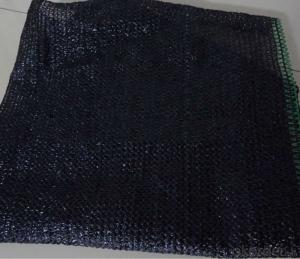

100% PE Waterproof Canvas for Tent Car use

- Ref Price:

-

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Quick Details

Material: 100% Polyester

Supply Type: Make-to-Order

Type: Tarpaulin

Pattern: Coated

Coated Type: HDPE Laminated

Style: Plain

Width: 70/75''

Technics: Woven

Feature: Blackout, Shrink-Resistant, Tear-Resistant, Waterproof, Anti-corrosion, Anti-aging

Use: Awning, Bag, Curtain, Industry, Military, Tent, Umbrella

Certification: Oeko-Tex Standard 100

Yarn Count: 800D

Weight: 80-260GSM

Density: 8*8,10*10,12*12

Model Number: Multiple

Material: PE

Width: 2-12m

Weight: 80-260GSM

Yarn Count: 850D

Colour: as required

Sizes: all kinds for choosing

Packaging & Delivery

| Packaging Details: | In bale, roll or carton |

|---|

| Delivery Detail: | Witnin 25 days after receiving desposit. |

|---|

Loading port: Qingdao

Delivery terms: FOB, CNF, CIF

Payment term: 30% TT in advance and balancebefore shipment.

Packing details: each piece pack into plastic bag with customizable lable, outside packing is roll or pe woven bag as customer request.

Loading container : 40ft container could load about 23 tons , 20ft container could load about 12 tons

- Q: Can olive nets be used in combination with pest monitoring techniques?

- Yes, olive nets can be used in combination with pest monitoring techniques. Olive nets are primarily used to protect olive trees and their fruits from pests and birds. By using olive nets, farmers can physically prevent pests from accessing the trees, reducing the need for chemical pesticides. Additionally, by combining olive nets with pest monitoring techniques such as traps or pheromone-based monitoring systems, farmers can gain a better understanding of pest populations and their behavior. This integrated approach allows for more effective pest management and a more sustainable olive farming practice.

- Q: Can olive nets be used for different varieties of olives?

- Yes, olive nets can be used for different varieties of olives. Olive nets are designed to catch falling olives during harvest, regardless of the specific variety being cultivated. They provide a practical and efficient method for collecting olives, ensuring minimal damage to the fruit and facilitating easier harvesting.

- Q: Can olive nets be used for decorative purposes in gardens?

- Yes, olive nets can be used for decorative purposes in gardens. The nets can be draped over plants, trees, or structures to create a visually pleasing effect. Additionally, they can add a rustic or Mediterranean touch to the garden aesthetics.

- Q: How long can an olive net last?

- The lifespan of an olive net can vary depending on various factors such as the quality of the net, its maintenance, and the environmental conditions it is exposed to. On average, a well-maintained olive net can last for several years, providing effective protection during each harvest season.

- Q: Do olive nets require any specific cleaning or washing procedures?

- Yes, olive nets require specific cleaning procedures. They should be washed with mild soap and warm water to remove dirt, debris, and olive residue. It is important to avoid using harsh chemicals or abrasive materials that could damage the nets. After cleaning, they should be thoroughly rinsed and left to air dry before storage to prevent mold or mildew growth.

- Q: Where can you purchase olive nets?

- Olive nets can be purchased from various sources such as agriculture supply stores, online marketplaces, gardening centers, and specialized olive farming equipment suppliers.

- Q: Can olive nets be used in conjunction with mechanical olive harvesters?

- Yes, olive nets can be used in conjunction with mechanical olive harvesters. Olive nets are commonly used to collect olives that are mechanically harvested from the trees. These nets are spread out on the ground beneath the trees to catch the falling olives, ensuring that they are not damaged or lost during the harvesting process. The combination of mechanical harvesters and olive nets allows for efficient and effective olive harvesting while maintaining the quality of the harvested olives.

- Q: Can olive nets be used on trees with a tall height?

- Yes, olive nets can be used on trees with a tall height. Olive nets are designed to be draped over the trees and can be adjusted or extended to accommodate trees of varying heights.

- Q: Can olive nets be repaired if they become damaged?

- Yes, olive nets can be repaired if they become damaged. The repair process typically involves mending tears or replacing damaged sections of the net to ensure its effectiveness in harvesting olives.

- Q: How do olive nets protect olives from wind damage?

- Olive nets protect olives from wind damage by creating a barrier that prevents the wind from directly hitting the fruits. The nets act as a shield, reducing the impact of strong winds and preventing them from dislodging or damaging the olives.