2015 Green Choice Outdoor WPC/ wood plastic composite (wpc decking)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

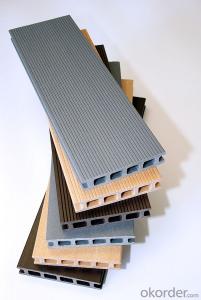

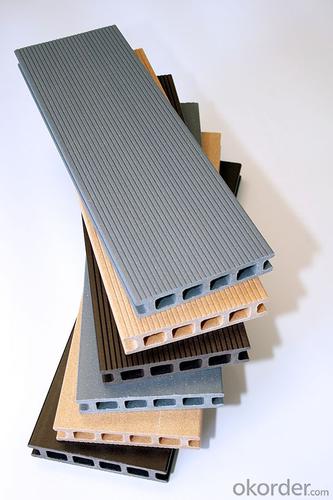

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: What about oak wood flooring?

- Very nice Life of the solid wood flooring is good, consumers want to choose the floor, then there are still a lot of good, I bought before the time to consider is a radius, a new brand Xin Xin, also went to the store looked, Is it true? There are other like the elephant elephant tree, life home, Jinqiao, ridge attack hoarding plateau pan chopped reed raft two Fuer Ma Fulin, radius, peace of mind and so on these, the price is more reasonable. In the famous network 10-china that there are ten top parquet brand ranking, there is time to go to that understanding to see. To buy the product, then you can go to the shopping network gou55 look at the query, the above recommended some shopping sites are also relatively large, the credibility of all aspects are also more secure, buy or you can rest assured it

- Q: Buy the composite floor, relatively cheap, when the sweep is dry with a wet mop dragged, but after the towing or Gong Gong drink drink 鼙 estimated Russia and Taiwan have a watermark with a dry mop can not all drag the watermark and other watermark dry To show a little bit of speculation that is not clean I was not used to clean the water there is no such situation with friends to support more ah

- Here to introduce a clean light-colored composite wood flooring tips: with a rag dipped in Taomi Shui directly on the floor to wipe, or Taomi water evenly sprayed on the wooden floor (not too much), 5 minutes with a dry cloth to wipe, The floor will clean up a lot. Cleaning of special stains: oil stains, paint, ink can be used to wipe the special stains; blood, fruit juice, red wine, beer and other residual stains with a wet cloth or wiped with an appropriate amount of floor cleaning agent wipe; wax and chewing gum, Put on the above for a while, so that the frozen contraction, and then gently blowing, and then wipe with a damp cloth or wiped with an appropriate amount of floor cleaning agent wipe. Can not be used strong acid-base liquid cleaning wood flooring can be specific in the "floor 998 site", above a topic is "on the four types of floor maintenance" are introduced these

- Q: What are the characteristics of solid wood flooring? How is the price?

- Solid wood is relatively more environmentally friendly, foot feel good, but the price is relatively high, take care of relatively more trouble! Solid wood composite flooring stability, suitable for geothermal environment, foot feeling is also good, affordable, but the environmental protection is not solid wood! Strengthen the floor color selection is relatively large, affordable, but the foot is relatively poor! At present, we are divided into solid wood flooring, solid wood flooring, laminate flooring, solid wood flooring, good quality, high price, low floor quality, low price, want to, the price of solid wood flooring Is the highest.

- Q: I am all inclusive to the decoration company. Decoration company recommended to strengthen the floor under the floor put mat, their reason is the guest restaurant and corridor paste tiles, if the bedroom keep the pad is not the same height. But my friend suggested that I strengthen the composite floor under the release of moisture-proof pad, helium Fu Fu Huang Bing Hao Feng kettle pad to keep a long time will be uneven. In the end which kind of better please enlighten God. More

- Of course, is put mattress, helium Fu Huang Bing Hao Feng kettle pad mat with a few years will be uneven, the floor is mainly moisture, put enough mats, decoration companies let you put mats, because they are The ground is not done, there is no good leveling, the height is not the same, you can choose the thickness of the appropriate floor, do not be decorated company flicker.

- Q: What brand is doing well

- Oh, oh, I use composite flooring. Cheap, variety and more

- Q: Last year, one of my friends told me that his home shop is a composite floor, from the static electricity is very powerful, so I do not want to move over the use of the Department of Bodery Bugu Sambo to buy composite floor, and that friend can tell me what happened? Solid wood will not have this problem? [Em00] more

- Only to the floor to anti-static is no effect, I stay in the engine room all day, the floor is to move over the use of barking Dumiao Sen anti-static, if not wearing anti-static shoes and anti-static clothing, dry in the winter Time, wear chemical fiber clothing more, still you did not discuss the electricity, because the room inside the humidifier is broken, the air is too dry.

- Q: How to install the composite flooring is installed? Is the installation of good-looking? Question added: but how is the pin line fixed in the corner?

- Foot line has a fixed lock and yin and yang corner, head; lock in accordance with the location of the foot card slot fixed on the wall, buckle on the foot line, the corner inserted in the corresponding yin, yang horns Hold the head with a straight head.

- Q: New house ready to renovate, bedroom inside want to use composite floor, but I heard that the composite floor radiation, is true or false ah? The The More

- No radiation! Korean and Japanese heating is very developed, the vast majority of residents shop is solid wood flooring. I began to learn nothing about the floor, and later through the study, found the solid wood flooring is the best choice for the following reasons: We all know solid wood flooring (solid wood flooring) in addition to the advantages of solid wood flooring Such as: not easy to deformation anti-Alice, good maintenance, not Jiaoqi, etc.: ① solid wood flooring substrate is more than Liu amine, breathable, comfortable better; ② with the amount of plastic The use of ceramic lacquer, wear resistance are better, but also the use of ceramic paint, But not as strengthen the composite; ⑤ not Jiaoqi, good care. It has a good moisture resistance, because its substrate is the use of criss-cross the willow wood pressed from the wood to eliminate the internal stress. The same solid wood flooring brand a lot, but they have a small production line brand, but also the use of OEM (OEM). Note: the purchase of the floor is not harder the better, because the harder texture, the foot feel worse, and lost the wood itself, sound absorption, moisture and other advantages. Some businesses often use some metal objects to cut the floor to the floor from damage as well, this is just a business promotion gimmick. We know the most obvious truth: the wood must be afraid of iron (the two of the molecular structure is not the same), on the contrary not afraid of the floor of the iron is not necessarily pure wood products. I hope you will not be misled by the advertising of the business. To know the statistics on the floor in terms of complaints, 100 complaints, because the wear problem even one is not, very simple reason ... ... who will be wearing their own high heels will be free to step on it? Or use metal hard objects to knock on their own floor it? The So the real problem is that the floor is cracking, deformation and so on.

- Q: Solid wood flooring multi-layer solid wood composite floor to strengthen the difference between the composite wood floor What is the difference between the few? Thank you!

- Solid wood do not have to worry about formaldehyde problems, but have to worry about deformation, multi-layer solid wood composite is not easy to deformation, the surface texture of the natural, on the rupture of the cake after the Tamagawa grassland formaldehyde requirements, not wearable. Strengthen the composite wear-resistant, affordable, but more formaldehyde problems, the water floor will be completely deformed, relatively speaking, will choose multi-layer solid wood composite, and now the market also has a multi-layer wear-resistant antique floor, floor texture, Of the wear-resistant, only less texture, but the environmental protection, the economy is also moderate, worth choosing!

- Q: What is the price of geothermal reinforced laminate flooring?

- 80-200 yuan between. It is recommended about 100 or so, no matter what brand you use the floor, remember to first ask whether there is no geothermal. And then look at the back of the board, the back raft hides to destroy the disgusting belly rub the color of the sand is the international common orange. I suggest you to look at: the elephant, nature, the couplet.

Send your message to us

2015 Green Choice Outdoor WPC/ wood plastic composite (wpc decking)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords