304 Stainless Steel Plate in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4.5

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM International Corporation

CNBM International Corporation

Stainless steel

CNBM began to domestic trade since 70S,now we also sell stainless steel aborad.

We are the agent of TISCO,BAOSTEEL,LISCO,JISCO,ZPSS.

Our main products are stainless steel inox sheet/plate,coil/roll,strip,bar,angle,pipe and tube.

Grade-- 201,202,304,304L,316,316L,310S,309S,301,321,904L,410,420,430,409.

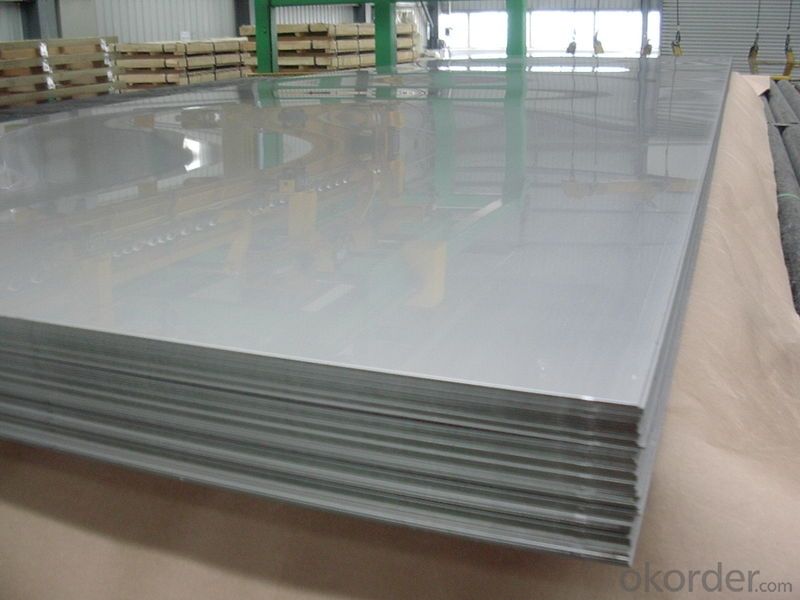

Surface--2B,BA,No.4/HL/Hairline/brushed/satin,8K/No.8/mirror,SB,gold,etch,No.1,polish.

Thickness--0.2-6mm for cold rolled; 3-150mm for hot rolled.

Width:10mm-2000mm for coil.

Standard size --1000×2000mm,1219×2438mm=4ft×8ft=1220×2440mm,

1250×2500mm,1500×3000/6000mm,1524×6096mm.For sheets/plates.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

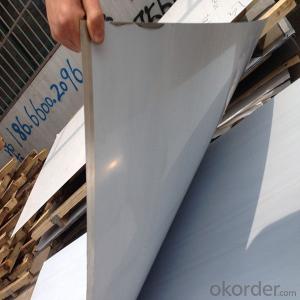

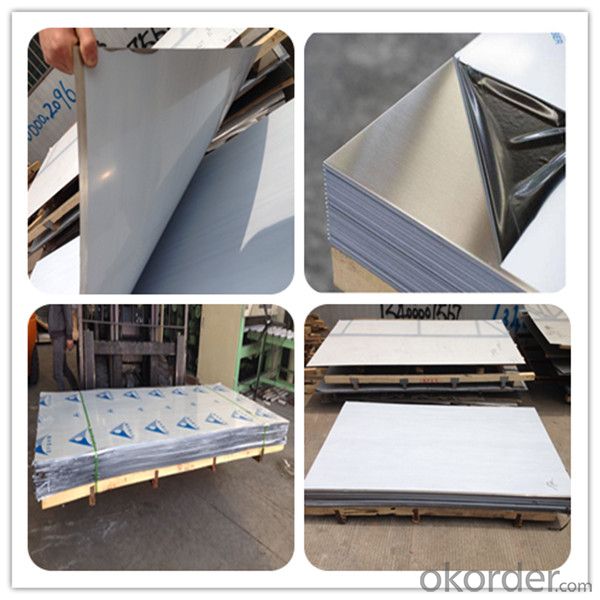

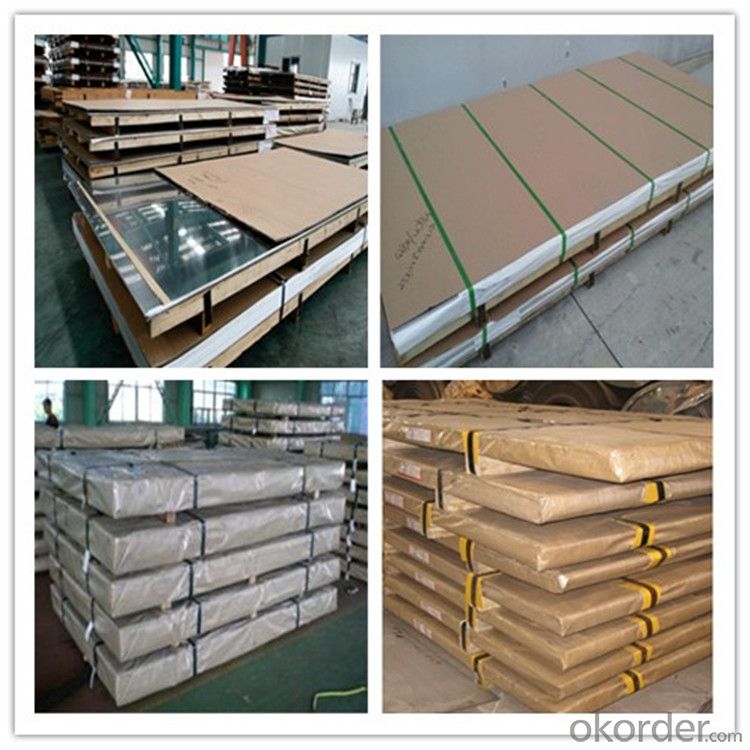

Package--wooden pallets with fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

Product Description

Description of 304 1mm thick stainless steel sheet prices

1 | Product Name | 304 1mm thick stainless steel sheet prices |

2 | Material | ASTM 301, ASTM304,ASTM304L, ASTM 316, ASTM316Ti,ASTM309S, ASTM310S, ASTM321, ASTM347H,ASTM A317,ASTMA317L, ASTM409,ASTM409L,ASTM410,ASTM420,ASTM430 ASTM 201,ASTM202, |

3 | Technique | Cold Rolled Stainless Steel plate Cold Drawn Stainless Steel plate Hot Rolled Stainless Steel plate |

4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

5 | Thickness | 0.2-6.0mm for cold rolled 3.0-300mm for hot rolled |

Width | 600-3000mm | |

Length | Any, as your requirement | |

6 | Surface Treatment | No.1, NO.4 ,2B, BA, Hair Line,8K,Brush,Embossed and Mirror Finish or as your demand |

7 | Packing | Standard export packing-For stainless steel sheet 1.surface polish 2. bundle package 3. wooden case , wooden pallet package 4:container or bulk 5. special according to customer request |

8 | Delivery | Normally according to the order quantity or upon negotiation |

9 | Price Item | FOB,CFR,CIF Or as negotiated |

10

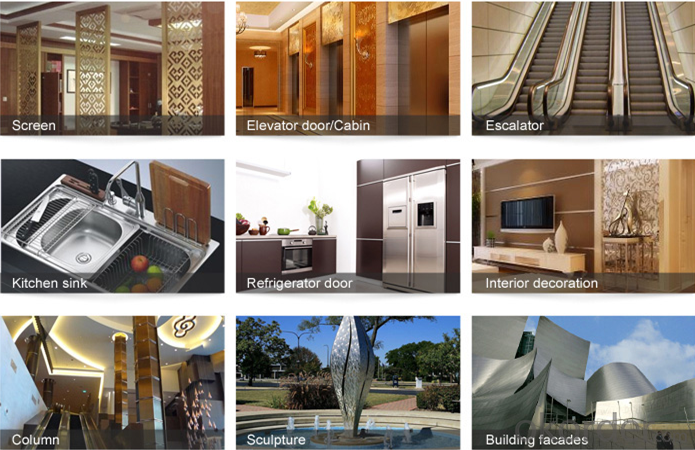

| Application | Stainless Steel plate are widely used in below fields: 1: Construction feild,shipping building industry 2: Petroleum and Chemical Industries 3: Food and Machenical Industries 4: Boiler Heat Exchange 5: Machinery and Hardware Industries |

Mechanical property of 304 1mm thick stainless steel sheet prices

| Tensile Strength | σb (MPa)≥520 |

| Offset Yield Strength | σ0.2 (MPa)≥205 |

| Elongation | δ5 (%)≥40 |

| Hardness | ≤187HB;≤90HRB;≤200HV |

| Density(20℃,g/cm3) | 7.98 |

Chemical composition of 304 1mm thick stainless steel sheet prices

| 316 | C | Si | Mn | P | S | Ni | Cr | Mo |

| % | ≤0.08 | ≤1 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.00-3.00 |

Maintenance of 304 1mm thick stainless steel sheet prices

Regular cleaning and maintenance

Pay attention to prevent the occurrence of the phenomenon of surface scratches

Use soap, weak detergent or warm water to remove surface dust, dirt

In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

Use neutral detergent or ammonia solution in addition to surface oil

With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packaging & Shipping

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

After-sale service:

CNBM provides the services and support you need for every step of our cooperation.

We’re the business partners you can trust; you can relax and get on with doing business.

For any problem, please kindly contact us at any your convenient time,

we’ll reply you in our first priority within 24 hours

Application

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

- Q: How do stainless steel sheets differ from other types of metal sheets?

- Stainless steel sheets differ from other types of metal sheets primarily due to their unique composition, which includes a high percentage of chromium. This gives stainless steel sheets superior resistance to corrosion, staining, and rusting, making them highly durable and ideal for various applications in industries such as construction, automotive, and kitchenware. Additionally, stainless steel sheets are known for their aesthetic appeal, as they have a smooth, reflective surface finish.

- Q: What are the different finishes available for stainless steel sheets?

- Some common finishes available for stainless steel sheets include brushed, mirror, satin, and textured finishes.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are highly resistant to abrasion.

- Q: Can stainless steel sheets be used for elevator flooring?

- Yes, stainless steel sheets can be used for elevator flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevator floors. Additionally, it provides a sleek and modern appearance, making it a popular choice for elevator interiors.

- Q: Are stainless steel sheets resistant to pitting corrosion?

- Yes, stainless steel sheets are resistant to pitting corrosion. Pitting corrosion is a localized form of corrosion that occurs in specific areas, resulting in small pits or holes on the metal surface. Stainless steel sheets are made with a high percentage of chromium, which forms a passive oxide layer on the surface, providing excellent resistance to corrosion. This oxide layer acts as a barrier, protecting the metal from pitting corrosion. Additionally, stainless steel contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to pitting corrosion. Therefore, stainless steel sheets are highly resistant to pitting corrosion and are commonly used in applications where corrosion resistance is crucial, such as in the construction, automotive, and food processing industries.

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding to some extent. While stainless steel is not inherently magnetic, it does have some magnetic properties. Stainless steel alloys contain iron, a magnetic material, which allows them to exhibit weak magnetic characteristics. However, the magnetic shielding effectiveness of stainless steel sheets is limited compared to other materials specifically designed for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more effectively than stainless steel. Nonetheless, stainless steel sheets can still provide some level of magnetic shielding, especially in lower intensity magnetic fields. They can help reduce the transmission of magnetic fields from one area to another, which might be useful in certain applications. However, for high-intensity or sensitive magnetic shielding requirements, it is recommended to use specialized magnetic shielding materials for optimum effectiveness.

- Q: Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a highly corrosive substance, but stainless steel is known for its excellent corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on the surface of the metal, preventing it from reacting with caustic soda. However, it is important to note that the exact resistance of stainless steel to caustic soda may vary depending on the grade or type of stainless steel. Therefore, it is always recommended to consult the specific material specifications or consult with a qualified professional to ensure the appropriate choice of stainless steel for specific applications involving caustic soda.

- Q: Are stainless steel sheets suitable for high-temperature applications?

- Yes, stainless steel sheets are suitable for high-temperature applications. Stainless steel is known for its excellent heat resistance properties, making it an ideal material for use in high-temperature environments. It can withstand extreme heat without losing its strength or structural integrity, making it highly durable and reliable. Stainless steel sheets are often used in industries such as aerospace, automotive, and manufacturing, where high temperatures are common. Additionally, stainless steel sheets have low thermal expansion, which means they can maintain their shape and dimensions even when exposed to fluctuating temperatures. This makes stainless steel sheets a preferred choice for applications where dimensional stability is crucial. Overall, stainless steel sheets are a suitable option for high-temperature applications due to their exceptional heat resistance, durability, and dimensional stability.

- Q: Can stainless steel sheets be used for chemical reactors?

- Yes, stainless steel sheets can be used for chemical reactors. Stainless steel is a popular choice for chemical reactors due to its excellent corrosion resistance properties. It is highly resistant to chemical reactions with various substances, making it suitable for handling corrosive chemicals or environments. Stainless steel sheets are also known for their durability, high strength, and ability to withstand high temperatures, making them suitable for use in chemical reactors that may operate under extreme conditions. Additionally, stainless steel is easy to clean and maintain, which is crucial for ensuring the purity and integrity of the reaction process. Overall, stainless steel sheets are widely used in the construction of chemical reactors and are considered a reliable and effective material choice for this application.

- Q: How do you determine the hardness of stainless steel sheets?

- There are multiple methods available to determine the hardness of stainless steel sheets. The Rockwell hardness test is a commonly used method that involves measuring the depth of indentation on the material's surface. This is done by applying a specific load using a diamond cone or steel ball and measuring the resulting depth of penetration. The Rockwell hardness value is then determined based on this depth. Another method is the Vickers hardness test, which involves using a diamond indenter to create a square-shaped indentation. The size of this indentation is measured and converted into a hardness value. This method is often preferred for thin materials like stainless steel sheets. The Brinell hardness test is an alternative technique where a known load is applied to the material using a hardened steel ball. The resulting indentation's diameter is then measured, and the hardness value is calculated based on both the applied load and the diameter of the indentation. Apart from these mechanical tests, non-destructive methods such as ultrasonic hardness testing and magnetic hardness testing can also be employed. Ultrasonic testing determines the speed of sound through the material, which is then correlated to its hardness. Magnetic hardness testing, on the other hand, measures the magnetic properties of the material, which are affected by its hardness. Overall, the hardness of stainless steel sheets can be determined using various methods depending on the specific requirements and characteristics of the material.

Send your message to us

304 Stainless Steel Plate in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4.5

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords