201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats

Product Description

Specifications:

Grade: 200series; 300series; 400series

Thickness: 0.3mm-100mm

Width: 1000-1500mm

Length: 1000-6000mm

Main properties:

Basic corrosion resistance

Resistance against intergranular corrosion

Heat resistant alloy (medium temperature)

High ductility

Detailed Parameters:

Product Name | 201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats |

| Item Type | 201 Stainless steel |

| Grade | 201, 202, 301, 302, 304, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex, etc |

| Standard | ASTM, AISI, DIN, EN, GB, JIS, ISO |

| Thickness | 0.3mm-100mm |

| Width | 1000-1500mm |

| Length | 1000-6000mm |

| Surface | 2B,NO.1,NO.4,HL,BA,8K |

| Edge | Slit/ /Mill Edge |

| Hardness | Full hardness to DDQ |

| Application | Utensils, kitchenware, food package,industry, construction,decoration etc. |

| Package | Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container or as per customer's requirements. |

| Payment term | T/T 30% deposit before production,70% balance before shipment. |

| Delivery Time | 2-5 days for sample order,within 10 days for formal order. |

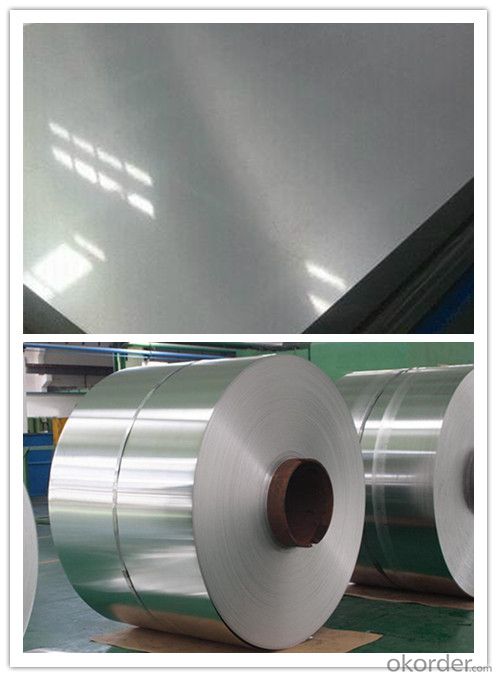

Product Display:

Chemical Composition:

| Grade | C(Max) | Mn (Max) | Si (Max) | P (Max) | S (Max) | Cr | Ni | Mo | Cu/others |

| 201 | 0.15

| 5.5-7.5 | 1 | 0.06 | 0.03 | 16.0-18.0 | 0.8-1.0 | ||

| 202 | 0.15 | 7.5- 10.0 | 1 | 0.06 | 0.03 | 17.0-19.0 | 4.0-6.0 | 1.4-1.5 | |

| 304 | 0.07 | 2 | 0.75 | 0.045 | 0.03 | 17.5-19.5 | 8.0-10.5 | - | |

| 304L | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 17.5-19.5 | 8.0-12.0 | - | |

| 309S | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 22.0-24.0 | 12.0-15.0 | - | |

| 310S | 0.08 | 2 | 1.5 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | ||

| 316 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00- 3.00 | |

| 316L | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00- 3.00 | |

| 321 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | Ti:5(C+N)min | |

| 410 | 0.08-0.15 | 1 | 1 | 0.045 | 0.03 | 11.5-13.5 | 0.75 | 0.70max | |

| 430 | 0.05 | 0.5- 1.0 | 0.6 | 0.045 | 0.03 | 11.5-14.0 | 3.5-5.5 | 0.50- 1.00 |

Surface Treatment:

| Surface | Image Display | Features |

| 2B |  | The surface brightness and flatness of 2B is better than 2D. Then through a specialsurface treatment to improve its mechanical properties, it could nearly satisfy comprehensive uses. |

| No.1 |  | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 |  | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL |  | Polished with abrasive belt of grit #150 #320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA |  | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |  | The product have excellent brightness and prefer reflexivity can be the mirror. |

Packaging & Shipping

1.Package: Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container or as per customer's requirements.

2.Shipping: If we have stocks, the delivery time is less than 5 weekdays,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.Sample or bulk goods we would choose ship by air or by sea after talking with you.

Company Information

Certificate:

FAQ:

1.Q:Are you manufacture or trading company?

A:We are manufacture in Wuxi,Jiangsu Province,China(mainland).

2.Q:Who are your suppliers?

A:We have been working directly with TISCO,LISCO,ZPSS,BAOSTEEL for years.

3.Q:What are the advantages of your products?

A:We specialized in 200,300,400 series cold rolled stainless steel plates.Service for OEM/ODM,any others such as stainless steel strips and strips in coil also supplied on your request.

4.Q:How can I get samples?

A:Our samples are free,but we hope u can pay for the freight fee.2 ways for your choice.

1)U can provide us with an express account no. and contact information for shipping if u have.

2)If u do not have the express account,deposit the freight fee in advance.We will arrange the samples for you as soon as we get the deposit.

5.Q:How much for sending the samples?

A:The freight fee depends on the weight,package size,and the destination to load goods.We would choose the best way to forward.

- Q: Can stainless steel sheets be used for electrical conductivity?

- Typically, stainless steel sheets are not employed for electrical conductivity. Stainless steel is renowned for its exceptional resistance to corrosion and durability, rendering it apt for a diverse range of applications like kitchen appliances, construction materials, and industrial equipment. Nevertheless, stainless steel falls short in terms of conductivity compared to metals such as copper or aluminum. Consequently, materials with superior electrical conductivity properties are commonly preferred for electrical purposes.

- Q: Stainless steel plate glued to tiles, what glue?

- In the choice of ceramic and metal bonding, customers will take into account whether the transparent and heat-resistant properties, metal is silver white, except for a few special colors, is solid at normal temperature (except mercury). Metals generally have good ductility, electrical conductivity, heat resistance (which are related to metal is a metal crystal). Ceramic stability, acid and alkali resistance, corrosion resistance, high temperature resistance, good insulation, high hardness.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The specific grade of stainless steel determines the maximum temperature that stainless steel sheets can endure. Typically, most stainless steel grades can handle temperatures up to approximately 1500°F (815°C) without significant oxidation or scaling. Nevertheless, some high-temperature stainless steel grades like 310 or 321 can endure temperatures up to 2100°F (1150°C) or even higher. To guarantee optimal performance and durability, it is crucial to consider the specific application and grade of stainless steel when determining its maximum temperature resistance.

- Q: Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Stainless steel is a type of metal alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface when exposed to air or moisture. This chromium oxide layer acts as a barrier, preventing oxygen from reaching the underlying metal and thus making stainless steel highly resistant to corrosion and fire. Stainless steel sheets have a melting point of around 2750°F (1510°C), which is significantly higher than the temperatures typically encountered in most fire scenarios. This means that stainless steel can withstand intense heat for a prolonged period without deforming or losing its structural integrity. Furthermore, stainless steel is non-combustible and does not contribute to the spread of flames. It does not release harmful gases or toxic fumes when exposed to fire, making it a safe material for use in various applications where fire resistance is crucial, such as in building construction, industrial equipment, and transportation. Due to these properties, stainless steel sheets are widely used in fire-rated structures, including fire doors, fire-rated walls, and fire-resistant enclosures. They provide an effective barrier against the heat and flames, helping to contain the fire and protect the surrounding areas. However, it is important to note that while stainless steel is highly resistant to fire, it can still be affected by extremely high temperatures or prolonged exposure to fire. In such cases, the material may experience some degree of distortion or damage. Therefore, it is essential to consider the specific fire rating requirements and consult with experts to ensure the appropriate selection and installation of stainless steel sheets in fire-resistant applications.

- Q: Are stainless steel sheets suitable for chemical processing plants?

- Yes, stainless steel sheets are highly suitable for chemical processing plants. Stainless steel is known for its excellent corrosion resistance, making it ideal for environments where chemicals are present. It is resistant to a wide range of chemicals, including acids, alkalis, and solvents, which are commonly used in chemical processing plants. Stainless steel sheets also offer high strength and durability, allowing them to withstand harsh operating conditions and maintain their structural integrity over time. They are also easy to clean and maintain, ensuring a hygienic environment in chemical processing plants. Additionally, stainless steel sheets have good thermal properties, making them suitable for applications involving high or low temperatures. They also exhibit low magnetic permeability, which can be beneficial in certain chemical processing operations. Overall, stainless steel sheets are a popular choice in chemical processing plants due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q: How do you prevent galvanic corrosion when using stainless steel sheets?

- One effective method to prevent galvanic corrosion when using stainless steel sheets is to ensure they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials or coatings, such as rubber gaskets or paint, between the stainless steel sheets and other metals. Additionally, regular maintenance and cleaning of the stainless steel surfaces can help prevent the accumulation of corrosive substances that could lead to galvanic corrosion.

- Q: What are the different types of stainless steel sheet finishes?

- There are several types of stainless steel sheet finishes, including No. 1, 2B, No. 4, BA, and satin.

- Q: Are stainless steel sheets suitable for pharmaceutical equipment?

- Indeed, stainless steel sheets prove to be appropriate for pharmaceutical equipment. The pharmaceutical industry extensively utilizes stainless steel owing to its exceptional resistance to corrosion, remarkable strength, and hygienic attributes. Its ease of cleaning and sterilization renders it perfect for applications that demand utmost cleanliness and product purity. Moreover, stainless steel displays resistance to chemicals and can endure extreme temperatures, thereby making it suitable for a multitude of pharmaceutical procedures. Furthermore, stainless steel sheets can be tailored in terms of thickness, size, and finish to fulfill precise equipment specifications. On the whole, stainless steel sheets deliver longevity, dependability, and the indispensable sanitary properties indispensable for pharmaceutical equipment.

- Q: How do you determine the hardness of stainless steel sheets?

- There are multiple methods available to determine the hardness of stainless steel sheets. The Rockwell hardness test is a commonly used method that involves measuring the depth of indentation on the material's surface. This is done by applying a specific load using a diamond cone or steel ball and measuring the resulting depth of penetration. The Rockwell hardness value is then determined based on this depth. Another method is the Vickers hardness test, which involves using a diamond indenter to create a square-shaped indentation. The size of this indentation is measured and converted into a hardness value. This method is often preferred for thin materials like stainless steel sheets. The Brinell hardness test is an alternative technique where a known load is applied to the material using a hardened steel ball. The resulting indentation's diameter is then measured, and the hardness value is calculated based on both the applied load and the diameter of the indentation. Apart from these mechanical tests, non-destructive methods such as ultrasonic hardness testing and magnetic hardness testing can also be employed. Ultrasonic testing determines the speed of sound through the material, which is then correlated to its hardness. Magnetic hardness testing, on the other hand, measures the magnetic properties of the material, which are affected by its hardness. Overall, the hardness of stainless steel sheets can be determined using various methods depending on the specific requirements and characteristics of the material.

- Q: How do you remove water spots from stainless steel sheets?

- Achieving water spot-free stainless steel sheets is simple with these steps: 1. Begin by thoroughly cleansing the surface using a mild dish soap and warm water solution. This will eliminate any dirt or grime that might contribute to the presence of water spots. 2. Rinse the sheets with fresh water and dry them completely using a soft cloth or towel. This is crucial to prevent the formation of new water spots during the cleaning procedure. 3. Subsequently, create a mixture of equal parts white vinegar and water. Immerse a clean cloth or sponge into the solution, ensuring to remove any excess liquid. 4. Gently rub the affected areas of the stainless steel sheets with the vinegar solution-soaked cloth or sponge. Make sure to follow the grain of the stainless steel in order to avoid scratching the surface. 5. Once the water spots have been rubbed, rinse the sheets with clean water and thoroughly dry them again using a soft cloth or towel. 6. If the water spots persist, you can attempt using a stainless steel cleaner or polish specifically formulated for eliminating stains and water spots. Follow the instructions provided with the cleaner and test it on a small, inconspicuous area beforehand to ensure it does not harm the stainless steel. Always remember to utilize soft materials and gentle cleaning techniques when dealing with stainless steel to prevent scratching or damaging the surface.

Send your message to us

201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords