1000C Micropores Insulation Board with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties.

It is an ideal back-up insulation for various industry where the high temperature is needed, with a long time exposure of 1150 °C at highest.

M5100 Panel ---Various coverings : Naked Panels, Aluminium Foil covering, E-class Fibre Cloth Covering, Fibre Paper covering.

M5100 Panel—Four Grades available : 850 , 1000, 1100, 1200

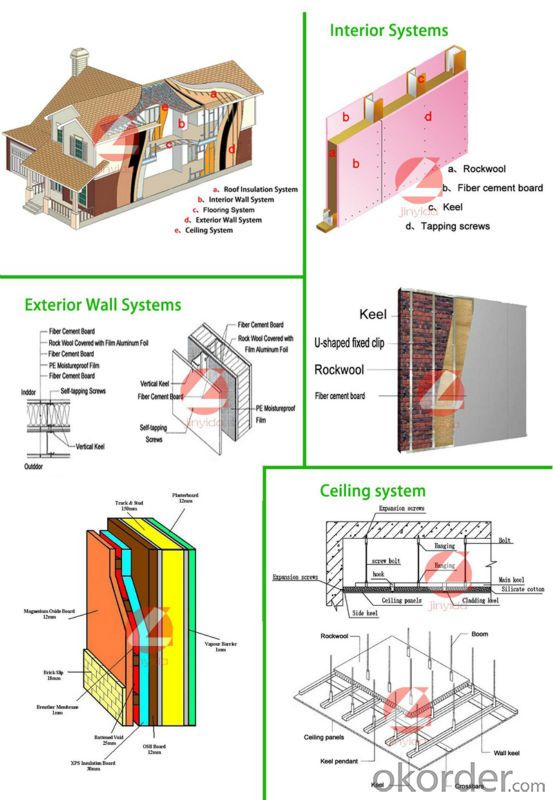

Product Applications:

Microporous Insulation Board are ideal for use in the below applications

Ladles

Torpedo Ladle

Tundish

Cement Rotary Kiln

Glass & ceramics industry

Petrochemical industry (cracking furnace, reformer)

Black box & VDR (Voyage Data Recorder)

Data loggers

Product Advantages:

CNBM has success in its Microporous Insulation Board due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

Extremely low thermal conductivity

High compressive strength

No harmful respirable fibres

Free of organic binders

Environmentally friendly

Product Specifications:

FAQ:

Q1: Why buy Microporous Insulation Board from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3.What is necessary for quotation?

A 3The info is the more detailed the better, like size, temp, al2O3 content etc.

Product Picture

Produce Processing

- Q: Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab crack (crack was autoclaved late cooling stage, it refers to the irregular surface crack, calcium silicate board, or bright or dark is likely to cause fracture, calcium silicate board, low strength, appearance and performance is not up to the requirements)The main reason for the crack is to cool down too quickly.Solution: control the cooling rate, slow exhaust steam.The above is the calcium silicate board equipment in the production of prone to stick, blank, cracks and other phenomena of the reasons and solutions, if you encountered similar problems in production, you can have some reference.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- It is not the appropriate material, calcium gypsum board to hemihydrate gypsum and organic silicone oil as the main material, the surface of the organic silicone oil with the installation way friction transportation will fall, a long time will get loss loss, if the poor quality of the organic silicone coating, it is not full proof effect is worse in the course of time, deformation, damp, moldy yes, yellow.

- Q: What are the raw materials of cement products? What's the function?

- Water is necessary for the production of cement products, the role of water is to cement hydration. Generally, the water cement ratio of concrete is 0.40~0.65. If the water is too large, it will leave a hole in the concrete, which will affect the strength, density and durability of the concrete and even cause water leakage.

- Q: What is the best price for the use of calcium silicate ceiling?

- Neither calcium silicate nor silicate boards are afraid of water because they are mixtures of gypsum and fiber.

- Q: What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What is the main role of fly ash added in concrete products?

- The rational use of fly ash in concrete, not only can replace part of cement, reduce the construction cost, but also because of its unique properties can be effectively used for the various requirements of the use of concrete, improve and enhance the performance of concrete.

- Q: How to make building glue?

- Universal type building adhesive and preparation method thereof, which is characterized in that the main components of the building glue: TDI, polyether, polyester, multiple resin, natural plant resin, polystyrene thin ester, solvent oil and ultraviolet resistant, anti-aging agent, component ratio (by weight) of:TDI2%--7%, 3%--8%, polyester polyether 1%--6%, multi resin 6%--15%, natural plant resin 6%--15%, polyphenyl ester 14%--25%, savanna solvent oil 10%--20%, anti UV, anti ageing agent 1%--4%.

- Q: What is dew point of thermal insulation material?

- The heat insulation lining has the characteristics of low thermal conductivity, small density, high flexibility, fire prevention, waterproof, etc..Light weight, 10 96kg/m3, 20kg/m3 following mat, 24 48kg/m3 as in hard, 48 96kg/m3 as core, which 48kg/m can fand a softening point of the ceiling, 500 degrees C, 300 degrees C insulation, the larger the amount, k=0.9.Calcium silicate insulation product was successfully developed in 70s. It has the characteristics of high compressive strength, small thermal conductivity, convenient construction and repeated use. It has been widely used in power systems.Most of the domestic universal small workshop production, have been imported from the United States after the four production lines, advanced technology, instant rejection speed fiber, dry needle felt, stable quality, high temperature 800 to 1250 DEG C.Features: acidity derivative of more than 2, high temperature resistant, general chemical pipe 1000 degrees C more, must use this material. The temperature is about 2000 C.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Foam heat insulation material mainly includes two categories, polymer foam type insulation material and foam asbestos insulation material. Polymer foam thermal insulation material has the advantages of small absorption rate, stable heat preservation effect, low thermal conductivity, no dust flying in construction, easy construction, etc., and it is in the period of popularization and application.

Send your message to us

1000C Micropores Insulation Board with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches