Ceramic Fiber Board - 1800°C Industrial Furnace High Temperature Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

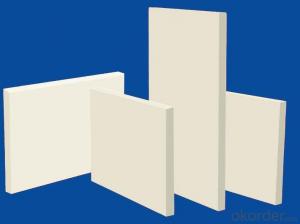

| Application: | Liners Of Industrial Furnace | Thickness: | 250-150mm | Width: | 400,500,600 |

| Length: | 600,1000 | Chemical Composition: | Al2O3+SiO2 | Working Temperature: | 1500-1800 |

| Place of Origin: | China (Mainland) | Brand Name: | Color: | White | |

| Ceramic Fibre Board: | Polycrystalline Mullite Fibre Board | Ceramic Fibre: | Ceramic Fibre Board | Characteristic: | Ultra High Temperature |

Packaging & Delivery

| Packaging Detail: | Wooden Carton |

| Delivery Detail: | 25days |

Characteristic:

PMF is a polycrystalline mullite fiber in the existing form of mullite crystalling phase, with a unique structure,

complicated manufacturing process and high technical content.

High temperature stability to 1600-1800C

Ideal for use as furnace insulation in sintering, heat treating and chemical thermal process systems

Non-Flammable

Excellent thermal shock resistance

Resistance to most chemical attack; it has excellent stability in acid metal slags and is insoluble in most acids

Resistance to oxidation and attack by furnace atmospheres

Resistance to abrasion

Good electrical resistivity

Excellent thermal stability

Can be used as insulation packing in furnace spaces and around furnace sight tubes & ports

Fill in expansion joints and masonry cracks inside of furnaces.

Technical Parameter:

Physical Data:

Items | FM-1600 | FM-1800 | |

Classification Temperature(oC) | 1600 | 1800 | |

Density(volume weight)(kg/m3) | 300-600 | 300-600 | |

Linear Contraction(%) | <2(1500oC×6h) | <1(1500oC×6h) | |

Chemical Composition | Al2O3 | 63.5 | 75 |

Al2O3+SiO2 | >99 | >99.5 | |

Fe2O3 ZrO2 | <0.1 / | <0.1 / | |

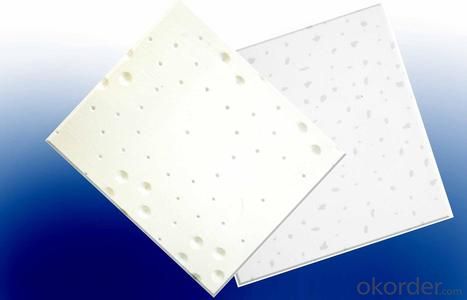

Standard Size:

Length×Width: 600×400, 1000×500, 1000×600(mm)

Thickness: 20-150(mm)

Advantages:

1. saving the energy

2. increasing the production

3. prolonging the life-span of the stove

4. improving the working atmosphere.

Application:

It is widely applied to the lining insulation of high temperature industrial kilns and other heat engineering equipment such as

metallurgy, machinery,electron, ceramic, chemical, glass, and aerospace.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board common specifications are: 600*400, 900*600, 1000*600 and 1000*1200mm, thickness 10/20/25/30/40/50mm, thinnest can do 6mm.Depending on the temperature range, it can be divided into:Common ceramic fiber board HLGX-164Standard ceramic fiber board HLGX-264High purity ceramic fiber board HLGX-364High alumina ceramic fiber board HLGX-464Ceramic fiber board containing zirconium HLGX-564

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

Send your message to us

Ceramic Fiber Board - 1800°C Industrial Furnace High Temperature Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords