generally stronger and able to support heavier loads compared to stainless steel wire. This is because the solid structure of bars provides more stability and resistance to bending or deformation. Stainless steel wire, although not as strong as bars, offers flexibility and versatility, making it suitable for applications where malleability is required. In summary, the main difference between stainless steel bars and stainless steel wire lies in their shape, manufacturing process, and strength. Stainless steel bars are solid, cylindrical structures used for structural applications, while stainless steel wire is a thin, flexible strand used for various purposes such as jewelry-making and electrical applications. Understanding these differences is crucial in selecting the most appropriate material for specific projects or applications.

- Q: Can stainless steel bars be used in medical applications?

- Yes, stainless steel bars can be used in medical applications. Stainless steel is a commonly used material in the medical industry due to its excellent properties such as corrosion resistance, high strength, and durability. These bars can be utilized in various medical applications including surgical instruments, medical implants, and equipment used in medical laboratories. Stainless steel bars are particularly favored in these applications as they can withstand sterilization processes without corroding or degrading, ensuring a high level of hygiene and safety for patients. Furthermore, stainless steel is biocompatible, meaning it does not cause any adverse reactions when it comes into contact with the human body. Overall, stainless steel bars are a reliable and versatile material choice for medical applications.

- Q: Can stainless steel bars be used for construction purposes?

- Yes, stainless steel bars can be used for construction purposes. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various construction applications. Stainless steel bars are commonly used in the construction of buildings, bridges, and infrastructure projects due to their strength and resistance to rust and stains. They are also known for their aesthetic appeal, making them a popular choice for architectural purposes. Additionally, stainless steel bars offer excellent structural stability, making them ideal for applications that require load-bearing capabilities. Overall, stainless steel bars are a reliable and versatile material for construction purposes.

Send your message to us

316TI Stainless Steel Round Bar price per kg for medical equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords